Aluminum wheel water cooling low-pressure casting die and technology

A low-pressure casting and water-cooling technology, which is applied in the field of aluminum alloy casting, can solve problems such as low casting production efficiency, noise pollution in casting working conditions, and low performance and quality of casting materials, so as to improve casting efficiency, eliminate noise pollution, and improve casting working conditions conditional effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

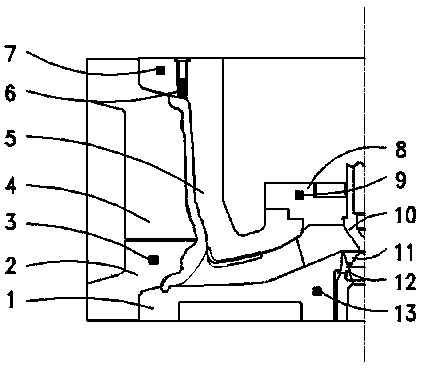

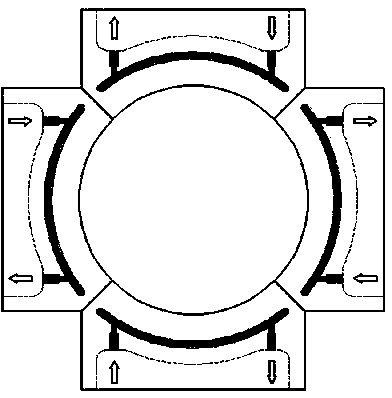

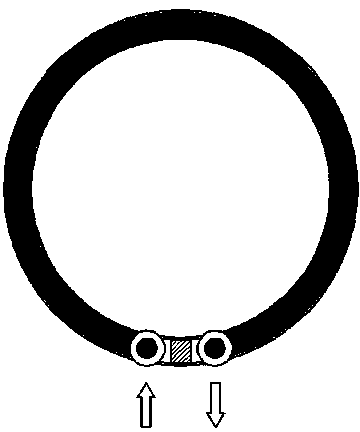

[0028] The technical solution of the present invention is that the aluminum wheel low-pressure casting water-cooled mold includes a bottom mold 1, a lower mold 2, an upper mold 4, a top mold 5, a center movable block 8, an injection sprue sleeve 12, a filter screen 11, and a diverter cone 10 , exhaust plug 6, the bottom mold 1 is provided with a pouring sprue sleeve 12 and a water cooling channel 13 for cooling the spokes, the central movable block 8 and the splitter cone 10 are arranged on the top mold 5, and the central movable block 8 is arranged Water-cooling channel 9 for cooling the wheel core, the Top mold 5 The upper outer edge is provided with an exhaust plug 6 and a water cooling channel 7 for cooling the inner wheel rim. The side mold is divided into an upper side mold 4 and a lower side mold 2. The lower side mold 2 is provided wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com