Board incoming control method and device for horizontal line and horizontal line

A horizontal line and board control technology, applied in the field of horizontal lines, can solve the problem of large pitch error and achieve the effect of overcoming large pitch error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

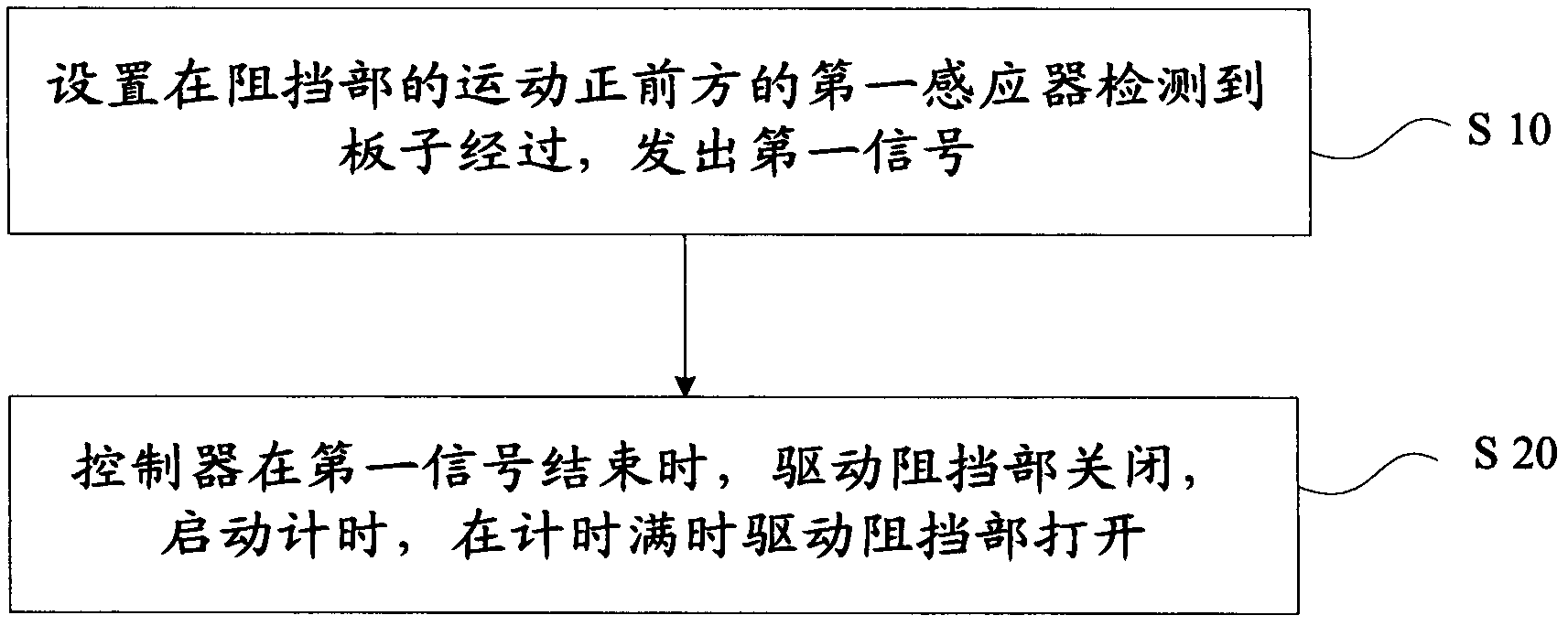

[0015] figure 1 It shows a flow chart of a method for controlling board entry of a horizontal line according to an embodiment of the present invention, including:

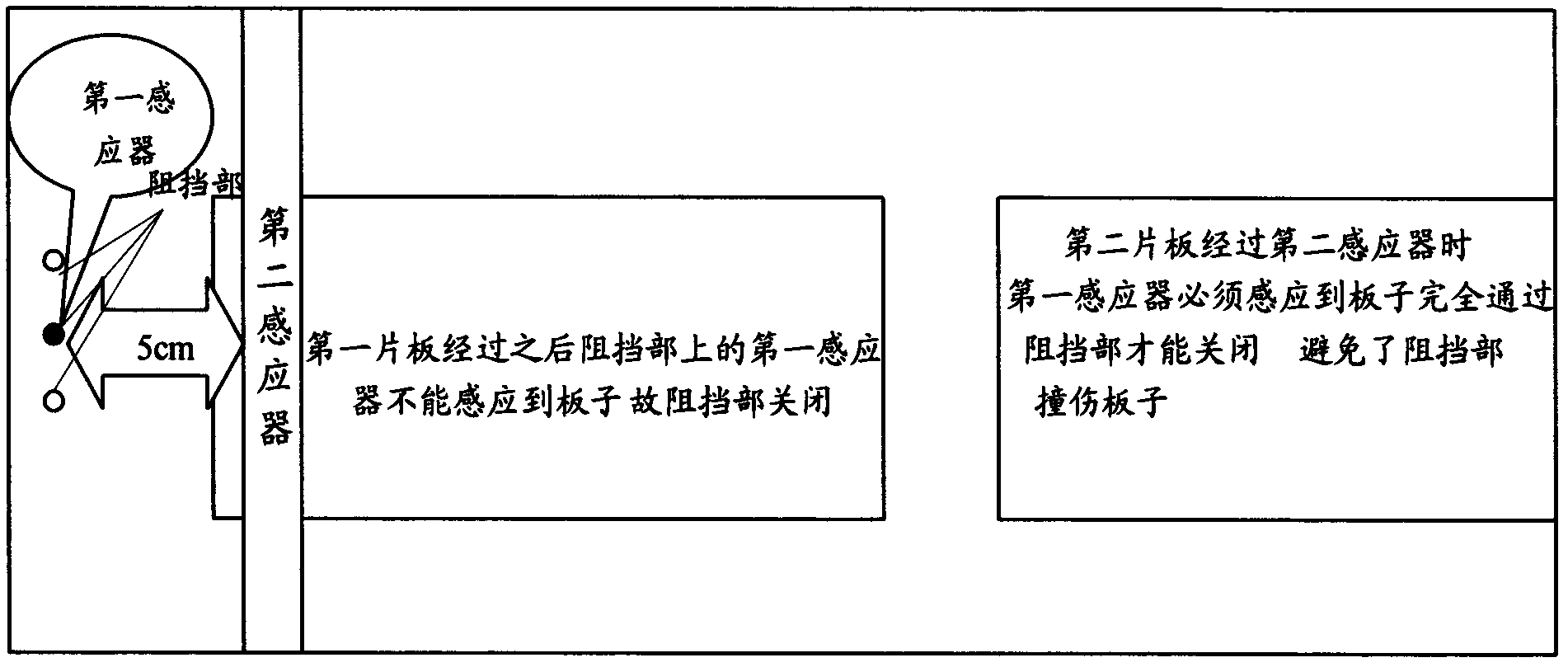

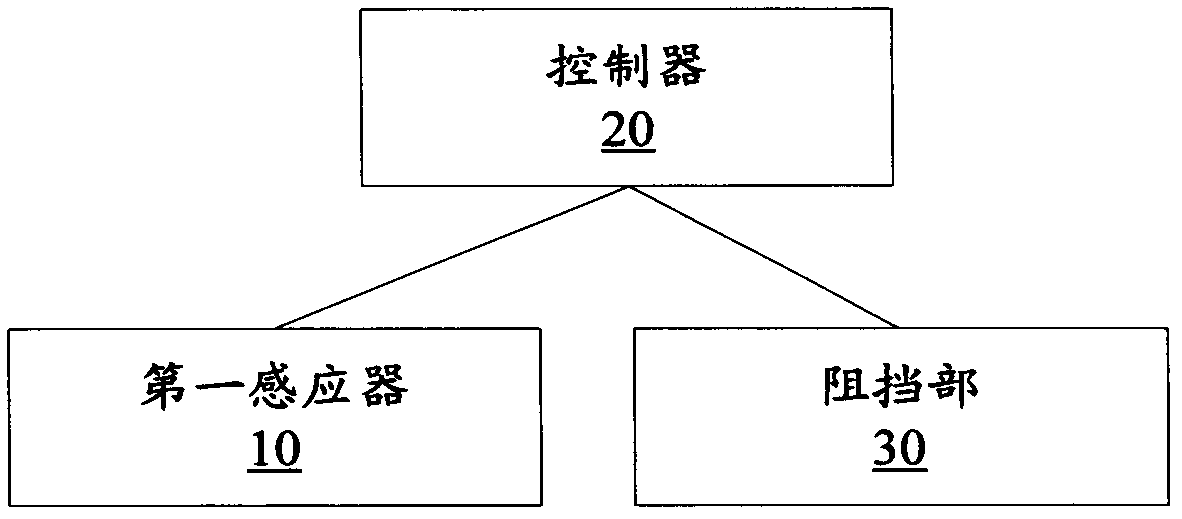

[0016] Step S10, the first sensor arranged in front of the movement of the blocking part detects the passing of the printed circuit board and sends out a first signal, wherein the blocking part is arranged at the entry end of the horizontal line;

[0017] Step S20, when the first signal ends, the controller drives the blocking part to close, starts the timer, and drives the blocking part to open when the timer expires.

[0018] In this embodiment, even if there is a large spacing error in manual casting, the action of the blocking part can be controlled through the timing set in advance according to the optimal working condition, so as to adjust the spacing of the panels...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com