Method and device for homogenizing the solidified structure of a large ingot with a static magnetic field combined with a rotating magnetic field

A technology of rotating magnetic field and solidification structure, which is applied in the field of metal solidification technology and its devices intervened by external magnetic field, can solve the problems of stirring paddle solidification biting, uneven distribution of crystal nuclei, electromagnetic stirring attenuation, etc., and achieve the improvement of comprehensive mechanics and physics. Performance, improvement of tissue and composition uniformity, effect of increasing tissue uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

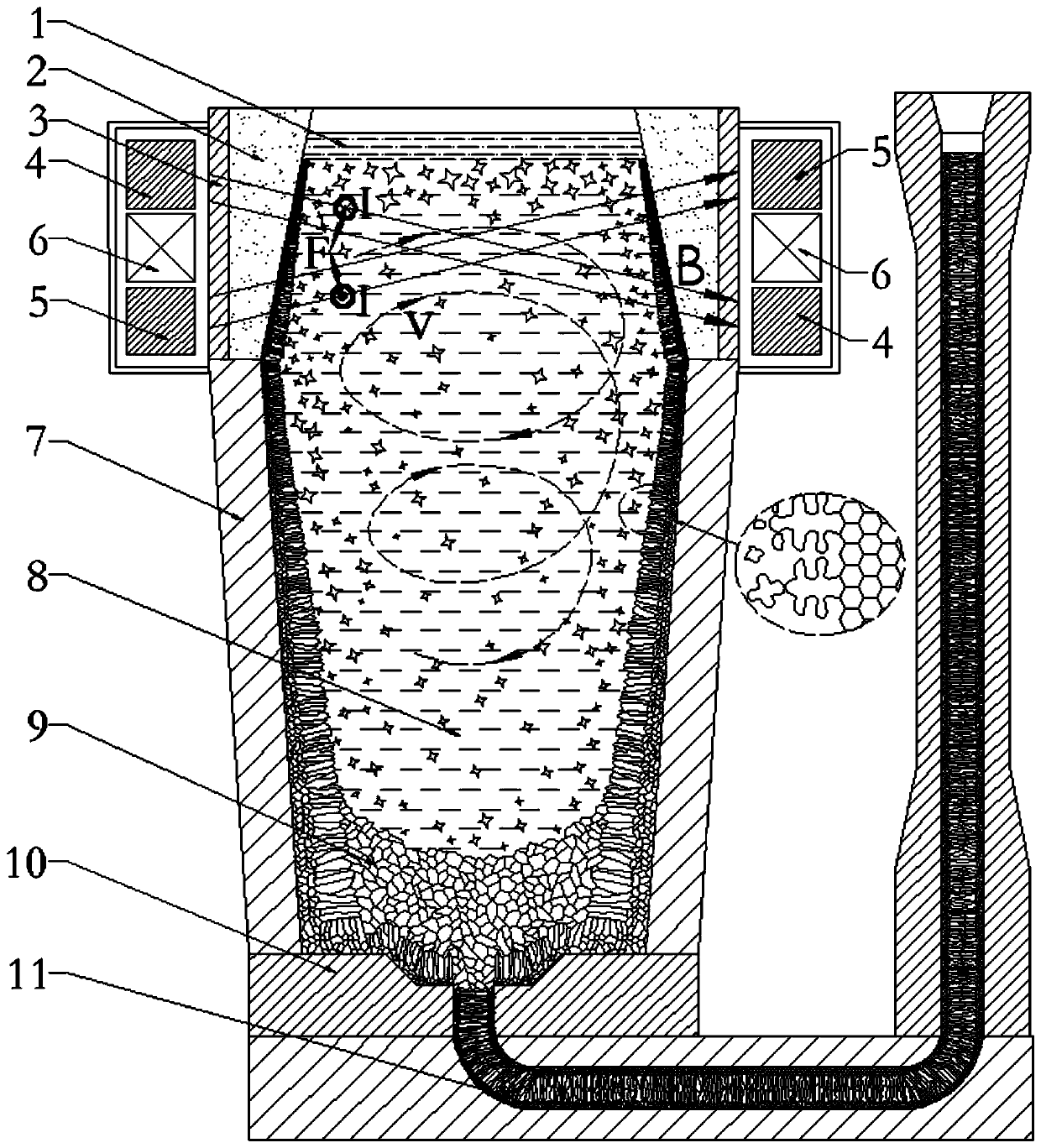

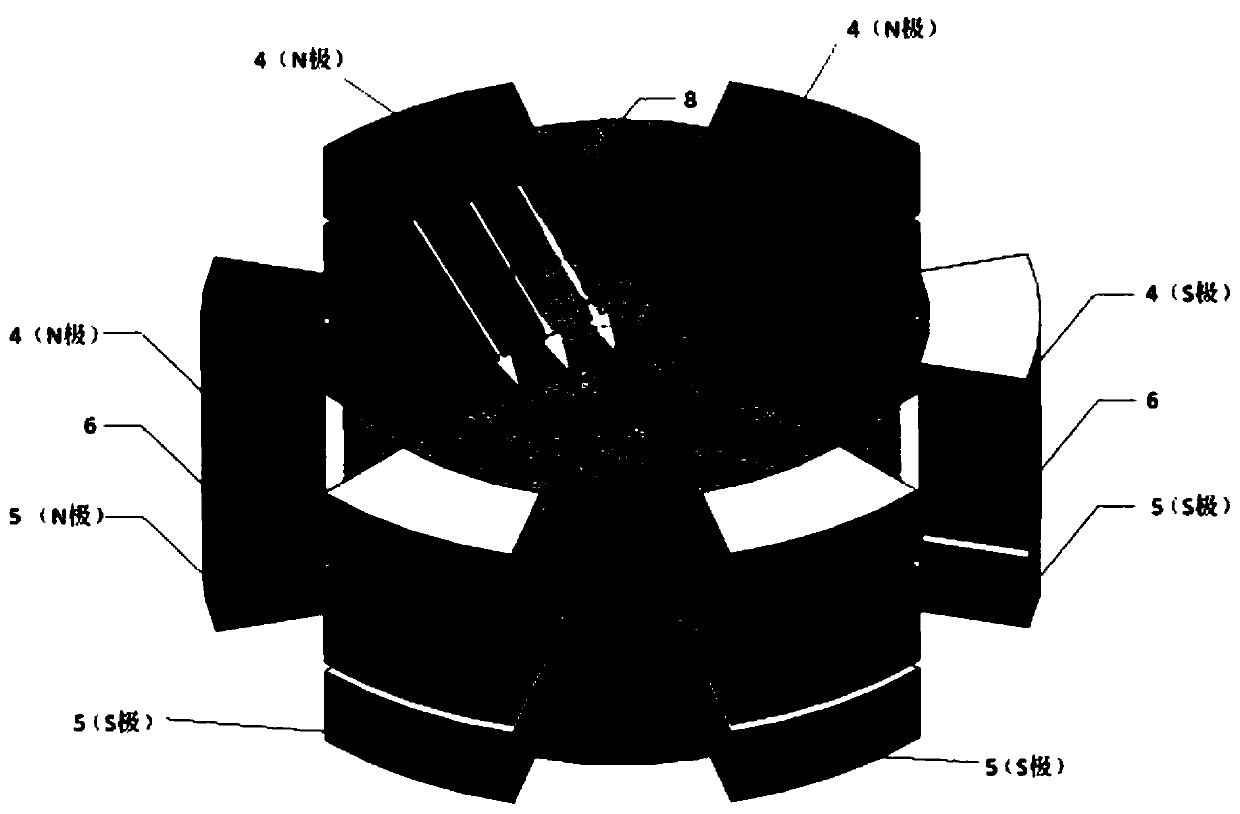

[0035] In this example, see figure 1 and figure 2, a device for preparing a large ingot by applying a static magnetic field combined with a rotating magnetic field, comprising a metal ingot mold 7 and an ingot mold base 10, molten metal 8 injected into the cavity of the metal ingot mold 7, and the ingot mold base 10 supporting the entire metal ingot mold 7 , connect and install the riser insulation cover composed of the riser shell 3 and the insulation brick 2 stacked on the open edge of the metal ingot mold 7, the insulation brick 2 is directly in contact with the shallow metal liquid 8, and the metal liquid in the riser insulation cover The surface of 8 is covered with a layer of covering slag 1 to form a riser insulation system composed of covering slag 1 and insulation brick 2, so that the insulation brick 2 is enclosed to form a riser wall, and a riser area is formed inside the riser wall. A static magnetic field generator and a rotating magnetic field generator 6 are a...

Embodiment 2

[0044] This embodiment is basically the same as Embodiment 1, especially in that:

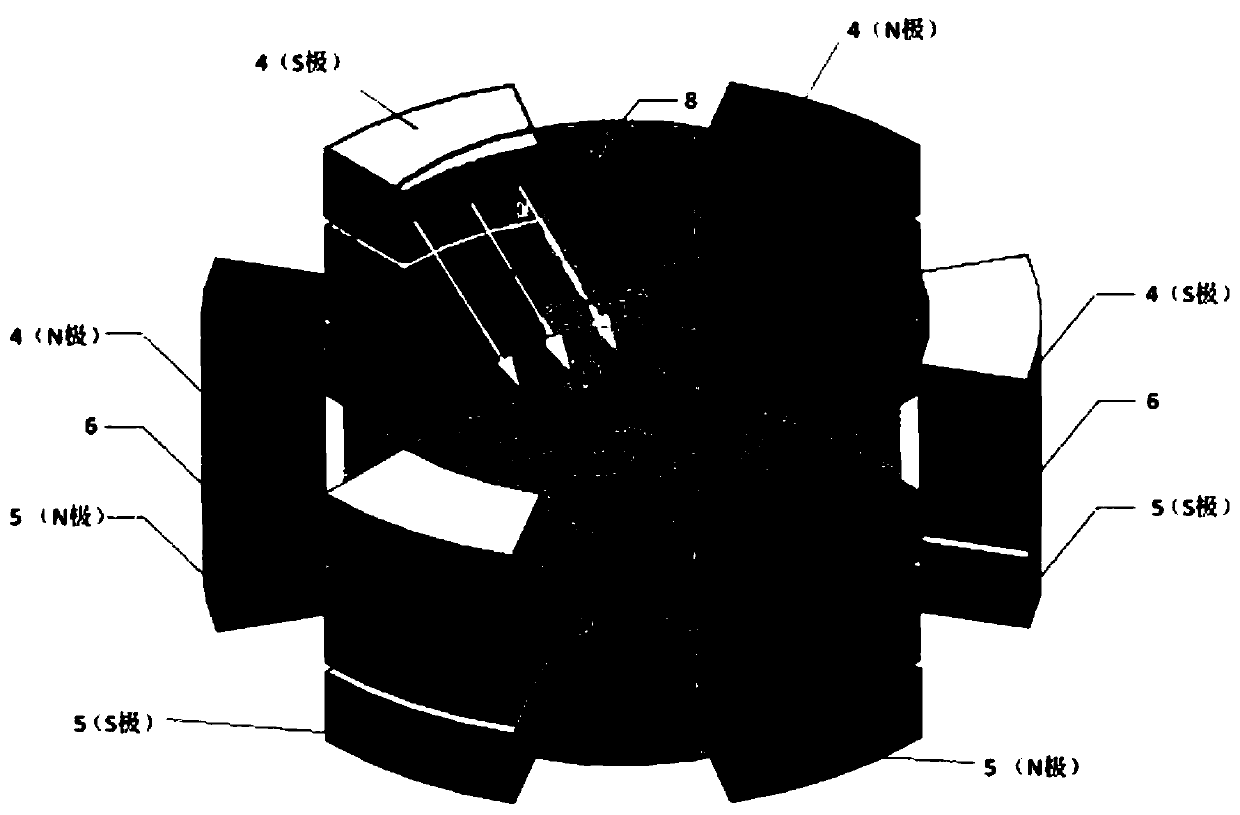

[0045] In this example, see image 3 The static magnetic field device unit with the same name of the magnetic pole and the static magnetic field device unit with the different name of the magnetic pole are adjacent to each other, and are arranged around the periphery of the riser casing 3 in turn, so that the static magnetic field device units arranged on the periphery of the riser casing 3 form "N-S-N-S ” Form of magnetic poles staggered arrangement. In this embodiment, the magnetic poles are arranged in a staggered manner, so that the circumferential composition and temperature of the ingot are more uniform, and the electromagnetic stirring effect is more significant.

[0046] In this example, a static magnetic field combined with a rotating magnetic field is used to prepare a solidified structure of a large ingot through homogenization treatment. The electromagnetic oscillation generated by...

Embodiment 3

[0048] This embodiment is basically the same as the previous embodiment, and the special features are:

[0049] In this embodiment, the height of the air gap between the magnetic poles is adjustable, and the opening and closing distance between the upper magnetic pole 4 and the lower magnetic pole 5 is controlled by a controllable mechanical device to realize clamping between the magnetic force lines in the first direction and the magnetic force lines in the second direction. The angle of the angle is controlled to obtain a more abundant combination of magnetic force lines of the composite magnetic field, so that the special composite magnetic field can be set and adjusted according to the preparation requirements of different metal materials. The solidification structure is significantly refined, porosity and shrinkage cavity are eliminated, macro segregation is reduced or even suppressed, shrinkage stress during ingot solidification is reduced, and crack formation is prevente...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com