Homogenized copper-nickel-tin alloy rod and preparation method thereof

A technology of alloy rods and copper-nickel-tin, which is applied in the field of homogenized copper-nickel-tin alloy rods and its preparation, can solve the problems of cumbersome alloy process, immature preparation technology, and no application, and achieve short process routes, Effect of reducing macro segregation and reducing micro segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

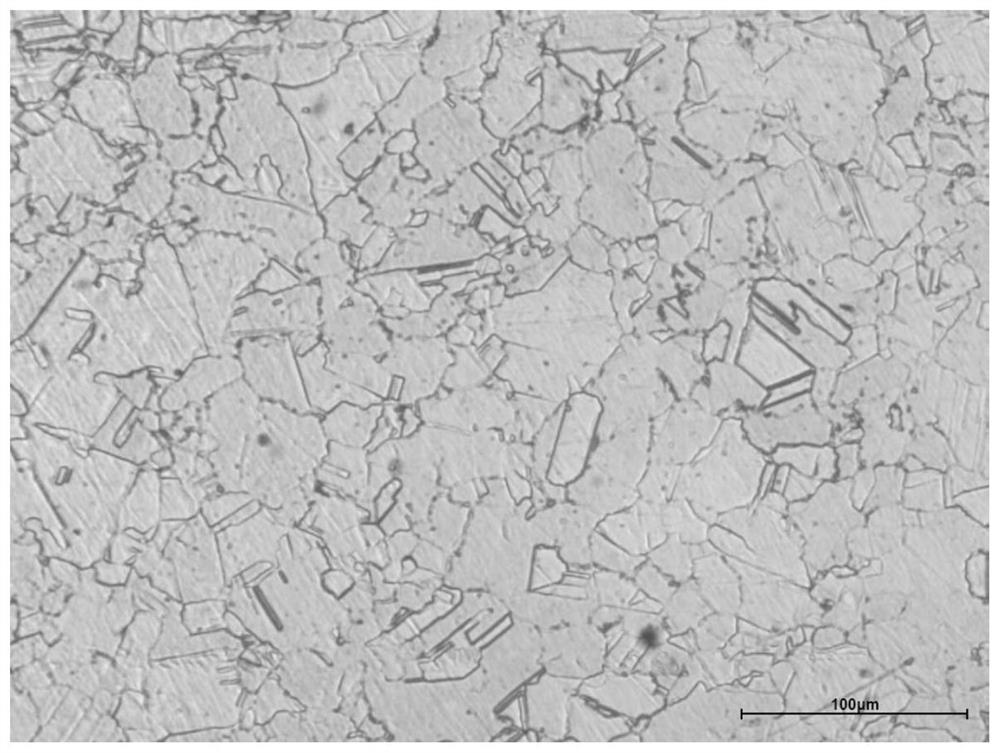

Embodiment 1

[0021] A preparation method of a homogenized copper-nickel-tin alloy bar comprises the steps:

[0022] (1) Ingredients step: In terms of mass percentage, Zn is 0.026%, Sn is 7.9%, Nb is 0.03%, Ni+Co is 14.8%, Fe is 0.01%, Mg is 0.001%, and the rest is Cu, and Co It accounts for 0.1% of the total mass of Ni+Co.

[0023] (2) Melting step: use a vacuum induction furnace for melting, first add the raw materials prepared according to the formula in step (1): Cu, Sn, Nb, Fe and the remainder of Ni into the crucible, vacuumize to below 10Pa and start heating Refining is carried out until the alloy is completely melted, the refining temperature is controlled at 1350°C, the refining time is controlled at 5min, filled with argon, and then Ni-Mg alloy (in Ni-Mg alloy, the mass ratio of Ni to Mg is 3:1) is added In the alloy melt, wait for it to dissolve and keep warm for 3 minutes. After the ingot is poured, the vacuum is broken immediately, and the ingot is cooled rapidly by air cooli...

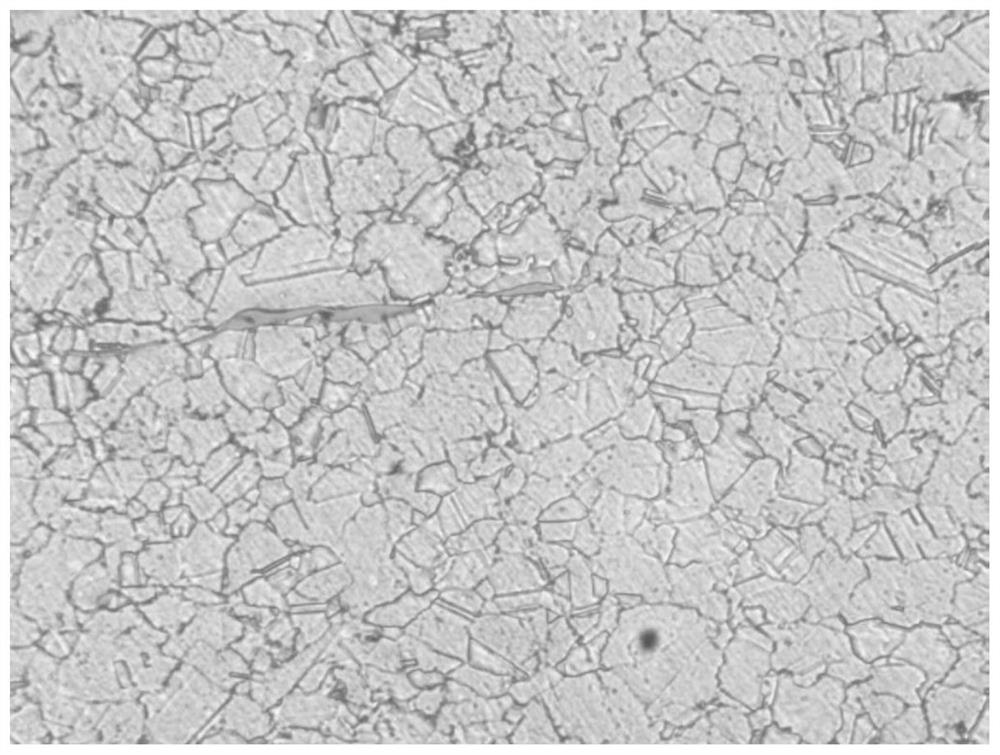

Embodiment 2

[0031] A preparation method of a homogenized copper-nickel-tin alloy bar comprises the steps:

[0032] (1) Ingredients step: In terms of mass percentage, Zn is 0.01%, Sn is 8.2%, Nb is 0.05%, Ni+Co15.0%, Fe is 0.02%, Mg is 0.008%, the rest is Cu, and Co It accounts for 3.0% of the total mass of Ni+Co.

[0033] (2) Melting step: use a vacuum induction furnace for melting, first add the raw materials prepared according to the formula in step (1): Cu, Sn, Nb, Fe and the remainder of Ni into the crucible, vacuumize to below 10Pa and start heating Refining until the alloy is completely melted, the refining temperature is 1300°C, the refining time is 6min, filled with argon, and then the Ni-Mg alloy (in the Ni-Mg alloy, the mass ratio of Ni to Mg is 4:1) is added to the alloy melt , to be cleared, keep warm for 3 minutes, after the ingot is poured, immediately break the vacuum, and use the air cooling method to quickly cool the ingot;

[0034] (3) Homogenization treatment step: re...

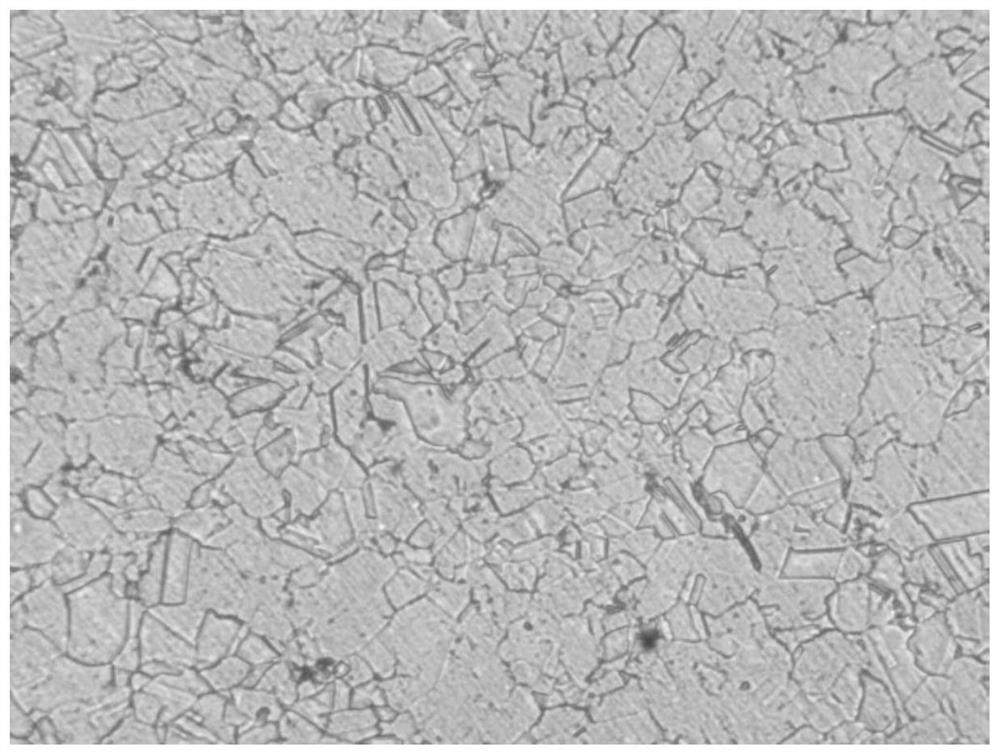

Embodiment 3

[0041] A preparation method of a homogenized copper-nickel-tin alloy bar comprises the steps:

[0042] (1) Ingredients: In terms of mass percentage, Zn is 0.02%, Sn is 8.0%, Nb is 0.02%, Ni+Co is 15.1%, Fe is 0.02%, and Mg is 0.015%. The rest is Cu, and Co accounts for 5.0% of the total mass of Ni+Co.

[0043] (2) Melting: use a vacuum induction furnace for melting, first add the raw materials prepared according to the formula in step (1): Cu, Sn, Nb, Fe and the rest of Ni into the crucible, vacuumize to below 10Pa and start heating to The alloy is completely melted and refined, the refining temperature is 1310°C, the refining time is 5min, filled with argon, and then the Ni-Mg alloy (in the Ni-Mg alloy, the mass ratio of Ni to Mg is 3.5:1) is added to the alloy melt, To be clear, keep warm for 3min. After the ingot is poured, the vacuum is broken immediately, and the ingot is cooled rapidly by air cooling;

[0044] (3) Homogenization treatment: Remove the riser and shrinka...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com