Rub type shelling and sorting machine for camellia fruits

A technology of camellia fruit and sorting machine, which is applied in the directions of shelling, solid separation, sieving, etc., can solve the problems such as the failure of small fruit, the high crushing rate of seed kernels, and the poor shelling effect, and achieves compact structure and convenient use. Convenience and high productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

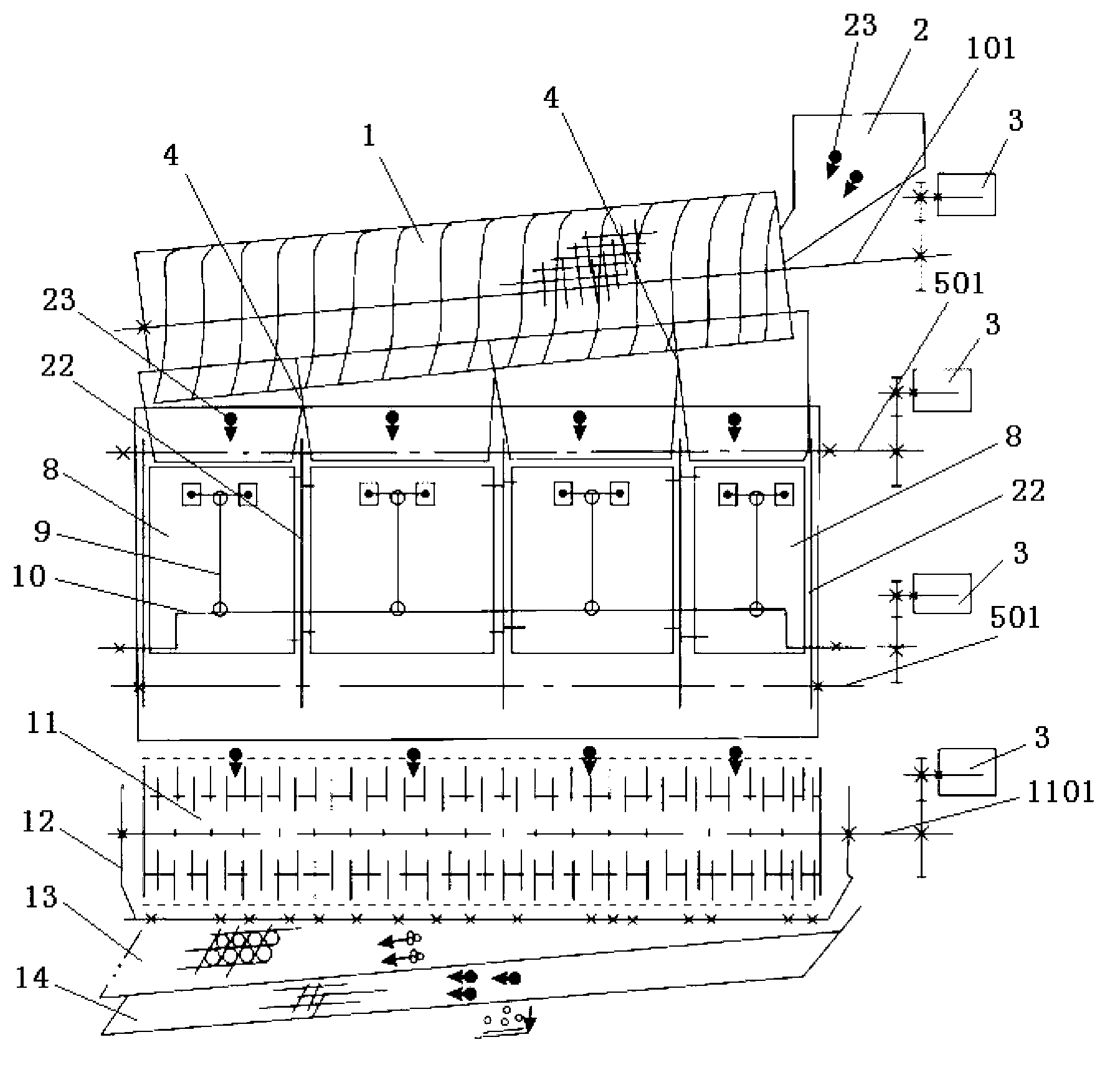

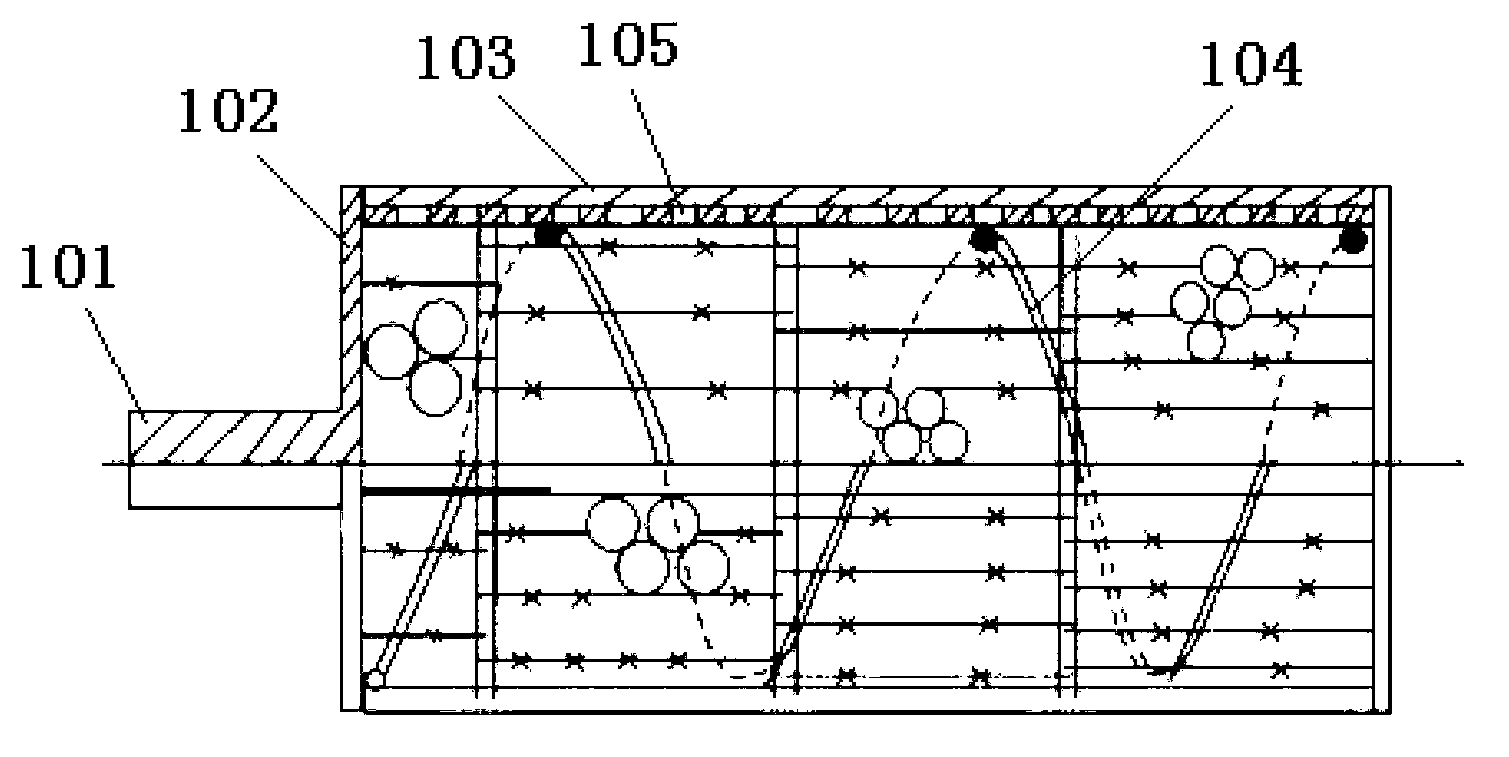

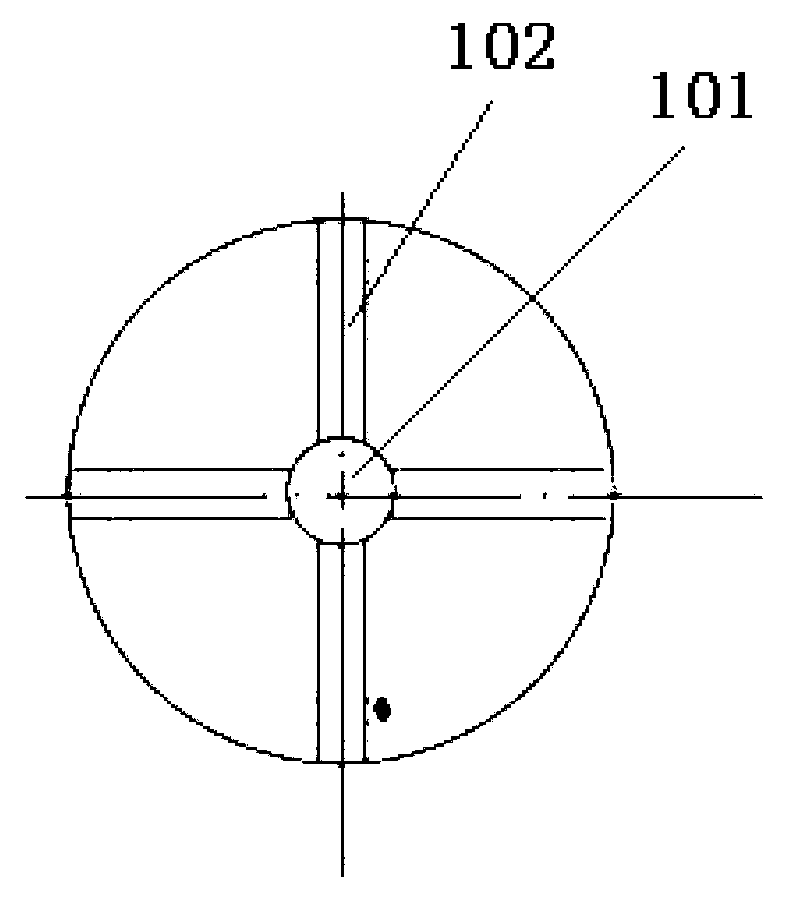

[0025] see figure 1 , the present embodiment includes Camellia oleifera fruit sorting rolling screen 1, the main shaft 101 of Camellia oleifera fruit sorting rolling sieve 1 is installed obliquely on the horizontal plane, the higher end opening of Camellia oleifera fruit sorting rolling sieve 1 is connected with Camellia oleifera hopper 2; Camellia oleifera fruit sorting rolling sieve 1 The main shaft 101 is connected with the motor and the speed changer 3 . see figure 2 , image 3 Camellia oleifera classification rolling screen 1 comprises a cage frame made up of radial supports 102 and longitudinal steel bars 103, its main shaft 101 is a half shaft, and is fixed on the central axis of the cage frame, and fixed on the inner circumference of the cage frame. Helical protruding ribs 104 are connected. from figure 2It can be seen from the figure that the sieve mesh 105 of the camellia oleifera fruit classification rolling screen 1 of the present embodiment is divided into f...

Embodiment 2

[0030] see Figure 7 , Figure 8 , the other components of this embodiment are the same as those of Embodiment 1, the difference is that Figure 7 with Figure 8 The structure and the mode of motion of the flexible rubbing plate in the shown rubbing camellia oleifera fruit shelling device are different. from Figure 7 , Figure 8 It can be seen in the figure that two eccentric shafts 16 are fixedly connected to each flexible rubbing plate 15 respectively, and the eccentric shafts 16 are all connected with the power transmission mechanism 17, and the eccentric shafts 16 are perpendicular to the flexible surface under the power of the power transmission mechanism 17. The axis of the conveyor belt 18 planes is a rotating shaft for rotating motion, and drives each flexible rubbing plate 15 to perform a rotary circular rubbing motion relative to the flexible surface conveyor belt 18 planes. Wherein, between each flexible rubbing board 15 and both ends also be provided with par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com