Integrated machine for shelling and peeling lotus seed

An all-in-one machine and lotus seed technology, applied in the fields of shelling, pod removal, food science, etc., can solve the problems of one-stop peeling, inability to peel lotus seeds, troublesome operation, etc., achieve the effect of compact machine structure and improved lotus production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

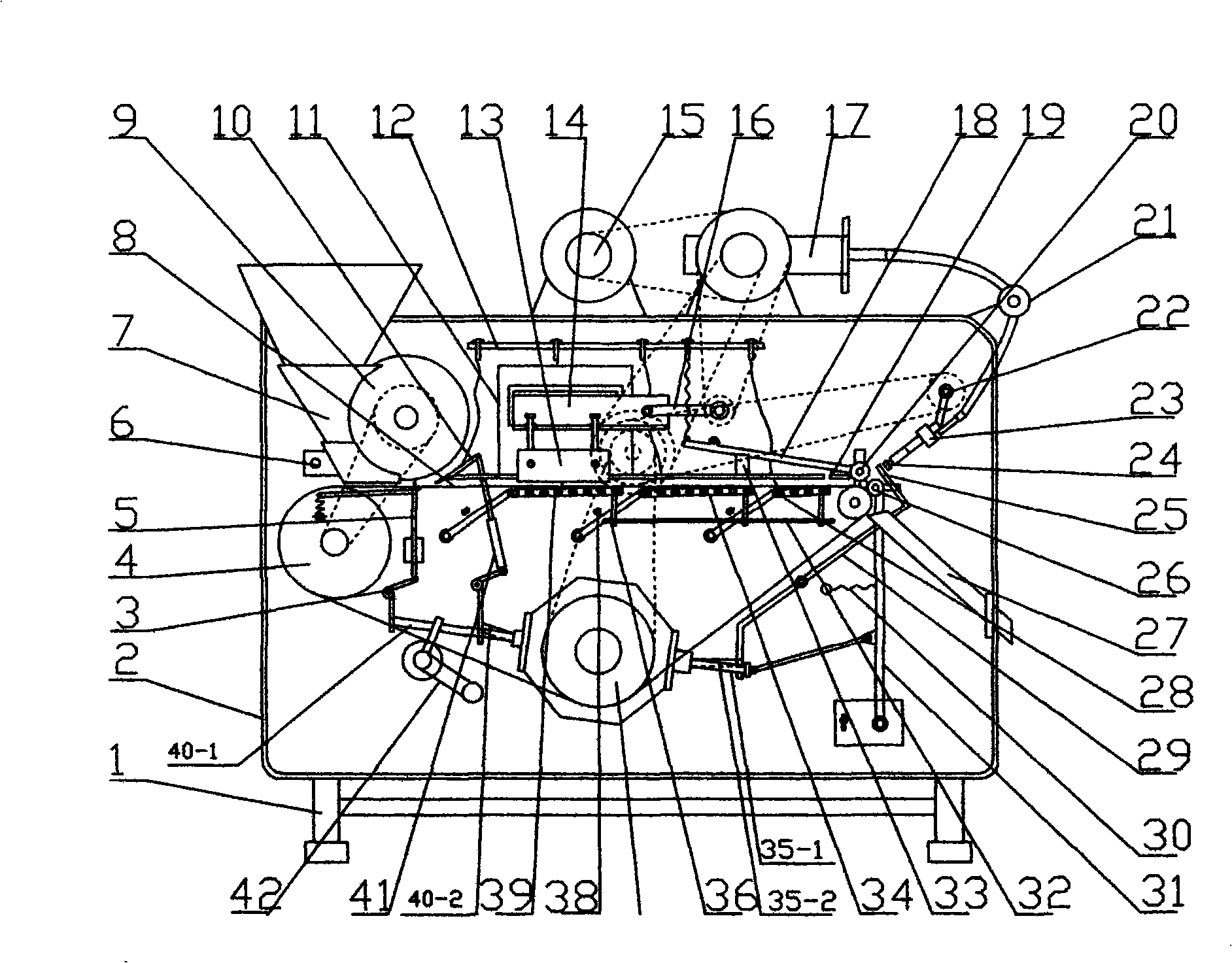

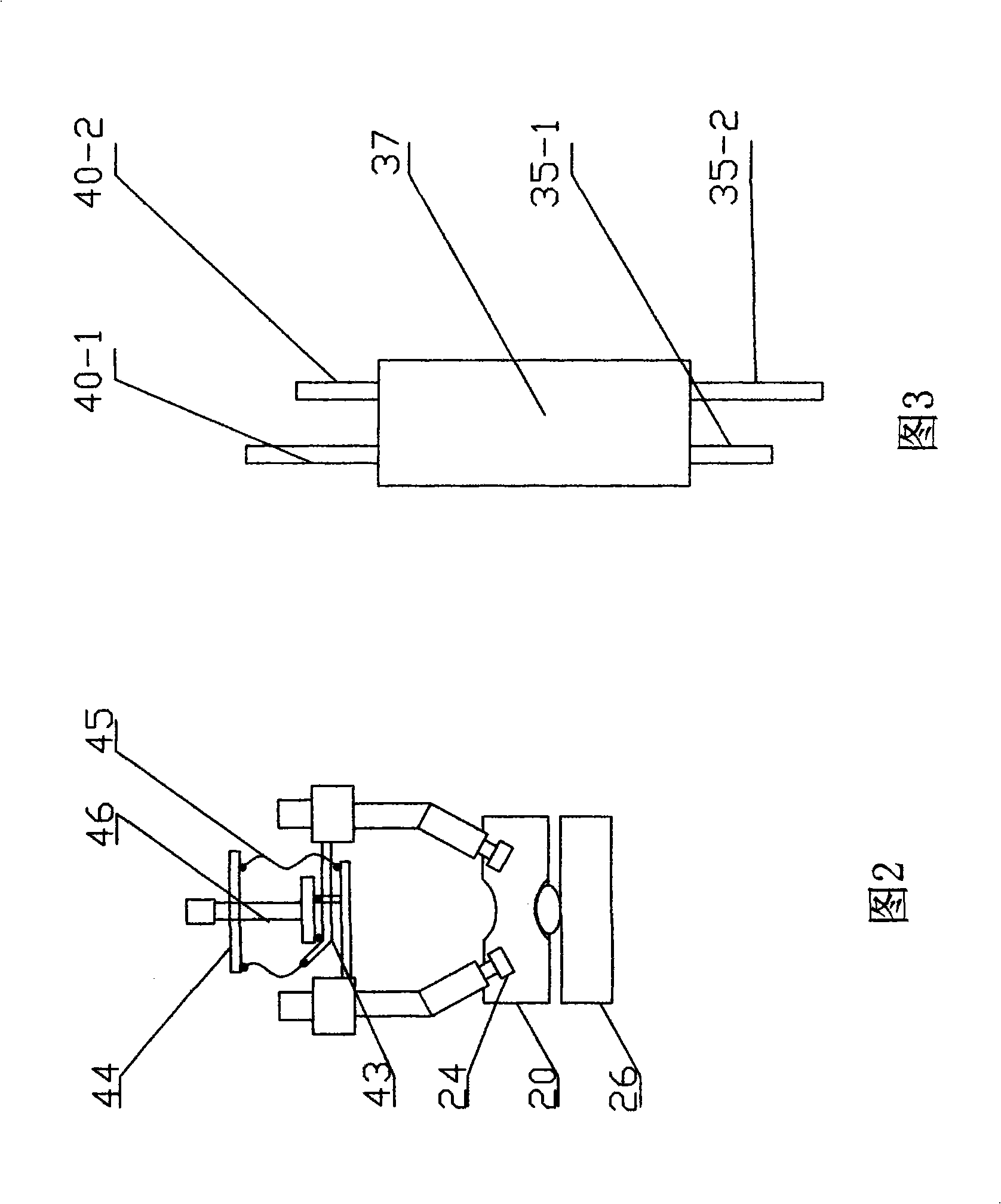

[0011] Embodiment 1: it comprises tripod 1, body 2, conveyer belt 8, funnel 7, water pump 17 and power unit and power transmission system, mainly consists of lotus seed positioning device, distance setting device, sawing device, shelling device, peeling device and The transmission device consists of a lotus seed positioning device and a peeling device respectively located at the two ends of the transmission device, and a spacing device, a sawing device and a shelling device are arranged side by side above the working surface of the conveyor belt 8 in the transmission device, and the positioning device and the spacing device The top of the working surface of the conveyor belt 8 between the sawing device and the sawing device is correspondingly provided with a transmission guide rail. After the lotus seeds are positioned by the positioning device, they are respectively rolled and transported to the distance setting device, the sawing device, and the shelling device by the conveyor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com