Desulfurization waste liquid acid making system and method

A technology of desulfurization waste liquid and concentrated sulfuric acid, which is applied in chemical instruments and methods, sulfur compounds, inorganic chemistry, etc., can solve the problems of secondary pollution resources, waste, dilute sulfuric acid cannot be directly used, etc., achieve high sulfur recovery rate, reduce SO2 temperature, the effect of improving resource utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

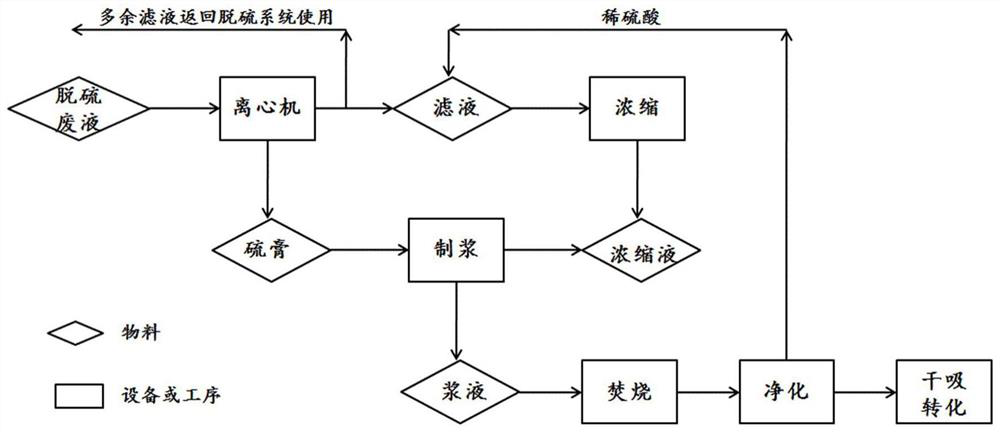

[0030] Such as figure 1 As shown, the desulfurization waste liquid acid production system includes a pretreatment unit that separates the desulfurization waste liquid from the desulfurization unit into sulfur paste and filtrate, a concentration unit that concentrates the filtrate to obtain a concentrate, and mixes the sulfur paste and concentrate to form a slurry The pulping unit, incinerating the slurry to produce SO 2 Gas incineration unit, for SO 2 The purification unit for gas scrubbing, the purified SO 2 The dry absorption conversion unit where the gas is made into concentrated sulfuric acid and the waste heat recovery unit located between the incineration unit and the purification unit. The dilute sulfuric acid outlet in the purification unit is connected to the filtrate storage tank for storing the filtrate in the pretreatment unit. The pretreatment unit is equipped with a centrifuge for separating sulfur paste and filtrate, and the incineration unit is equipped with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com