Sulfur recovering heat utilization device and method

A sulfur recovery and heat technology, applied in lighting and heating equipment, sulfur preparation/purification, sustainable manufacturing/processing, etc., can solve the problems that affect the sulfur recovery device sulfur yield, reduce efficiency, and cannot further reduce the temperature, etc. Achieve the effect of reducing influence, reducing load and preventing the temperature from being too low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

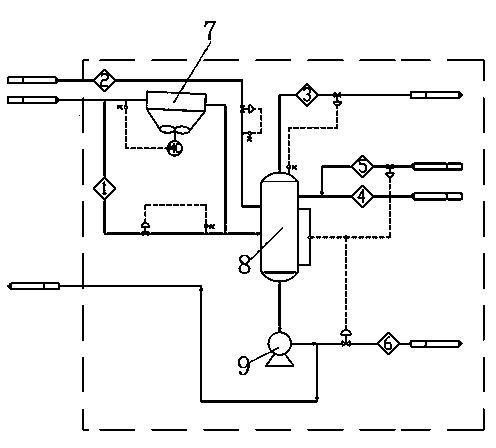

[0026] A sulfur recovery heat utilization device, such as figure 1 As shown, it includes: a steam air cooler 7, a condensed water recovery tank 8 and a condensed water pump 9 connected in sequence; There is a height difference between the water outlet and the inlet of the condensed water recovery tank; the condensed water recovery tank 8 is connected to the steam reheater in the sulfur recovery device through the pipeline 2, and the condensed water recovery tank 8 is provided with a pressure regulating and venting pipeline on the tank top 3. The condensed water recovery tank 8 is connected to the steam traps of the sulfur recovery device through the pipeline 4, and the condensed water recovery tank 8 is connected to the low-pressure boiler feed water of the factory system through the replenishment pipeline 5; the condensed water pump 9 is connected to the low-pressure boiler through the pipeline 6 It is connected with the condensate pipe network of the factory, and the condens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com