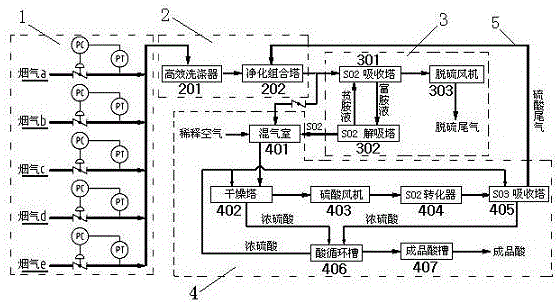

Process flow of comprehensive recovery of low-concentration SO2 flue gas from multiple gas sources

A process flow, SO2 technology, applied in the direction of sulfur compounds, inorganic chemistry, dispersed particle separation, etc., to achieve the effect of promoting development, high sulfur recovery rate, and optimizing equipment and investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0034] Embodiment: below with tin smelting process O furnace, fuming furnace, fluidized bed furnace contain SO 2 The comprehensive recovery of flue gas to produce acid is taken as an example to illustrate the process flow.

[0035] Such as figure 1 As shown, the low-concentration SO 2 The flue gases a, b, c, d, and e are mixed into the high-efficiency scrubber 201 after pressure adjustment, and in the process of colliding with the liquid reversely sprayed by the large-diameter nozzle, the purification of the flue gas and the adjustment of the flue gas temperature are realized. Then the saturated wet flue gas enters the packed washing tower at the lower part of the purification combined tower 202, and exchanges heat with the washing liquid and flue gas sprayed from top to bottom on the surface of the packing, so that the temperature of the flue gas drops to about 40°C and enters the purification process. Combine the electric demister on the upper part of the tower 202.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com