Method for separating each component ore in pyrite-ion adsorption type rare earth complex ore

An ion-adsorption type and rare earth compounding technology, which is applied in the direction of wet separation, solid separation, chemical instruments and methods, etc., can solve the problem that the ion-adsorption type rare earth resources have not been utilized, and achieve easy solid-liquid separation, broaden the scope of application, Good economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

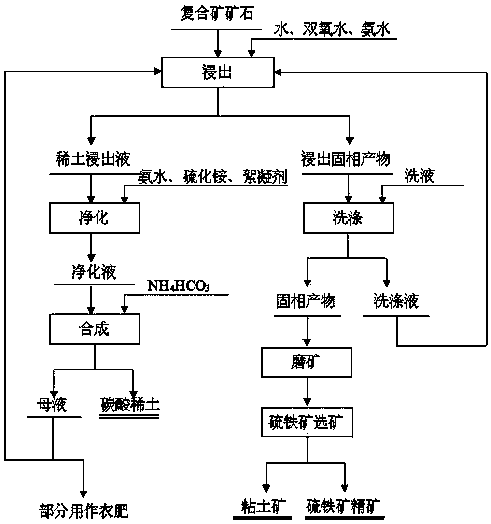

Image

Examples

Embodiment 1

[0034] The ion adsorption type rare earth-pyrite compound ore extracts rare earth, reclaims the method for pyrite and clay ore, and its steps are as follows:

[0035] (1) Grinding the raw ore to -80 mesh ore accounts for 30.2% of the raw ore mass percentage. The detected ore TREO content is 1209×10 -6 , S content is 12.20%, Al 2 o 3 The content is 23.41%, SiO 2 The content is 29.52%. Ion-adsorbed rare earths in ores accounted for 56.4% of the total rare earths.

[0036] (2) Add 5.0kg of finely crushed ore into 4kg of water, add 30ml of hydrogen peroxide, stir for 30min, slowly add 0.45L of ammonia water (20ml / min) at room temperature (25°C), adjust the pH of the solution to 4.0, and continue stirring for 40min , separate the slurry from solid to liquid to obtain 3.17 liters of rare earth leachate (NH 4 + 2.51 / L, TREO content is 825mg / L, Al content is 1410mg / L, Fe content is 390mg / L, Pb content is 1.4mg / L); the filter cake is washed with 2.50 liters of water (NH 4 + ...

Embodiment 2

[0041] The ion adsorption type rare earth-pyrite compound ore extracts rare earth, reclaims the method for pyrite and clay ore, and its steps are as follows:

[0042] (1) Grinding the raw ore to -80 mesh ore accounts for 59% of the raw ore mass percentage. The original ore TREO content is 755×10 -6 , S content is 13.72%, Al 2 o 3 Content 22.61%, SiO 2 The content is 28.73%. Ion-adsorbed rare earths accounted for 43.30% of the total rare earths in the ore.

[0043] (2) Add 5.0kg of finely crushed ore to 4.0kg of aqueous solution, add 35ml of hydrogen peroxide, and stir at room temperature (28°C) for 30 minutes; slowly add 0.7 liters of ammonia water (30ml / min) to adjust the pH of the solution to 4.6, and stir for 40 minutes Finally, add 8 mL of flocculant, continue to stir for 10 min, put the slurry into a vacuum filter tank for suction filtration, and wash with 1.7 liters of water (NH 4 + 3.0g / L, pH value 4.5) to wash the filter cake, and the washing liquid and the soa...

Embodiment 3

[0048] The ion adsorption type rare earth-pyrite compound ore extracts rare earth, reclaims the method for pyrite and clay ore, and its steps are as follows:

[0049] (1) Crushing and finely crushing the raw ore until the particle size is -80 mesh and the weight of the ore particles accounts for 49.5% of the weight of the raw ore. The detected ore TREO content is 552×10 -6 , S content is 12.70%, Al 2 o 3 The content is 25.81%, SiO 2 The content is 31.62%. Ion-adsorbed rare earths accounted for 41.69% of the total rare earths in the ore.

[0050] (2) Add 5.0kg of finely crushed ore into 4kg of water, add 40ml of hydrogen peroxide, and stir at room temperature (28°C) for 50min. Slowly add 0.70 liters of ammonia water (20ml / min), adjust the pH value of the solution to 4.5, and continue to stir for 20 minutes; add 7ml of flocculant, and stir for 8 minutes; after the solid-liquid separation of the slurry, wash with 1.80 liters of water (NH 4 + 3.5g / L, pH value 4.5) to wash ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com