Separation method of each component ore in pyrite-ion adsorption type rare earth composite ore

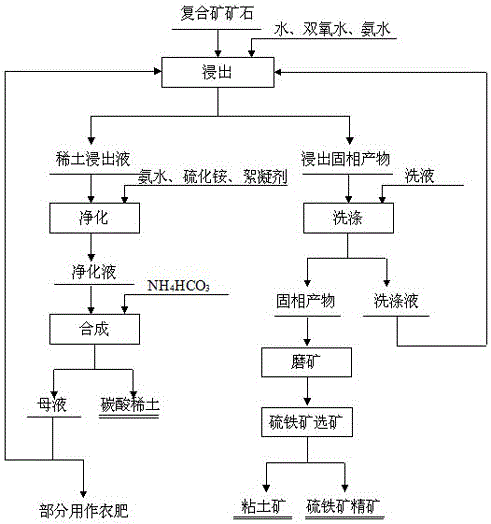

An ion adsorption type, rare earth composite technology, applied in wet separation, solid separation, chemical instruments and methods, etc., can solve the problem that ion adsorption type rare earth resources have not been utilized yet, achieve easy solid-liquid separation, low power consumption, The effect of broadening the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The ion adsorption type rare earth-pyrite compound ore extracts rare earth, reclaims the method for pyrite and clay ore, and its steps are as follows:

[0035] (1) Grinding the raw ore to -80 mesh ore accounts for 30.2% of the raw ore mass percentage. The detected ore TREO content is 1209×10 -6 , S content is 12.20%, Al 2 o 3 The content is 23.41%, SiO 2 The content is 29.52%. Ion-adsorbed rare earths in ores accounted for 56.4% of the total rare earths.

[0036] (2) Add 5.0kg of finely crushed ore into 4kg of water, add 30ml of hydrogen peroxide, stir for 30min, slowly add 0.45L of ammonia water (20ml / min) at room temperature (25°C), adjust the pH of the solution to 4.0, and continue stirring for 40min , separate the slurry from solid to liquid to obtain 3.17 liters of rare earth leachate (NH 4 + 2.51 / L, TREO content is 825mg / L, Al content is 1410mg / L, Fe content is 390mg / L, Pb content is 1.4mg / L); the filter cake is washed with 2.50 liters of water (NH 4 + 3....

Embodiment 2

[0041] The ion adsorption type rare earth-pyrite compound ore extracts rare earth, reclaims the method for pyrite and clay ore, and its steps are as follows:

[0042] (1) Grinding the raw ore to -80 mesh ore accounts for 59% of the raw ore mass percentage. The original ore TREO content is 755×10 -6 , S content is 13.72%, Al 2 o 3 Content 22.61%, SiO 2 The content is 28.73%. Ion-adsorbed rare earths accounted for 43.30% of the total rare earths in the ore.

[0043] (2) Add 5.0kg of finely crushed ore to 4.0kg of aqueous solution, add 35ml of hydrogen peroxide, and stir at room temperature (28°C) for 30 minutes; slowly add 0.7 liters of ammonia water (30ml / min) to adjust the pH of the solution to 4.6, and stir for 40 minutes Finally, add 8 mL of flocculant, continue to stir for 10 min, put the slurry into a vacuum filter tank for suction filtration, and wash with 1.7 liters of water (NH 4 + 3.0g / L, pH value 4.5) to wash the filter cake, and the washing liquid and the soak...

Embodiment 3

[0048] The ion adsorption type rare earth-pyrite compound ore extracts rare earth, reclaims the method for pyrite and clay ore, and its steps are as follows:

[0049] (1) Crushing and finely crushing the raw ore until the particle size is -80 mesh and the weight of the ore particles accounts for 49.5% of the weight of the raw ore. The detected ore TREO content is 552×10 -6 , S content is 12.70%, Al 2 o 3 The content is 25.81%, SiO 2 The content is 31.62%. Ion-adsorbed rare earths accounted for 41.69% of the total rare earths in the ore.

[0050] (2) Add 5.0kg of finely crushed ore into 4kg of water, add 40ml of hydrogen peroxide, and stir at room temperature (28°C) for 50min. Slowly add 0.70 liters of ammonia water (20ml / min), adjust the pH value of the solution to 4.5, and continue to stir for 20 minutes; add 7ml of flocculant, and stir for 8 minutes; after the solid-liquid separation of the slurry, wash with 1.80 liters of water (NH 4 + 3.5g / L, pH value 4.5) to wash t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com