Producer gas desulphurization process

A producer gas and desulfurization process technology, applied in the petroleum industry, combustible gas purification, combustible gas purification/transformation, etc., can solve the problems of low desulfurization efficiency, seriousness, backward technology, etc., and achieve high sulfur recovery rate and no sulfur plugging Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

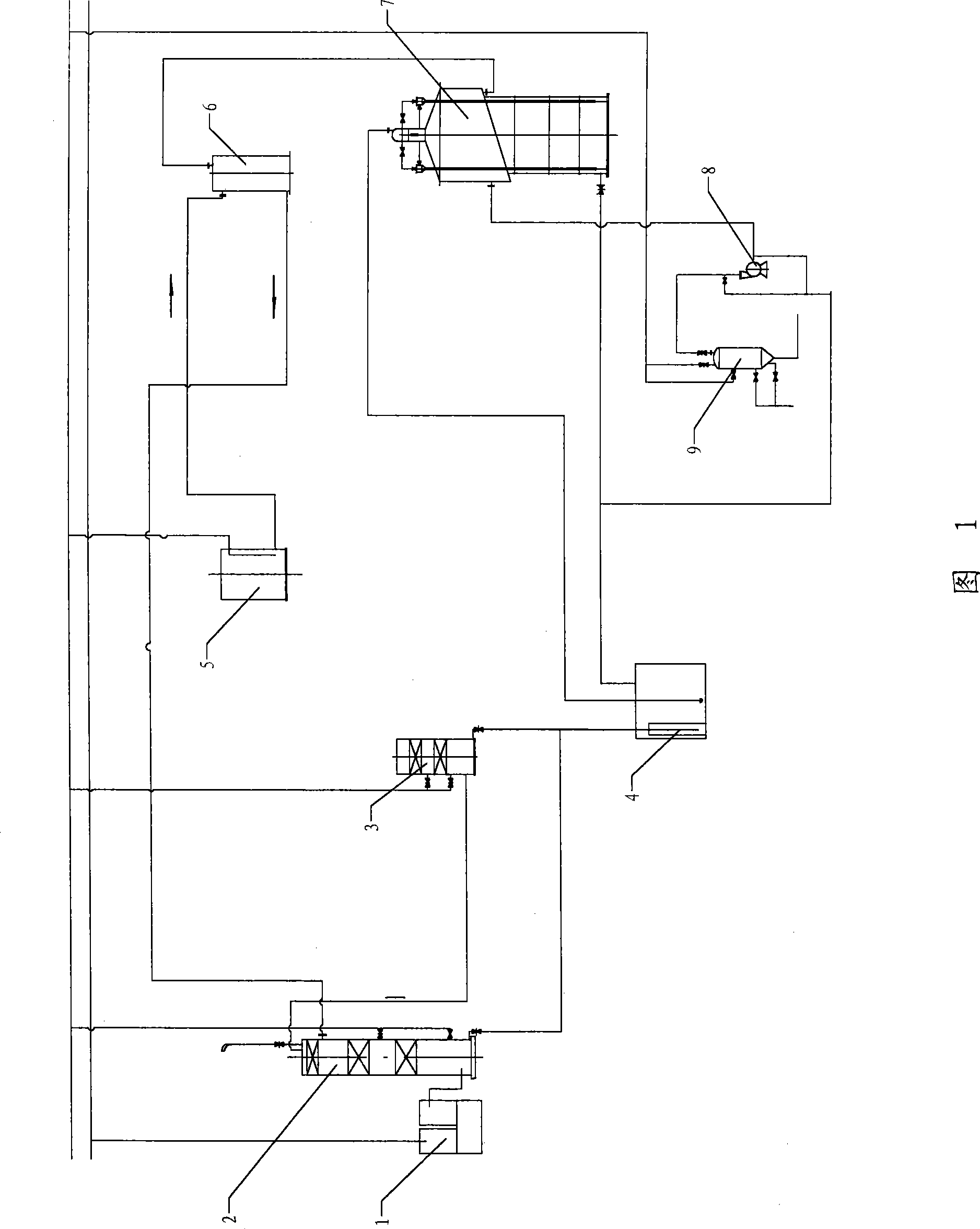

[0041] Sulfur content from coal gasifier is 2000mg / Nm 3 After being filtered by the water seal 1, the gas enters the lower part of the desulfurization tower 2 at 30-45°C and 35KPa, and the gas intake speed is 3000mg / Nm 3 , after countercurrent contact with the desulfurization liquid sprayed on the top of the tower, it becomes tower gas; the absorbed desulfurization rich liquid is discharged from the bottom of the tower and enters the rich liquid tank 4; the desulfurized rich liquid is sprayed into the regeneration tank 7 and mixed with air for regeneration, The regenerated desulfurized liquid is sent to the desulfurization tower 2 through the lean liquid tank 7. Because of the consumption of soda ash in the absorption process, before entering the desulfurization tower, a quantitative soda ash solution is added from the alkali liquid tank 5 to the lean liquid tank 6; from the regeneration tank 7. The sulfur-containing foam that floats out is pumped into the sulfur-melting kettl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com