Biogas desulfurization method in series of wet method with dry method

A biogas desulfurization and dry desulfurization technology, which is applied in the direction of gas fuel, petroleum industry, fuel, etc., can solve the problems of high operation and maintenance costs, poor purification accuracy, and inability to remove, so as to achieve stable treatment effect, eliminate environmental problems, The effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

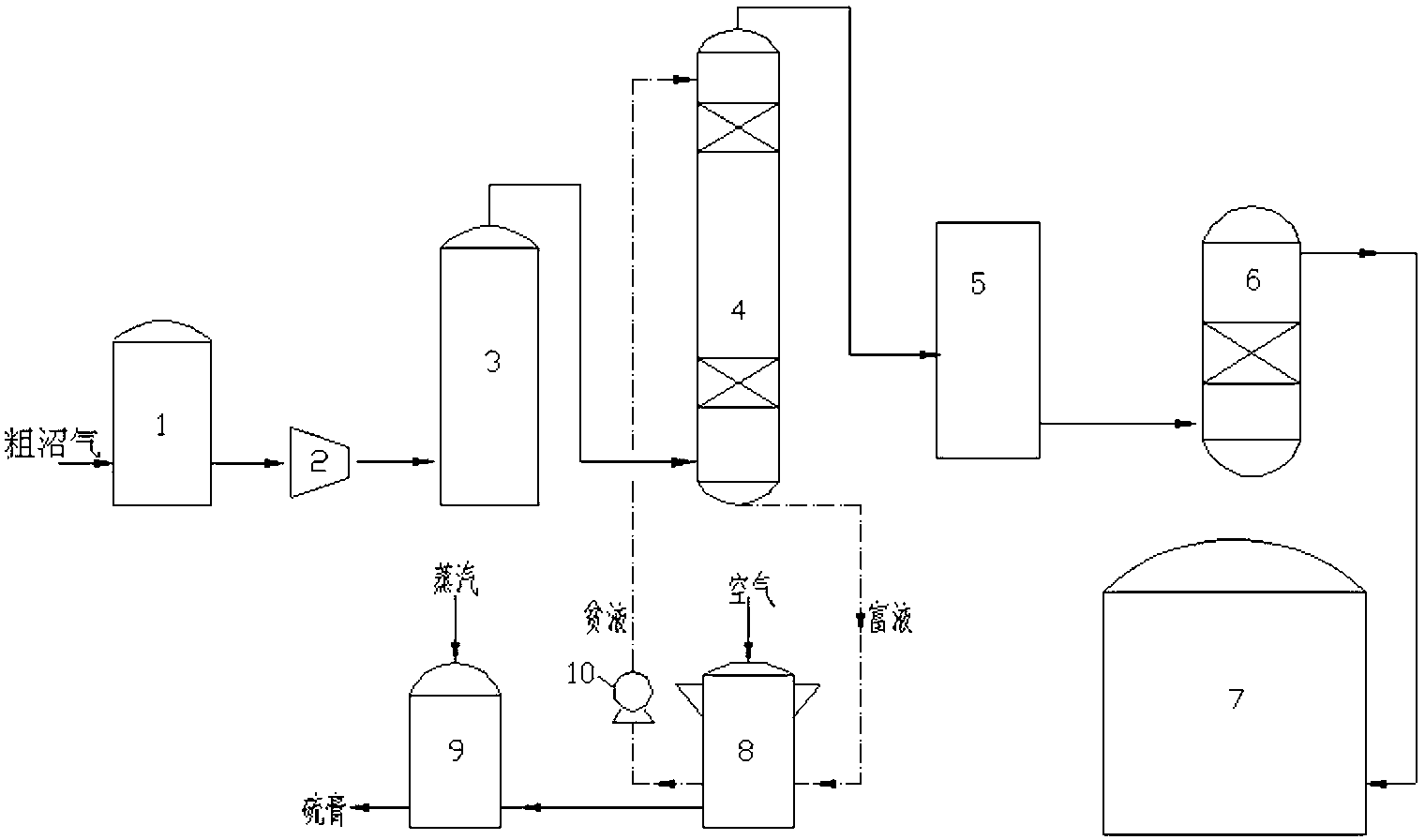

[0014] Example: such as figure 1 A kind of biogas desulfurization method in which the wet method and the dry method are connected in series is shown, and the specific steps are as follows:

[0015] Raw biogas (H 2 The S content is about 800~2200mg / Nm3) enters the buffer tank 1 (pressure 3~5kpa), is boosted by the biogas pressurization fan 2 to 10.0Mpa, then enters the water washing tower 3, reduces the biogas temperature to 25~30℃, and then enters Wet desulfurization tower 4, in which the crude biogas is in countercurrent contact with the desulfurization solution and the catalyst to remove most impurities such as hydrogen sulfide, and the desulfurization solution uses NaCO 3 solution, the concentration was maintained at NaCO 3 The solution is 2-3g / l, the catalyst is 4ppm; then the biogas enters the dehydration tower 5 to separate the water, and then enters the dry desulfurization tower 6. The dry desulfurization uses an amorphous iron oxyhydroxide desulfurizer to further rem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com