Filling method for sulfur recycled catalyst with high content of CO2 in raw material gas to be treated

A sulfur recovery and catalyst technology, applied in chemical recovery, sulfur preparation/purification, etc., can solve problems such as high wear, poor organic sulfur hydrolysis ability, and poor strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

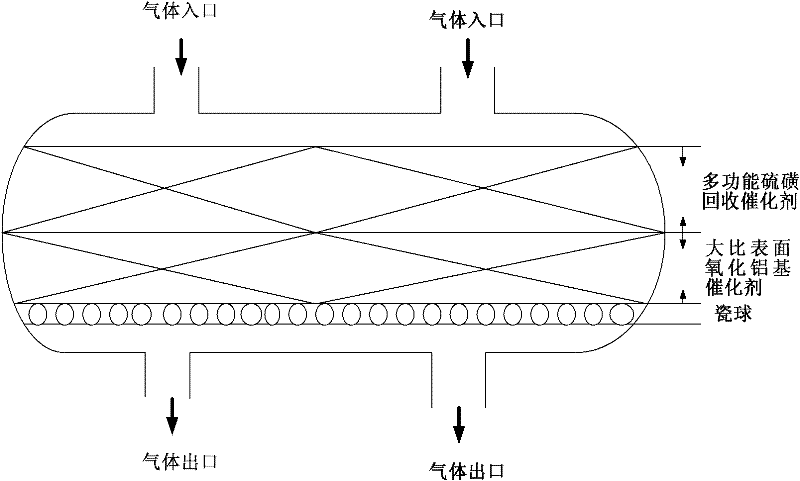

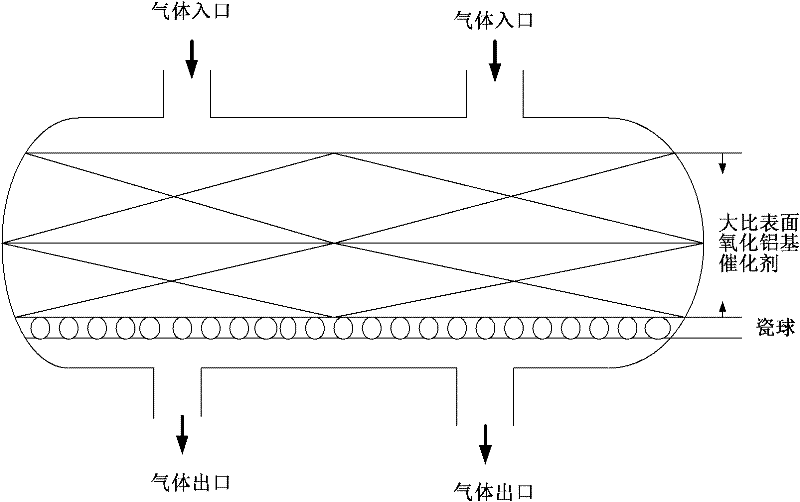

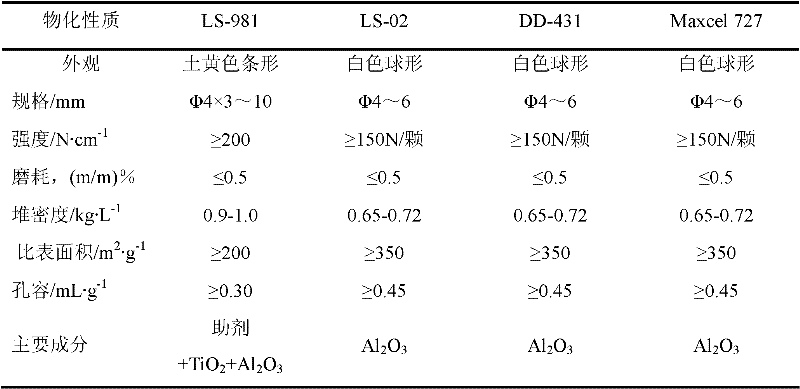

[0038] The present invention is applied to a certain 80,000 tons / year sulfur recovery device, and the CO in the feed gas of the device 2 The gas volume content is 40% to 50%, which is much higher than the normal sulfur recovery device. The two-stage sulfur production reactors are filled with sulfur production catalysts respectively. The catalyst loading method is as follows: Lay two layers of 8-mesh stainless steel wire mesh on the bottom of the primary converter, and fill the upper part of the stainless steel wire mesh with a height of 120mm. Five-hole hard ceramic balls; refill the LS-02 alumina-based sulfur recovery catalyst with a bed height of 400mm, a total of 14t; refill the LS-981 multifunctional sulfur recovery catalyst with a height of about 400mm, a total of 20t, see details figure 1 . The secondary converter catalysts are all filled with LS-02 alumina-based sulfur recovery catalysts with large specific surface area. The filling method of the stainless steel wire...

Embodiment 2

[0040] The present invention is applied to a certain 80,000 tons / year sulfur recovery device, and the CO in the feed gas of the device 2 The gas volume content is 10% to 20%, which is higher than the normal sulfur recovery device. The two-stage sulfur production reactors are filled with sulfur production catalysts. The catalyst loading method is as follows: Lay two layers of 8-mesh stainless steel wires at the bottom of the primary converter Mesh, stainless steel wire mesh upper filling height 120mm Five-hole hard ceramic balls; reload LS-02 alumina-based sulfur recovery catalyst with a bed height of 560mm, a total of 20t; refill LS-981 multifunctional sulfur recovery catalyst with a height of about 240mm, a total of 12t, see details figure 1 . The secondary converter catalysts are all filled with LS-02 alumina-based sulfur recovery catalysts with large specific surface area. The filling method of the stainless steel wire mesh and five-hole hard ceramic balls is the same as...

Embodiment 3

[0042] The present invention is applied to a certain 80,000 tons / year sulfur recovery device, and the CO in the feed gas of the device 2 The gas volume content is 40% to 50%, which is much higher than the normal sulfur recovery device. The two-stage sulfur production reactors are filled with sulfur production catalysts. The catalyst loading method is as follows: Lay two layers of 8-mesh stainless steel at the bottom of the primary converter Wire mesh, stainless steel wire mesh upper filling height of 120mm Five-hole hard ceramic balls; reload DD-431 alumina-based sulfur recovery catalyst with a bed height of 400mm, a total of 14t; refill LS-981 multifunctional sulfur recovery catalyst with a height of about 400mm, a total of 20t, see details figure 1 . The secondary converter catalysts are all filled with DD-431 large specific surface area alumina-based sulfur recovery catalysts. The filling method of the stainless steel wire mesh and five-hole hard ceramic balls is the sam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com