Complexing iron desulfurizing agent for Claus tail gas treatment

A technology of Claus tail gas and complex iron, which is applied in gas treatment, membrane technology, and separation of dispersed particles, can solve problems such as the inability to remove carbonyl sulfide, and achieve significant economic and social benefits, high activity, and improved Effect of Total Sulfur Recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

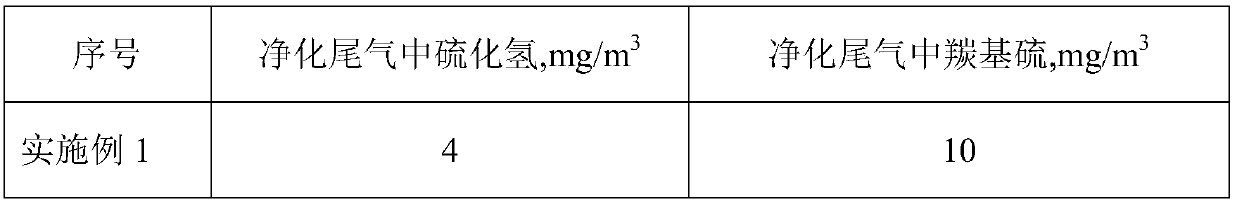

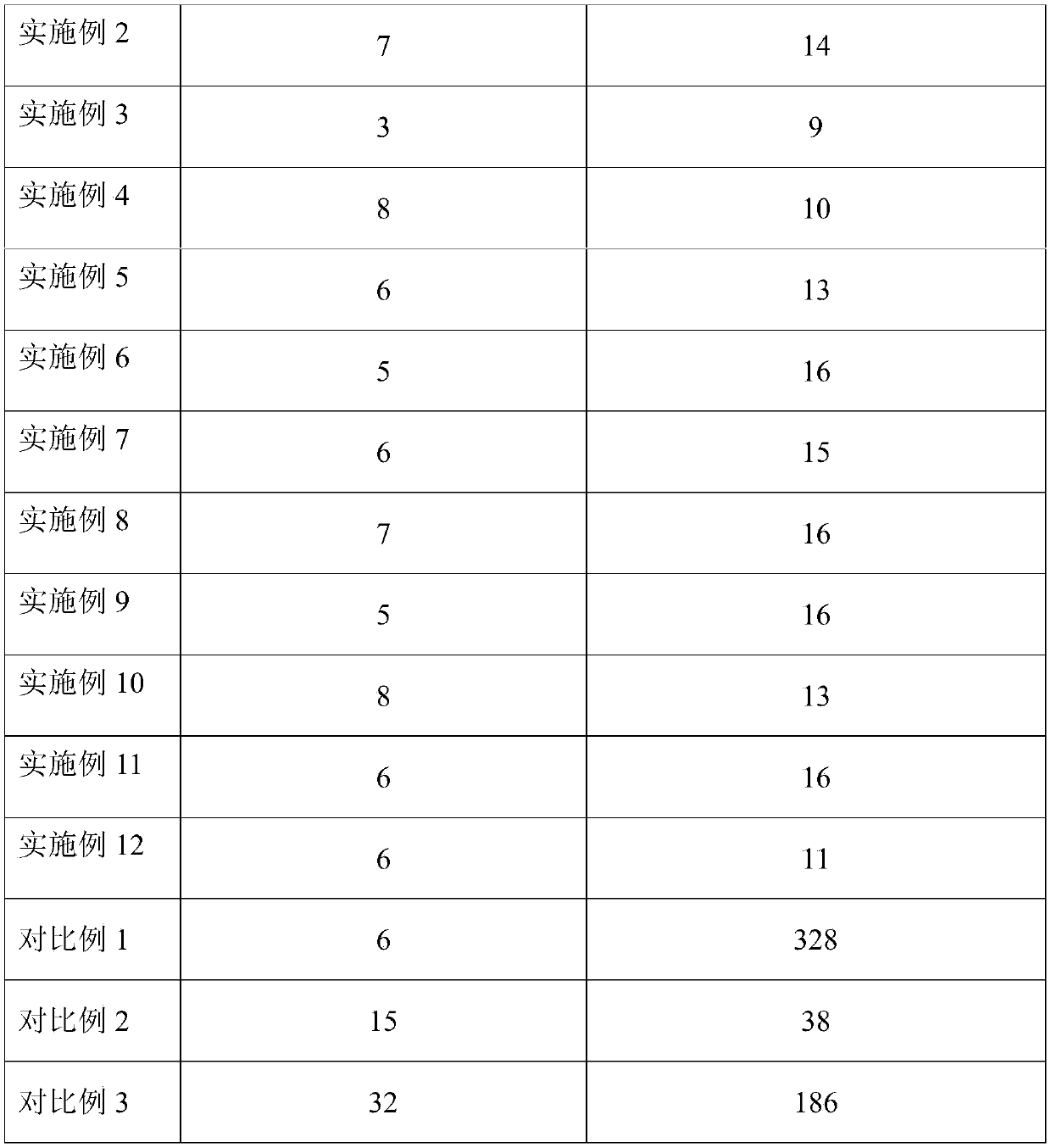

Examples

Embodiment 1

[0024] A complex iron desulfurizer for treating Claus tail gas, comprising the following components: soluble iron salt, soluble cerium salt, chelating agent, inorganic base, organic additive and water.

[0025] With ferric citrate, Fe(NH 4 ) 2 (SO 4 ) 2 ·6H 2 O is used as a soluble iron salt, cerium sulfate is used as a soluble cerium salt, EDTA is used as a chelating agent, p-benzoquinone is used as an organic additive, and sodium carbonate is used as an inorganic base to prepare a desulfurization solvent. The contents of each component are as follows:

[0026] Iron ions: 4.5%wt, of which Fe 3+ with Fe 2+ The molar ratio of Ce is 3; Ce 3+ : 0.25%wt; the molar ratio of sodium ion to iron ion is 0.8; the molar ratio of EDTA to the sum of iron ion and cerium ion is 2.0; the content of p-benzoquinone is 1.0wt%, and the rest is water.

[0027] The desulfurizer is used to treat Claus tail gas in complex iron desulfurization unit.

Embodiment 2

[0029] A complex iron desulfurizer for treating Claus tail gas, comprising the following components: soluble iron salt, soluble cerium salt, chelating agent, inorganic base, organic additive and water.

[0030] With ferric citrate, Fe(NH 4 ) 2 (SO 4 ) 2 ·6H 2 O is used as a soluble iron salt, cerium sulfate is used as a soluble cerium salt, EDTA is used as a chelating agent, p-benzoquinone is used as an organic additive, and sodium carbonate is used as an inorganic base to prepare a desulfurization solvent. The contents of each component are as follows:

[0031] Iron ions: 0.5%wt, where Fe 3+ with Fe 2+ The molar ratio of Ce is 0.5; Ce3+ : 0.1%wt; the molar ratio of sodium ion to iron ion is 0.5; the molar ratio of EDTA to the sum of iron ion and cerium ion is 1.0; the content of p-benzoquinone is 0.2wt%, and the rest is water.

[0032] The desulfurizer is used to treat Claus tail gas in complex iron desulfurization unit.

Embodiment 3

[0034] A complex iron desulfurizer for treating Claus tail gas, comprising the following components: soluble iron salt, soluble cerium salt, chelating agent, inorganic base, organic additive and water.

[0035] With ferric citrate, Fe(NH 4 ) 2 (SO 4 ) 2 ·6H 2 O is used as a soluble iron salt, cerium sulfate is used as a soluble cerium salt, EDTA is used as a chelating agent, p-benzoquinone is used as an organic additive, and sodium carbonate is used as an inorganic base to prepare a desulfurization solvent. The contents of each component are as follows:

[0036] Iron ions: 5.0%wt, where Fe 3+ with Fe 2+ The molar ratio of Ce is 5.0; Ce 3+ : 0.5%wt; the molar ratio of sodium ion to iron ion is 1.0; the molar ratio of EDTA to the sum of iron ion and cerium ion is 3.5; the content of p-benzoquinone is 2wt%, and the rest is water.

[0037] The desulfurizer is used to treat Claus tail gas in complex iron desulfurization unit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com