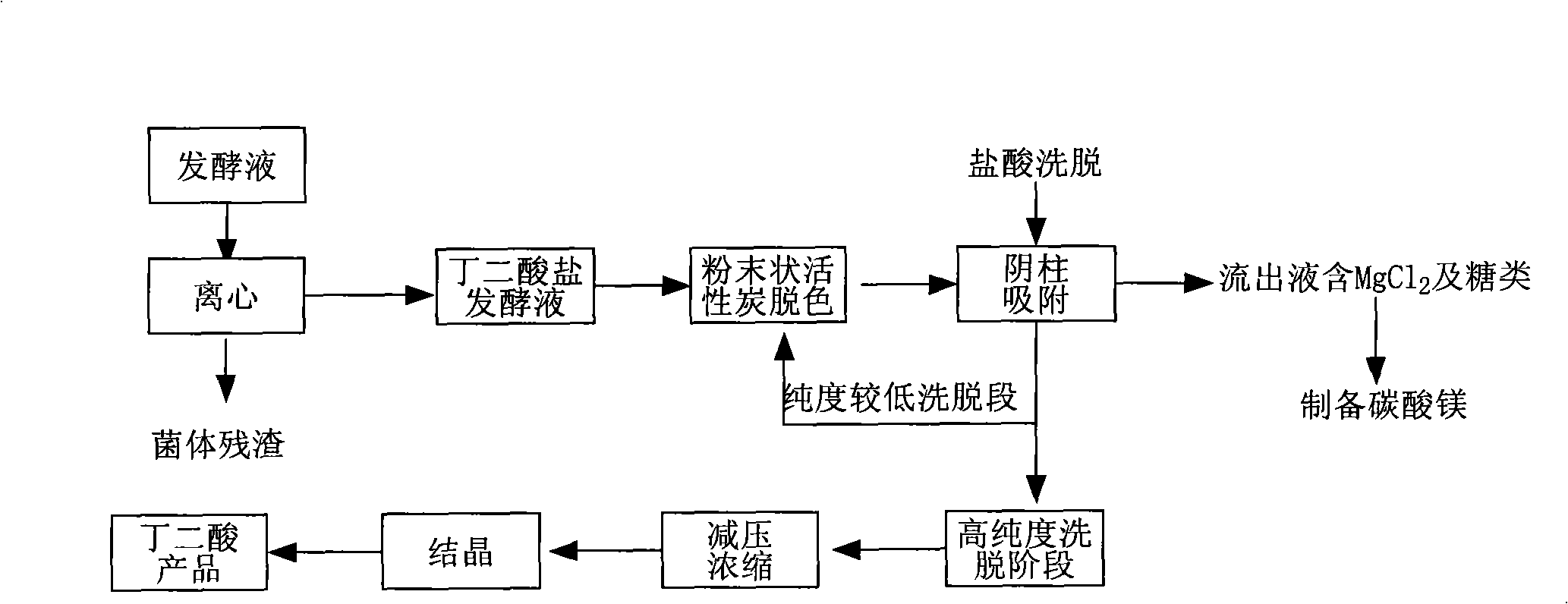

Method for extracting amber acid in fermentation liquor by anion resin adsorption

An anion resin, adsorption and extraction technology, applied in the direction of fermentation, ammonium sulfate, separation/purification of carboxylic acid compounds, etc., to achieve the effects of shortening the process flow, improving product economic benefits, and reducing environmental protection treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Experimental conditions: The fermentation broth used in this experiment was fermented with corn syrup as raw material, and MgCO was used in the fermentation process 3 Adjust pH.

[0031] The above-mentioned fermentation liquid was heated to 80° C., and after adding 0.1% powdered activated carbon by weight of the fermentation liquid for decolorization, the bacteria residue was removed by centrifugation at 8000 r / min for 10 min to obtain the fermentation supernatant.

[0032] The resin used is shown in Table 1. At 25°C, add 2g of wet resin and 20mL of 40g / L succinic acid fermentation broth into a 250mL Erlenmeyer flask, place the Erlenmeyer flask in a constant temperature shaker, and exchange it at 200r / min for 24h. When the concentration of succinic acid does not change any more, it means that the resin has reached separation saturation. Then measure the concentration of succinic acid in the solution, and calculate the ion exchange capacity of succinic acid by subtracti...

Embodiment 2

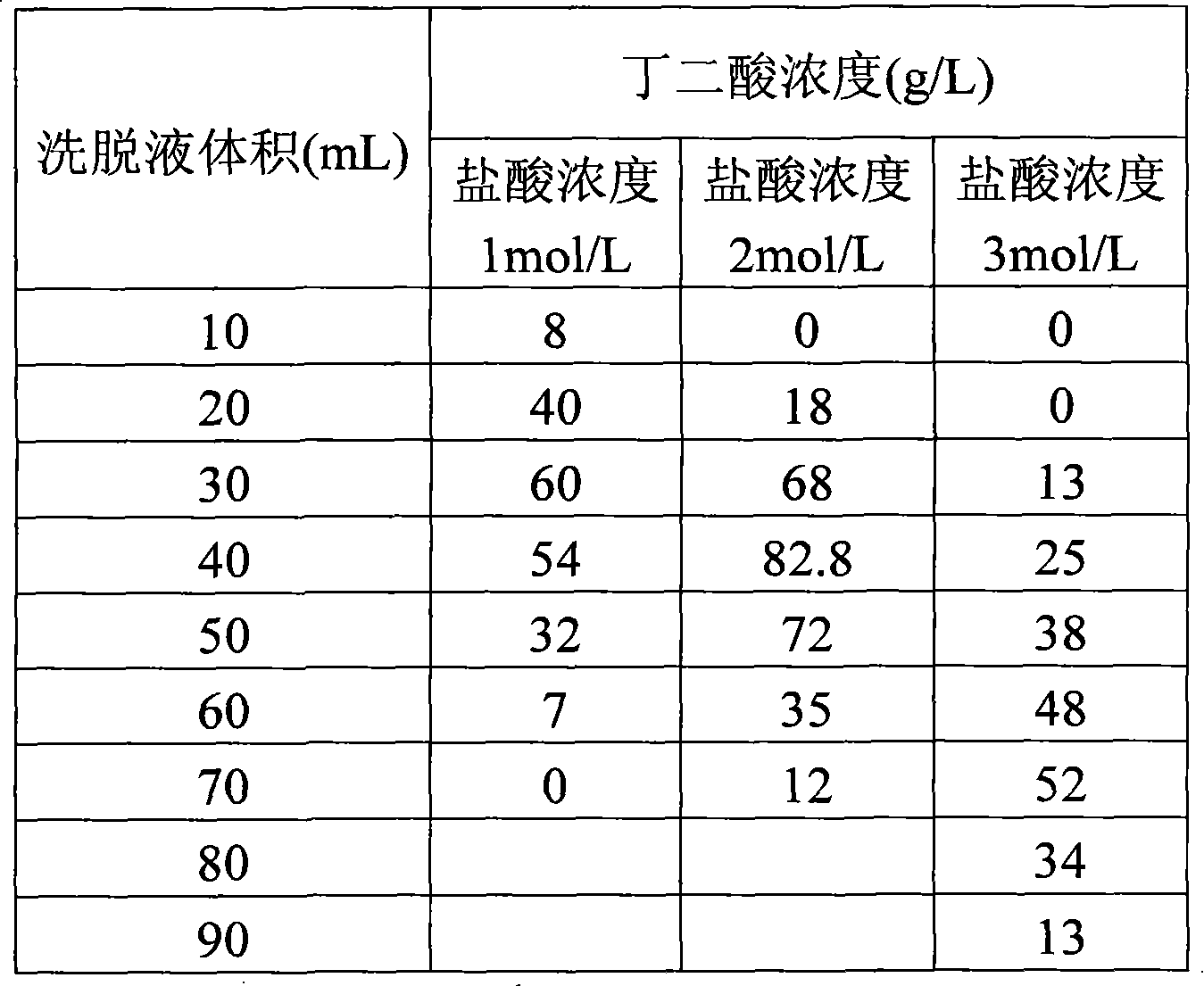

[0038] The above-mentioned magnesium succinate fermentation supernatant was put on the column for adsorption, and the flow rate of the upper column was 2.9h -1. Then wash away impurities with water 1 to 2 times the weight of the fermentation broth, elute with 1mol / L, 2mol / L, and 3mol / L hydrochloric acid, respectively, at a flow rate of 1.8h -1 、2.9h -1 、4.5h -1 elute down. Its experimental result is as table 3 (elution flow rate 1.8h -1 Different hydrochloric acid concentrations to the elution result of anion exchange resin adsorption succinic acid) and Table 4 (hydrochloric acid concentration 2mol / L different elution flow rates to anion exchange resin adsorption succinic acid elution result).

[0039] table 3

[0040]

[0041] The results in the above table show that the elution flow rate is 1.8h -1 When using 2mol / L hydrochloric acid elution effect is better.

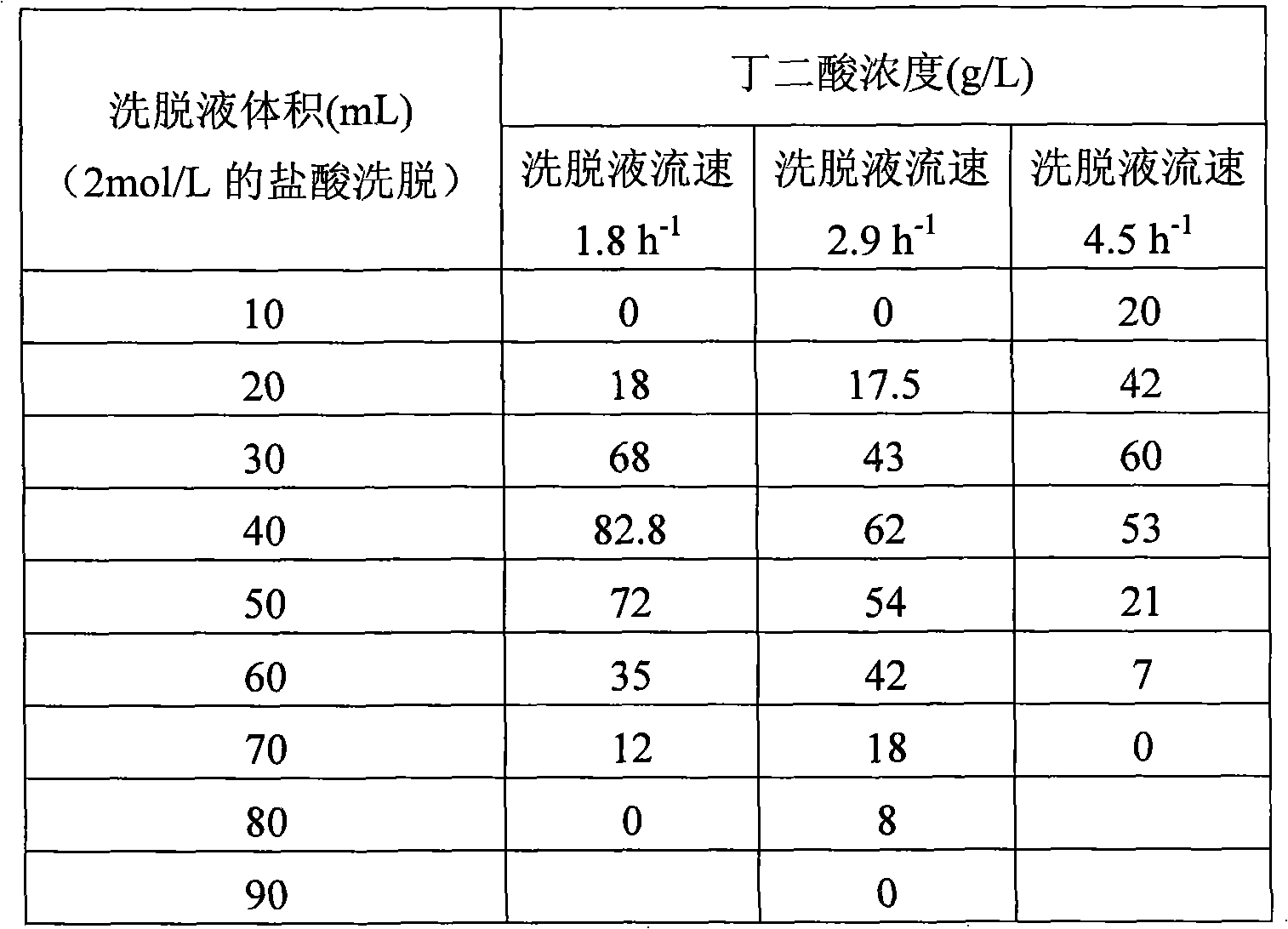

[0042] Table 4

[0043]

[0044] It can be seen from the above table that the elution flow rate is co...

Embodiment 3-8

[0046] Adopt the process condition of embodiment 1 and embodiment 2, respectively with corn starch hydrolysis syrup, tapioca starch hydrolysis syrup, industrial sugar waste molasses (such as sugarcane molasses), corn stalk hydrolysis syrup, Jerusalem artichoke hydrolysis syrup, sweet sorghum stalk syrup Extract the fermentation broth as the raw material, and finally concentrate and crystallize the eluate to obtain the succinic acid product, use MgCO 3 When the pH of the fermentation process is adjusted by buffering, the effluent from the column can be prepared by the ammonium brine bicarbonate method to prepare magnesium carbonate, which is recovered and used to adjust the pH of the fermentation process.

[0047] The yields of each step of extracting succinic acid in various raw material fermentation broths by anion resin adsorption are shown in Table 5.

[0048] table 5

[0049]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com