Synchronous denitration process based on wet ammonia process flue gas desulfurization

An ammonia desulfurization and flue gas technology, applied in the field of flue gas purification, can solve the problems of inability to be industrially practical, uneconomical complexing agents, and high prices, so as to reduce equipment investment and operating costs, reduce procurement costs, and reduce energy. consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

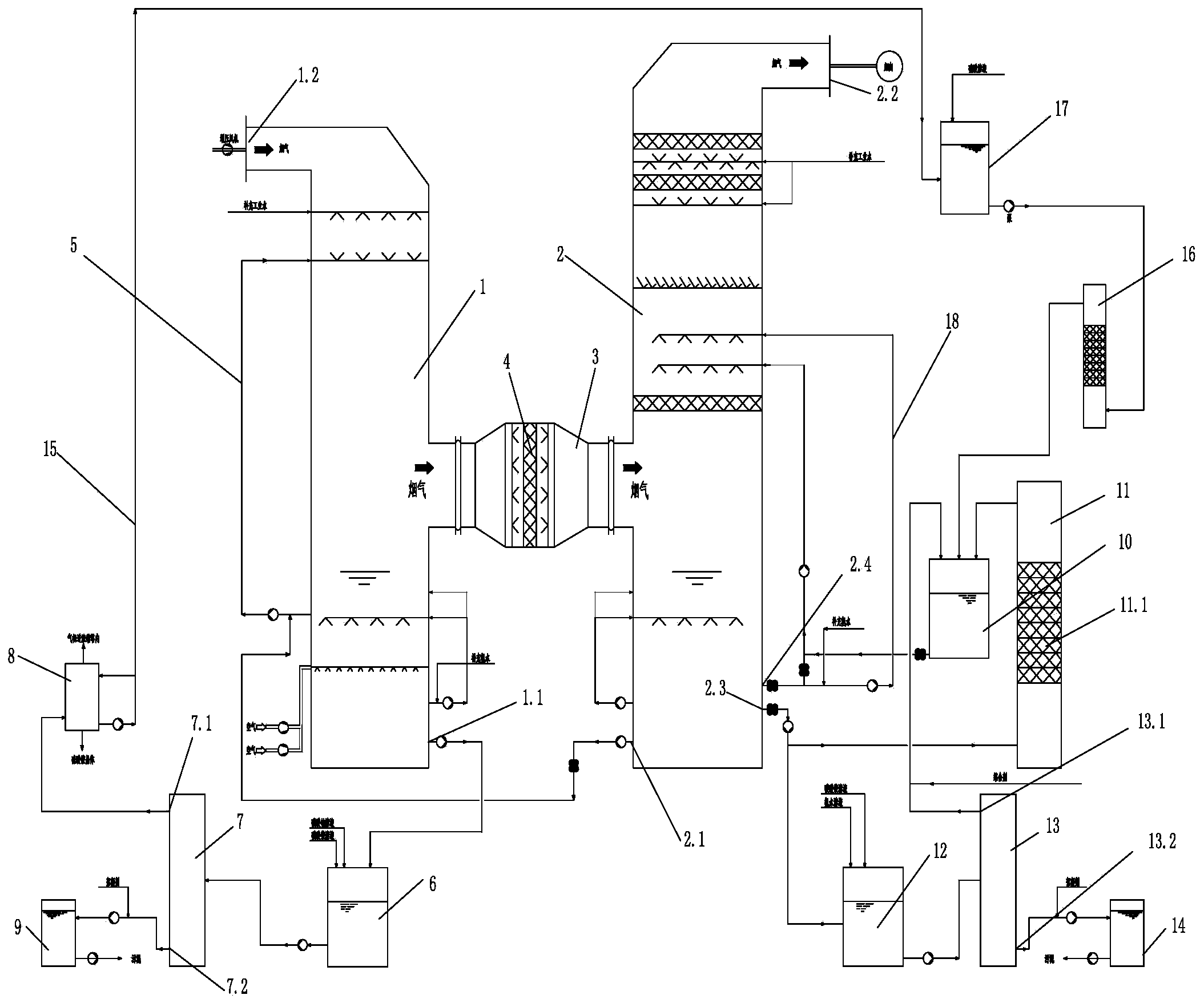

[0050] System embodiment:

[0051] The middle section of the concentration tower 1 is connected to the middle section of the absorption tower 2 through the flue gas pipeline 3 provided with a wire mesh filter 4, the top of the concentration tower 1 is provided with a flue gas inlet 1.2, and the top of the absorption tower 2 is provided with a flue gas outlet 2.2 . The drainage port 2.1 at the bottom of the absorption tower 2 is connected to the concentrated liquid circulation spray line 5 of the concentration tower 1 through a pipe. The drain port 1.1 of the concentration tower 1 is connected with the first sedimentation tank 7 through the first iron removal reaction tank 6, and the clear liquid outlet 7.1 of the upper section of the first sedimentation tank 7 is connected with the ammonium sulfate crystallization system 8, and the slurry of the lower section The outlet 7.2 is connected to the first concentration tank 6, the ammonium sulfate crystallization system 8 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com