Coke oven flue gas desulfurization, denitration and waste heat recovery integrated method

A waste heat recovery and waste heat recovery device technology, applied in chemical instruments and methods, separation methods, chemical industry, etc., can solve the problems of low desulfurization, denitrification efficiency, and inability to meet the optimal temperature for desulfurization, so as to reduce costs and reduce operation Cost, the effect of simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

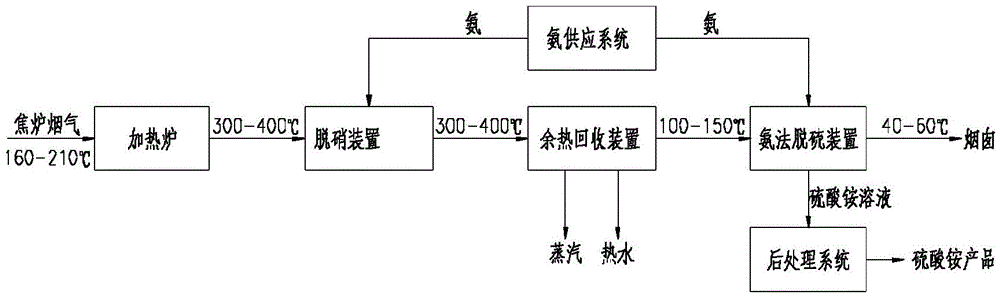

[0021] 1. The flue gas temperature from the coke oven is about 100-210℃, and the sulfur dioxide content is 100-3500mg / Nm 3 , the content of nitrogen oxides is 100-1500mg / Nm 3 . The flue gas first enters the heating furnace and heats up to 300-400°C. This temperature is most conducive to denitrification to achieve a higher denitrification efficiency.

[0022] 2. The flue gas from the heating furnace enters the flue gas denitration device, and the 300-400 ℃ flue gas from the heating furnace enters the denitrification device to remove nitrogen oxides. The flue gas denitrification device uses ammonia as a reducing agent to remove nitrogen in the flue gas oxides, the denitrification efficiency can reach 83-90%. Ammonia comes from the ammonia supply system.

[0023] 3. The flue gas temperature from the flue gas denitrification device is still 300-400°C, and the flue gas has a lot of residual heat, which enters the waste heat recovery device (waste heat boiler) to recover the heat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| denitrification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com