Electrolytic manganese slag comprehensive utilization technique

An electrolytic manganese slag and process technology, applied in the field of electrolytic manganese slag treatment, can solve the problems of insufficient utilization of electrolytic manganese resources, high cost of site occupation, low production efficiency, etc., and achieve the elimination of water pollution sources, great social and economic benefits, The effect of solving pollution

Inactive Publication Date: 2008-11-19

卿富安

View PDF4 Cites 31 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

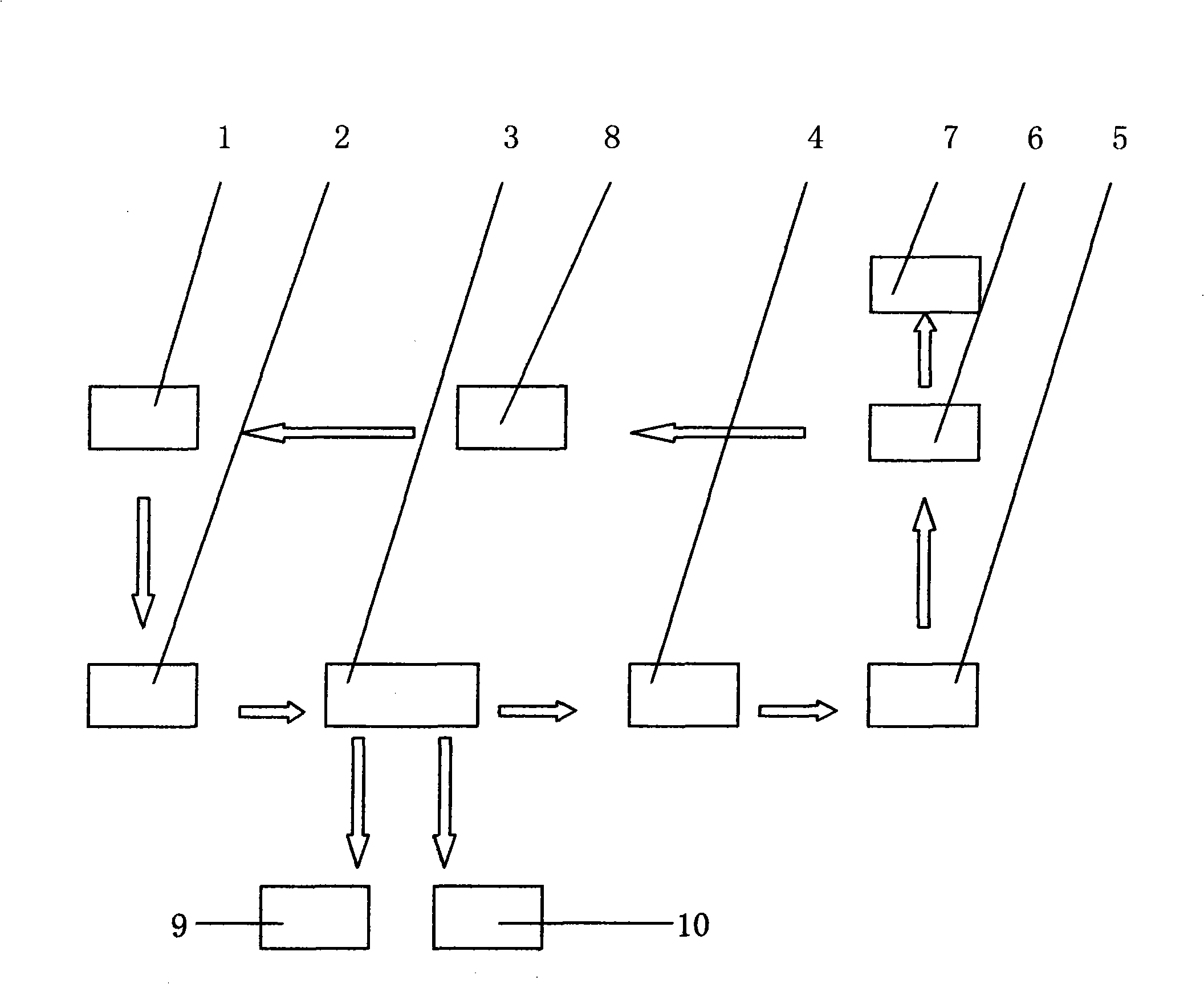

The present invention is aimed at the above technical problems, and provides a simple process, low cost, zero pollution discharge, and can solve the problems of insufficient resource utilization, low production efficiency, serious environmental pollution, and high site occupation costs in current electrolytic manganese production enterprises. Process of Comprehensive Utilization of Electrolytic Manganese Slag

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to an electrolytic manganese slag processing method, in particular to an electrolytic manganese slag comprehensive utilization process. The method recovers the recyclable materials in electrolytic manganese slag through repeated water washing and filtering. The method can solve the air pollution source, particularly eliminate the water pollution source, and protect people health from being damaged. The method can extract higher-value chemical products through the scientific flow, and make the residuary filter residue into building products, thereby effectively utilizing the resource. Zero discharge is realized during the overall process of the technical proposal of the method, and because no additional chemical substances are added, additional environmental pollution can not be caused.

Description

A process for comprehensive utilization of electrolytic manganese slag technical field The invention relates to a treatment method for electrolytic manganese slag, in particular to a process for comprehensive utilization of electrolytic manganese slag. Background technique In the process of producing metal manganese, the electrolytic manganese plant will discharge a large amount of solid waste - manganese slag. Manganese slag not only occupies a large amount of land and devours good fields, but also the harmful gas emitted by manganese slag directly affects the health of nearby people, which is even more serious The most important thing is: the liquid seeping from the manganese slag slowly soaks into the ground to pollute the water quality, and the harmful substances include a variety of heavy metals and excessive ammonia nitrogen. At the same time, there is a considerable amount of available manganese, nickel, nitrogen, etc. in the electrolytic manganese slag. The curren...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B09B3/00C04B33/138C04B18/14C04B7/147C01C1/24

CPCY02P40/10Y02P40/60Y02W30/91

Inventor 卿富安

Owner 卿富安

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com