Cleaning treatment method of dying industrial acidic wastewater

A technology of acid wastewater and dyes, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve problems such as secondary pollution, high cost, hidden safety hazards, etc., and achieve clean production , solve disposal problems, and increase production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

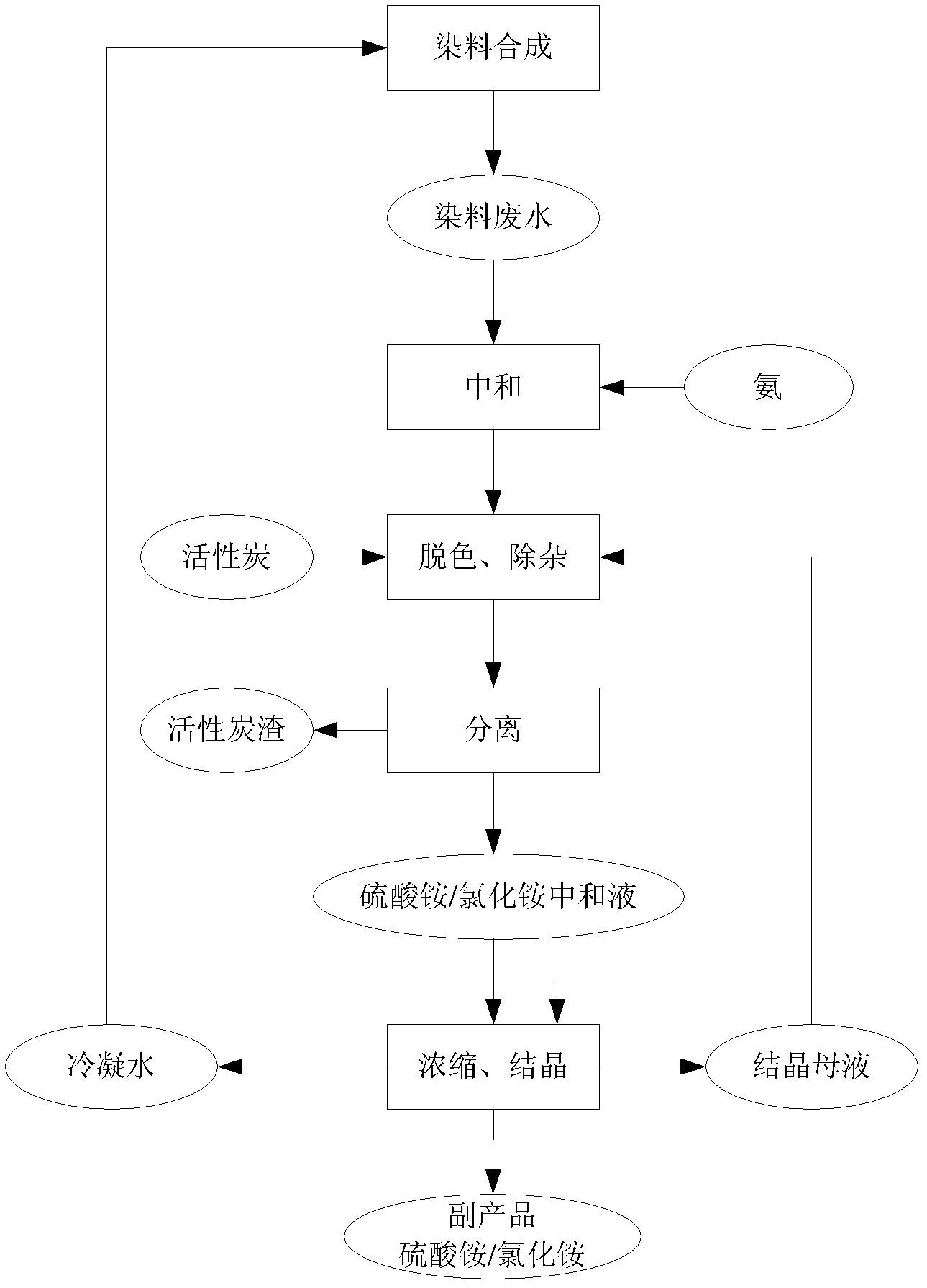

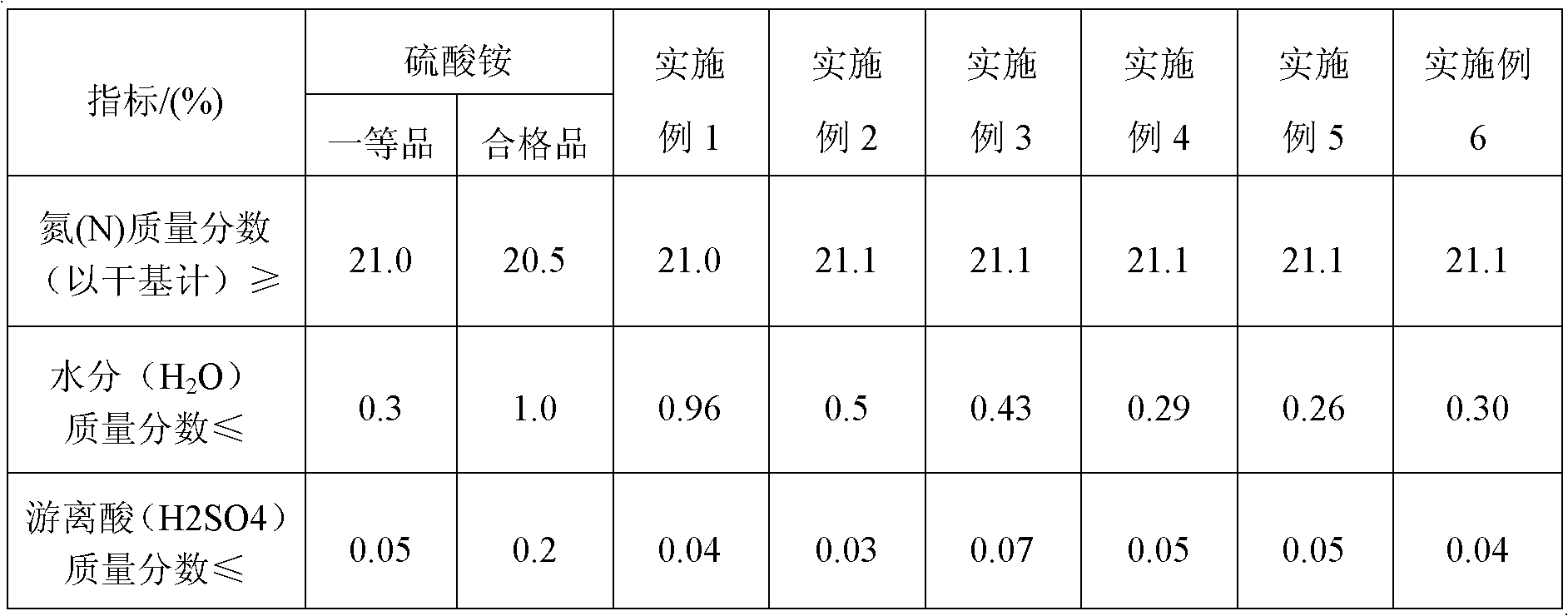

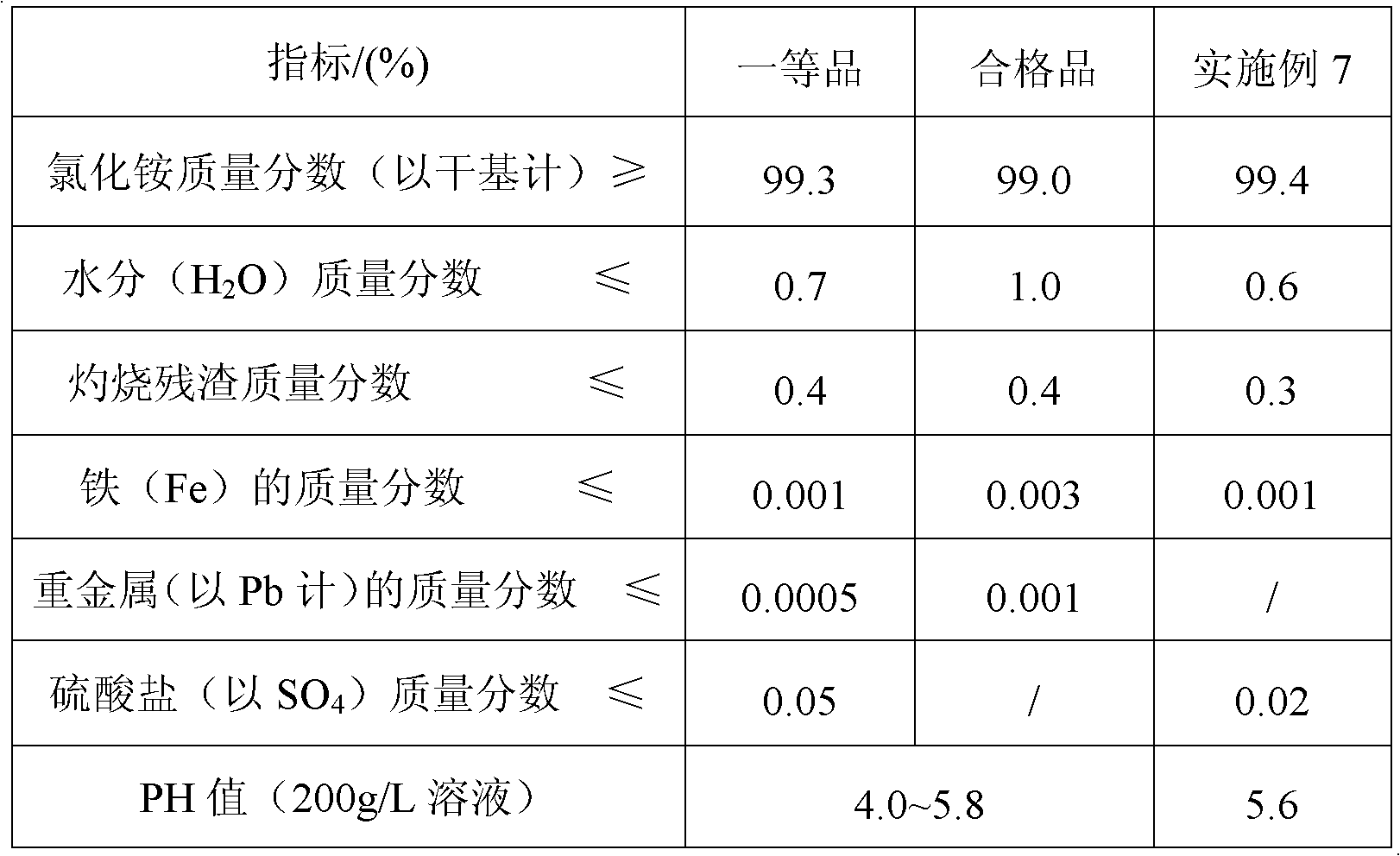

[0034] See the process flow figure 1 , put dye wastewater containing sulfuric acid in the neutralization kettle (homogeneous water taken from the dye wastewater storage tank, sulfuric acid content is about 3%, chromaticity 500 times, TOC value 1120mg / L), start stirring, add liquid ammonia to carry out And react until the pH value is 6-7, add activated carbon with a mass of 0.25% of the dye wastewater quality for decolorization, control the decolorization temperature at 25-30°C, keep stirring for 1 hour, sample and filter, the filtrate chromaticity is 8 times, and the TOC value is 45mg / L, the decolorization is completed, separated by filtration to obtain ammonium sulfate filtrate and activated carbon residue. The ammonium sulfate filtrate is concentrated and crystallized, and the separated condensed water is reused as dye synthesis bottom water or filter cake washing water. The purified ammonium sulfate wet product is further dried and used as a finished product, and the cryst...

Embodiment 2

[0036]Put dye wastewater containing sulfuric acid in the neutralization tank (taken from the mother liquor water in the production process of C.I. Disperse Blue 291:1, the sulfuric acid content is about 10%, the chromaticity is 750 times, and the TOC value is 1802mg / L), start stirring, and add liquid ammonia Carry out neutralization reaction until the pH value is 5.0, add activated carbon with a mass of 0.3% of the dye wastewater mass for decolorization, control the decolorization temperature at 30-35°C, keep stirring for 45 minutes, sample and filter, the filtrate chromaticity is 20 times, and the TOC value is 106mg / L , add 0.1% activated carbon, continue the heat preservation reaction for 1 hour, take a second sampling analysis after the reaction, the filtrate color is 14 times, the TOC value is 87mg / L, filter out the activated carbon residue, and then add 30% (w / w) hydrogen peroxide to carry out Oxidation, the hydrogen peroxide dosing mass (percentage) is 0.15% of the filtra...

Embodiment 3

[0038] Put dye wastewater containing sulfuric acid in the neutralization tank (taken from the mother liquor water in the production process of C.I. Disperse Blue 60, the sulfuric acid content is about 15%, the chromaticity is 1000 times, and the TOC value is 2140mg / L), start stirring, and add liquid ammonia to carry out And react until the pH of the wastewater is 7-8, add activated carbon with a mass of 0.4% of the dye wastewater to decolorize, control the decolorization temperature at 30-35°C, heat and stir for 45 minutes, sample and filter, the filtrate chromaticity is 40 times, and the TOC value is 125mg / L, add 0.2% activated carbon, continue the heat preservation reaction for 1 hour, take a sample analysis, the filtrate color is 20 times, the TOC value is 90mg / L, filter out the activated carbon residue, and then pass in ozonated air with a concentration of 1% (v / v) (that is, air containing 1% ozone) for oxidation, wherein the ozone dosing mass (folded amount) is 0.05% of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com