Gasoline-oxidation ammonia-process desulfurization method

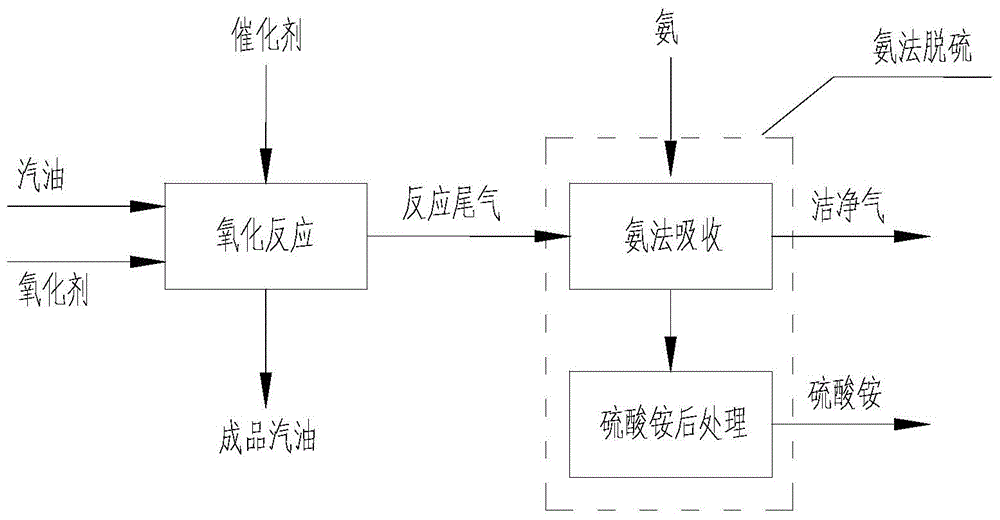

An ammonia oxidation and ammonia desulfurization technology, which is applied in the fields of chemical industry, environmental protection and oil refining to achieve the effect of high desulfurization efficiency, overcoming long process and moderate reaction conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

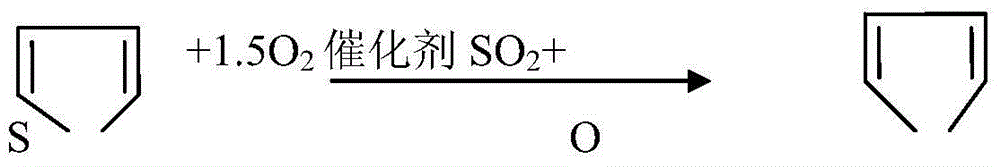

Method used

Image

Examples

Embodiment 1

[0038] Under 0.1MPa (G), 30 ℃ of reaction conditions, in the suspended bed reactor that is filled with 100g acetic acid, sulfuric acid, molecular sieve mixed catalyst, gasoline (sulfur content 1750ppm) is passed into from the reactor top with 1.5L / h rate, Air is introduced from the bottom of the reactor at a rate of 40L / h, and the desulfurized gasoline is discharged from the bottom, and the sulfur content is 8.2ppm after detection.

[0039] After the catalytic oxidation reaction, the reaction tail gas containing 0.46% SOx is discharged from the top of the reactor, sent to the ammonia desulfurization device, the absorbent is 11% ammonia water, and the specific gravity of the absorption liquid is 1.15g / cm 3 , pH5.7, circulation volume 3.1L / h, sulfur dioxide content in clean gas 30mg / Nm 3 . The obtained ammonium sulfate solution accumulates to a certain concentration, and after evaporation and crystallization, solid-liquid separation, and drying, the ammonium sulfate solid is ob...

Embodiment 2

[0041] Under the reaction conditions of 0.15MPa(G) and 40°C, in a suspended bed reactor filled with 200g of oxalic acid, phosphoric acid, and molecular sieve mixed catalyst, gasoline (sulfur content 1250ppm) was fed from the top of the reactor at a rate of 20L / h , using 28% oxygen enrichment to pass through the bottom of the reactor at a rate of 200L / h, and the finished gasoline after desulfurization is discharged from the bottom, and the sulfur content is 7.6ppm after detection.

[0042]After the catalytic oxidation reaction, the reaction tail gas containing 0.88% SOx is discharged from the top of the reactor, sent to the ammonia desulfurization device, the absorbent is liquid ammonia, and the specific gravity of the absorption liquid is adjusted to 1.16g / cm 3 , pH6.3, circulation volume 34.1L / h, sulfur dioxide content in clean gas is 25mg / Nm 3 . The obtained ammonium sulfate solution accumulates to a certain concentration, and after evaporation and crystallization, solid-li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com