Cleaning method and cleaning device

a cleaning method and cleaning technology, applied in the field of cleaning methods and cleaning devices, can solve the problems of low efficiency in use of nf3 and loss of activation energy, and achieve the effect of increasing the efficiency in gas use and further increasing the efficiency in cleaning gas us

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

(First Embodiment)

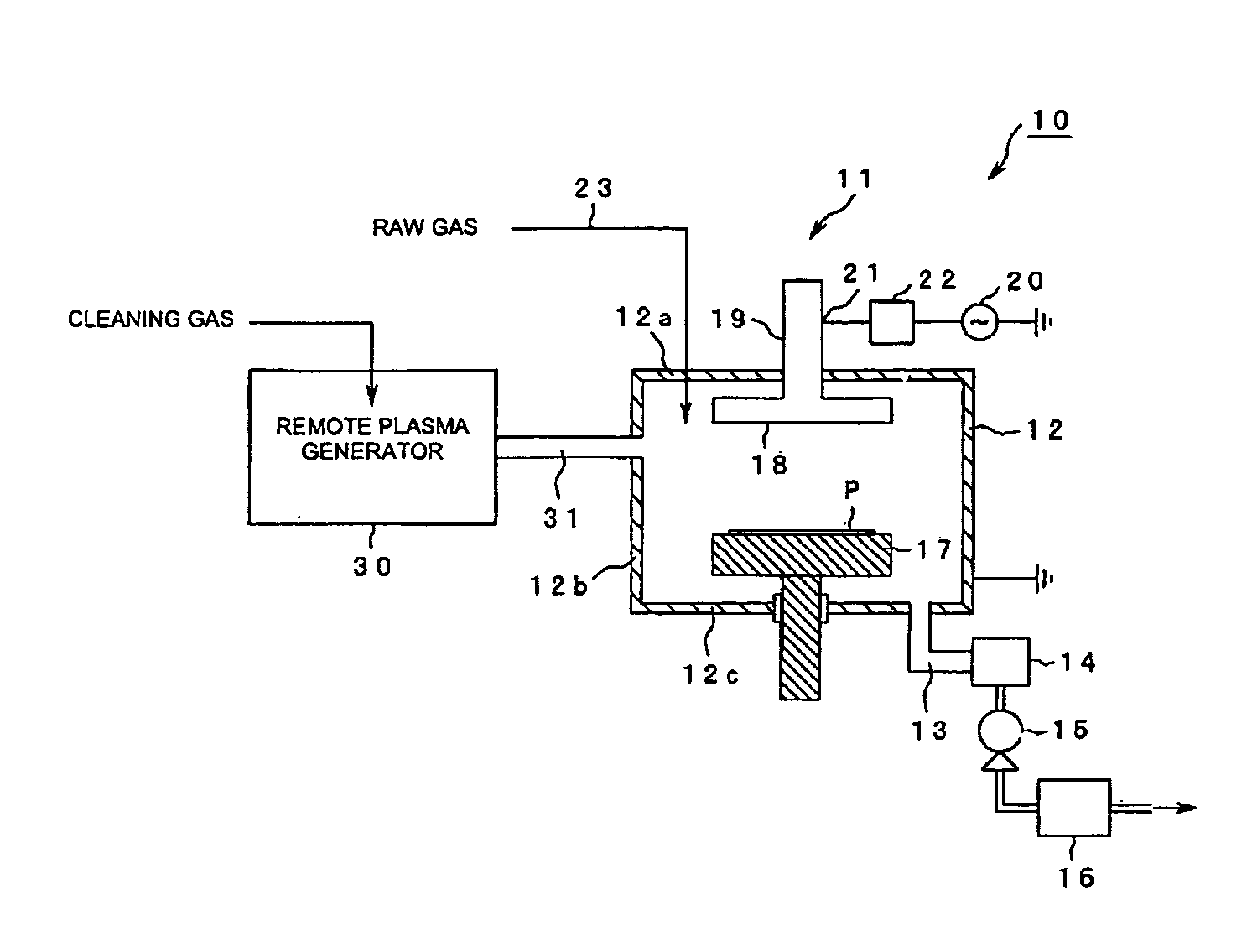

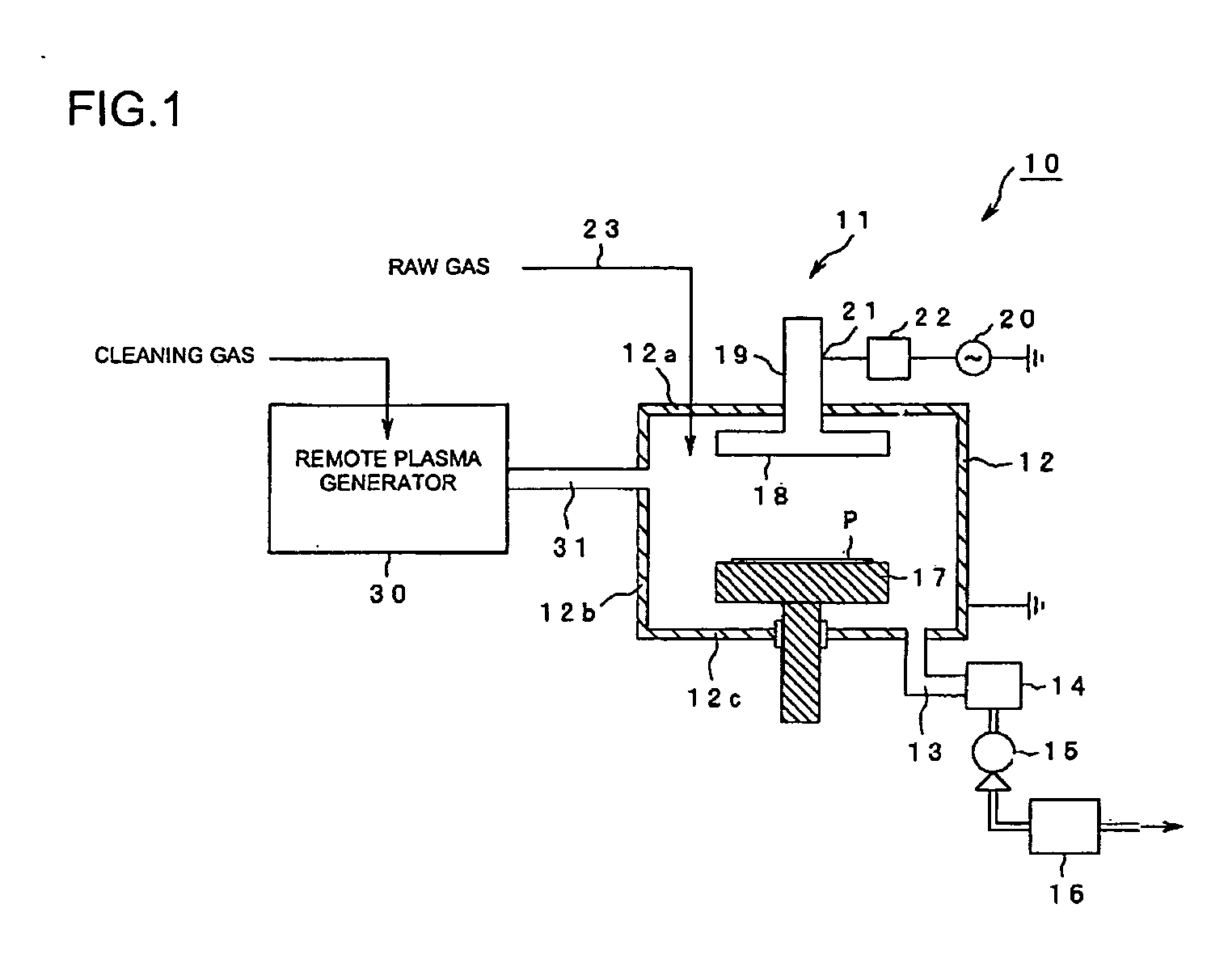

[0032]FIG. 1 is a diagram explaining a cleaning method of a first embodiment of the invention. In the embodiment, the method for cleaning the process chamber of the CVD device will be explained. As for the CVD device, a cleaning device for the plasma CVD device is exemplified.

[0033] As shown in FIG. 1, a cleaning device 10 includes a plasma CVD device 11 and a remote plasma generator 30. The plasma CVD device 11 includes a process chamber 12 kept in vacuum condition (reduce pressure condition), which can be kept at a constant vacuum condition (reduced condition) by exhausting gas from inside the chamber to the outside through an exhaust gas path 13 provided at a bottom wall 12c of the process chamber 12, a high vacuum pump 14, a lower vacuum pump 15, and a detoxification device 16. The detoxification device 16 is the device to turn out the exhausted gas to be harmless and to exhaust it to the outside in an exhausting process before CVD film deposition or after cle...

second embodiment

(Second Embodiment)

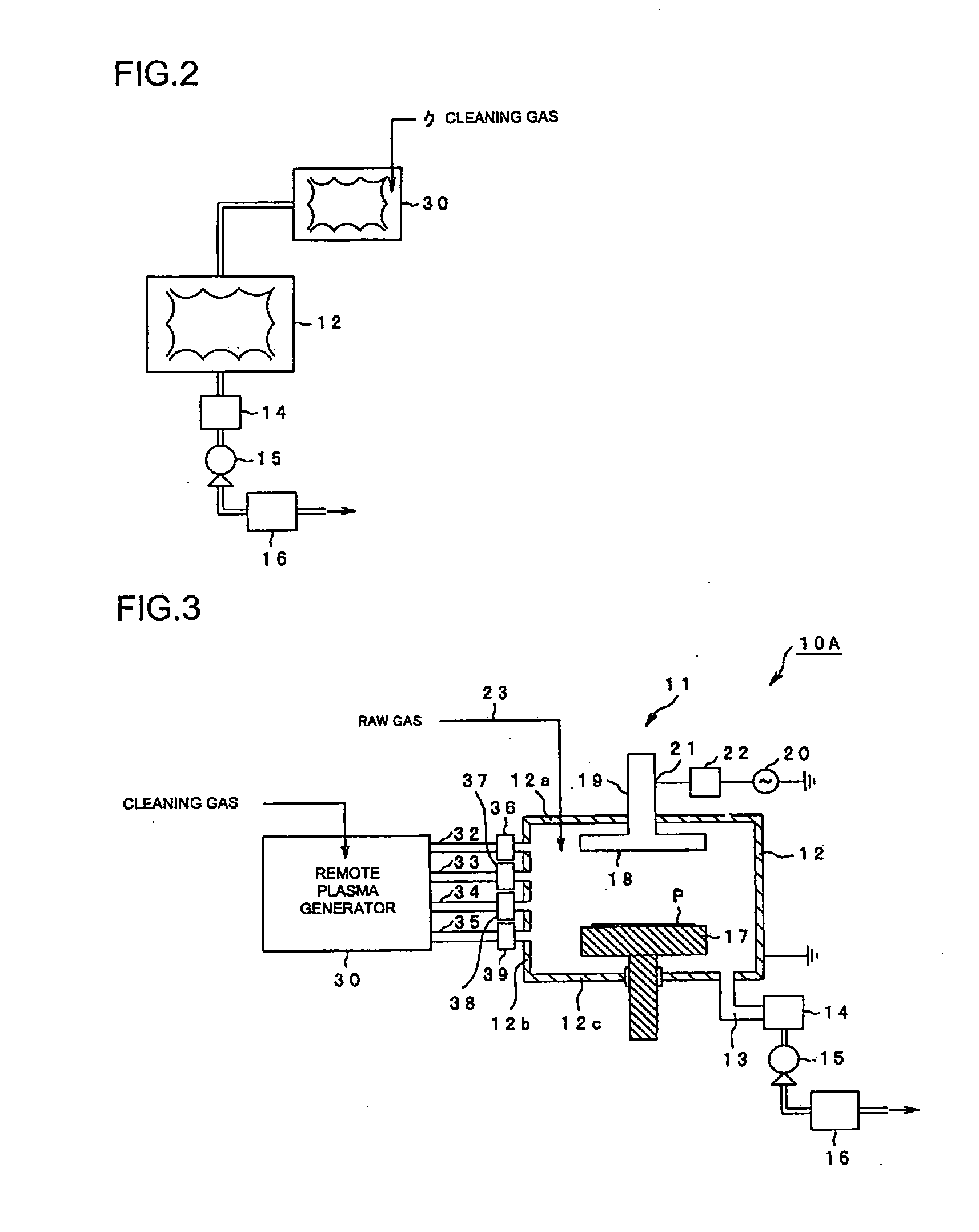

[0052]FIG. 3 is a diagram illustrating a cleaning device to explain a cleaning method of a second embodiment of the invention. In FIG. 2, the same code is given to the part that is same as that in FIG. 1 for explanation.

[0053] In FIG. 3, the cleaning device 10A includes the plasma CVD device 11, the remote plasma generator 30, and a plurality of plasma sources, each of which is correspondingly provided to each of a plurality of pipes that connect the plasma CVD device 11 and the remote plasma generator 30. Specifically, activated gas is led out from the remote plasma generator 30, which is the first plasma source, through a plurality of pipes. In this case, four pipes, namely, pipes 32, 33, 34, and 35 are shown in FIG. 2. The plurality of plasma sources are provided to the pipes correspondingly to be a third plasma source. In this case, four plasma sources, namely, plasma sources 36, 37, 38, and 39 are shown in FIG. 2. Each of the plurality of plasma sources is p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Frequency | aaaaa | aaaaa |

| Vacuum | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com