Preparation method and application of metal organic framework material

A metal-organic framework, reaction technology, applied in applications, iron-organic compounds, organic compounds/hydrides/coordination complex catalysts, etc., can solve problems such as refractory degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

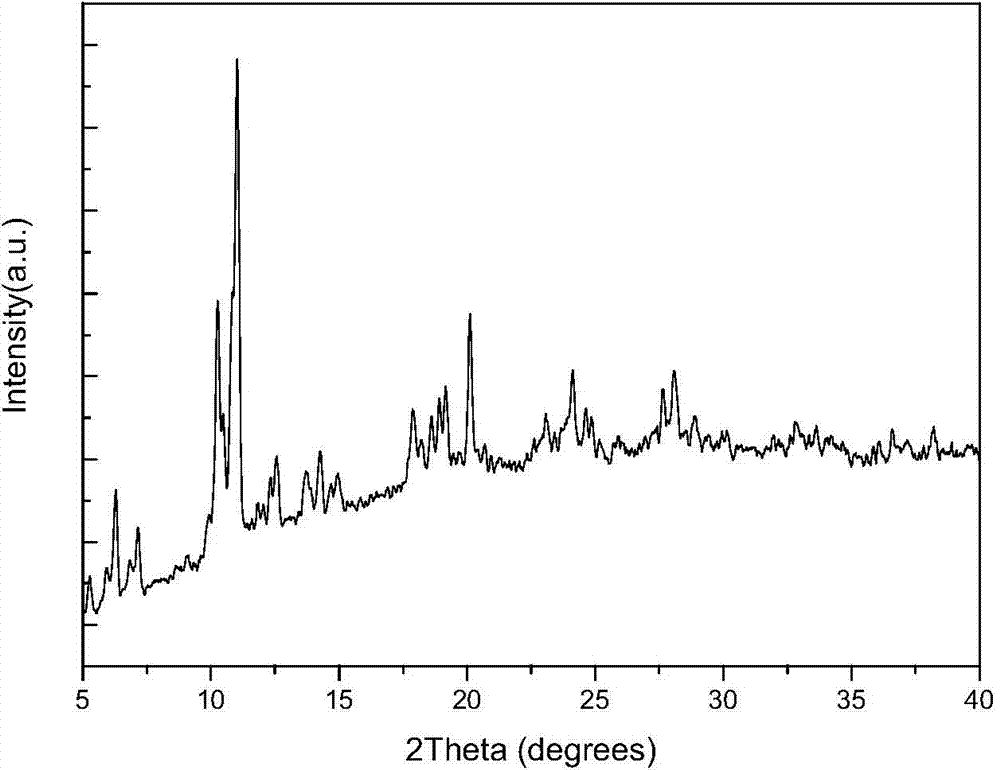

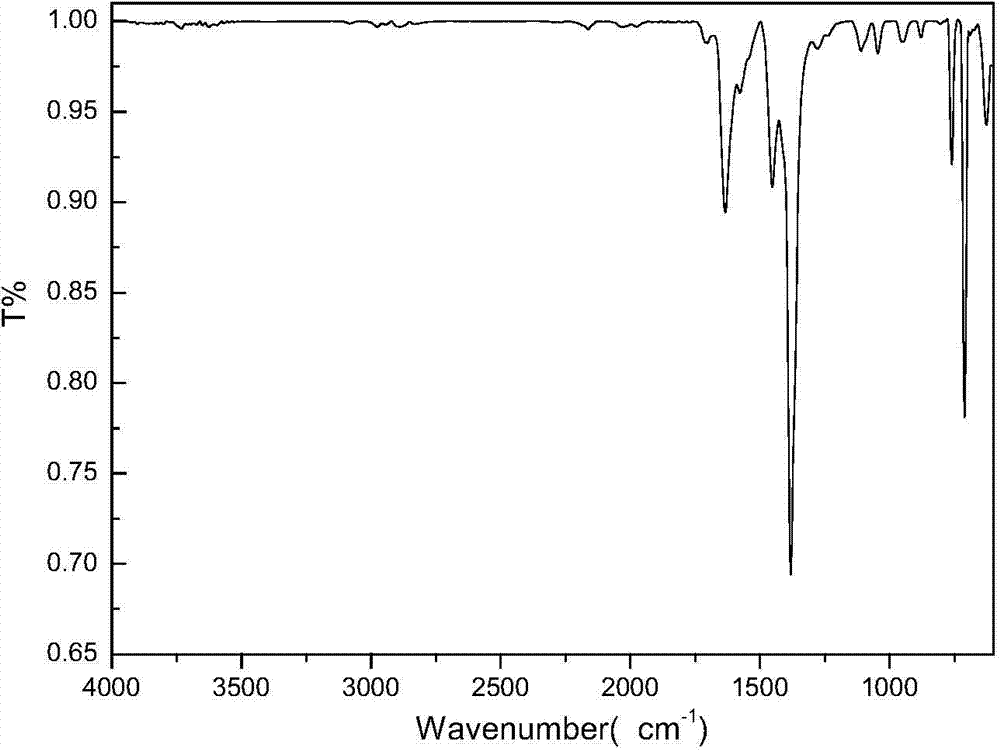

[0102] The MOF(Fe) material was synthesized by hydrothermal method, and 5.7714g Fe(NO 3 ) 3 9H 2 Dissolve O in 72ml of deionized water, add 5.71ml of 5M hydrofluoric acid, stir well to dissolve it, weigh 1.98g of 1,3,5-trimellitic acid and add it to a 100ml reaction vessel with a Teflon reaction liner In the kettle, pour the dissolved ferric nitrate solution into it and seal it. The reaction kettle was heated in an oven at 150° C. for 16 hours. After the reaction was completed, it was naturally cooled to room temperature, and centrifuged to obtain a light orange solid. Disperse 1 g of the light orange solid obtained above into 300 ml of deionized water, heat it in a water bath to 80 ° C, and perform magnetic stirring at the same time, cool to room temperature after 4 hours and centrifuge; then mix the sample with 100 ml of absolute ethanol and heat it in a water bath to 60 °C ℃ while magnetically stirring for 2 hours, after the solution was cooled to room temperature, it w...

Embodiment 2

[0104] The MOF(Fe) material was synthesized by hydrothermal method, and 5.7714g Fe(NO 3 ) 3 9H 2Dissolve O in 65ml of deionized water, add 4.30ml of 5M hydrofluoric acid, stir well to dissolve it, weigh 1.52g of 1,3,5-trimellitic acid and add it to a 100ml reaction vessel with a Teflon reaction liner In the kettle, pour the dissolved ferric nitrate solution into it and seal it. The reaction kettle was heated in an oven at 140° C. for 12 hours. After the reaction was completed, it was naturally cooled to room temperature, and centrifuged to obtain a light orange solid. Disperse 1 g of the light orange solid obtained above into 200 ml of deionized water, heat in a water bath to 70 ° C, and perform magnetic stirring at the same time, cool to room temperature after 3 hours and centrifuge; then mix the sample with 60 ml of absolute ethanol and heat in a water bath to 50 ℃ while magnetically stirring for 2 hours, after the solution was cooled to room temperature, it was centrifu...

Embodiment 3

[0106] The MOF(Fe) material was synthesized by hydrothermal method, and 5.7714g Fe(NO 3 ) 3 9H 2 Dissolve O in 77ml of deionized water, add 11.42ml of 5M hydrofluoric acid, stir well to dissolve it, weigh 2.39g of 1,3,5-trimellitic acid and add it to 100ml of Teflon reaction liner for reaction In the kettle, pour the dissolved ferric nitrate solution into it and seal it. The reaction kettle was heated in an oven at 160° C. for 24 hours. After the reaction was completed, it was naturally cooled to room temperature, and centrifuged to obtain a light orange solid. Disperse 1 g of the light orange solid obtained above into 400 ml of deionized water, heat in a water bath to 80 ° C, and perform magnetic stirring at the same time, cool to room temperature after 5 hours and centrifuge; then mix the sample with 100 ml of absolute ethanol in a water bath and heat to 70 ℃ while magnetically stirring for 4 hours, after the solution was cooled to room temperature, it was centrifuged an...

PUM

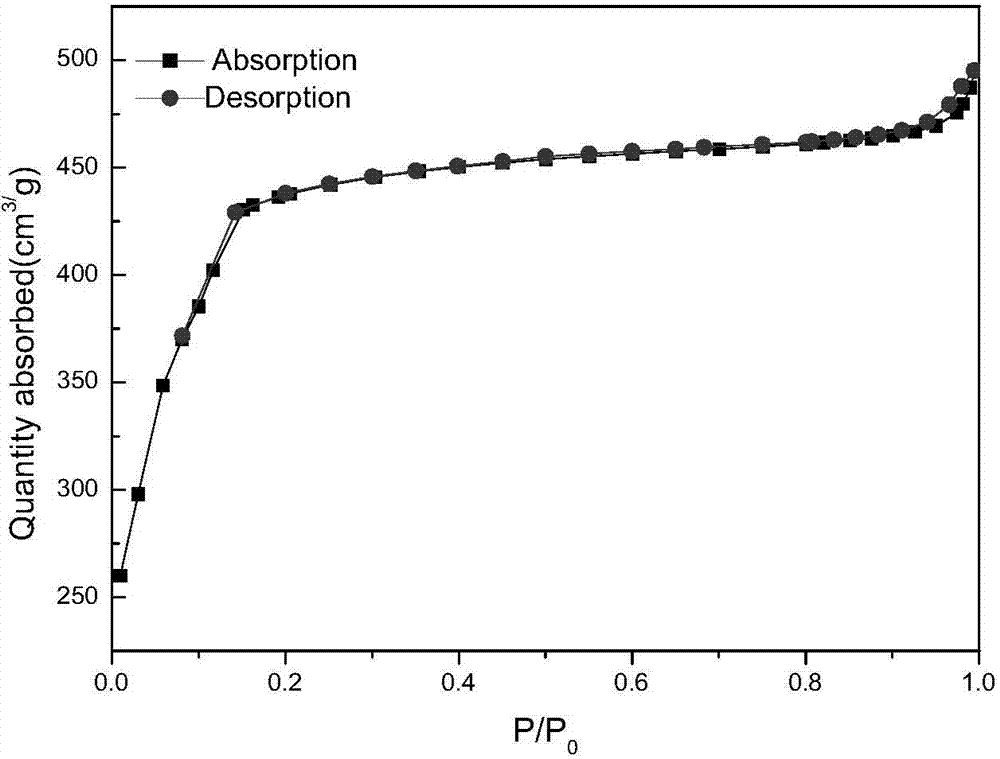

| Property | Measurement | Unit |

|---|---|---|

| Pore volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com