Preparation method of visible-light activated cuprous oxide/titanium dioxide nano-composite photocatalyst and applications thereof

A technology of titanium dioxide and cuprous oxide, which is applied in the field of environmental pollution control, can solve the problem that the photocatalytic properties have not been better applied, and achieve the improvement of visible light catalytic activity and stability, broaden the range of photoresponse, and improve the separation efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

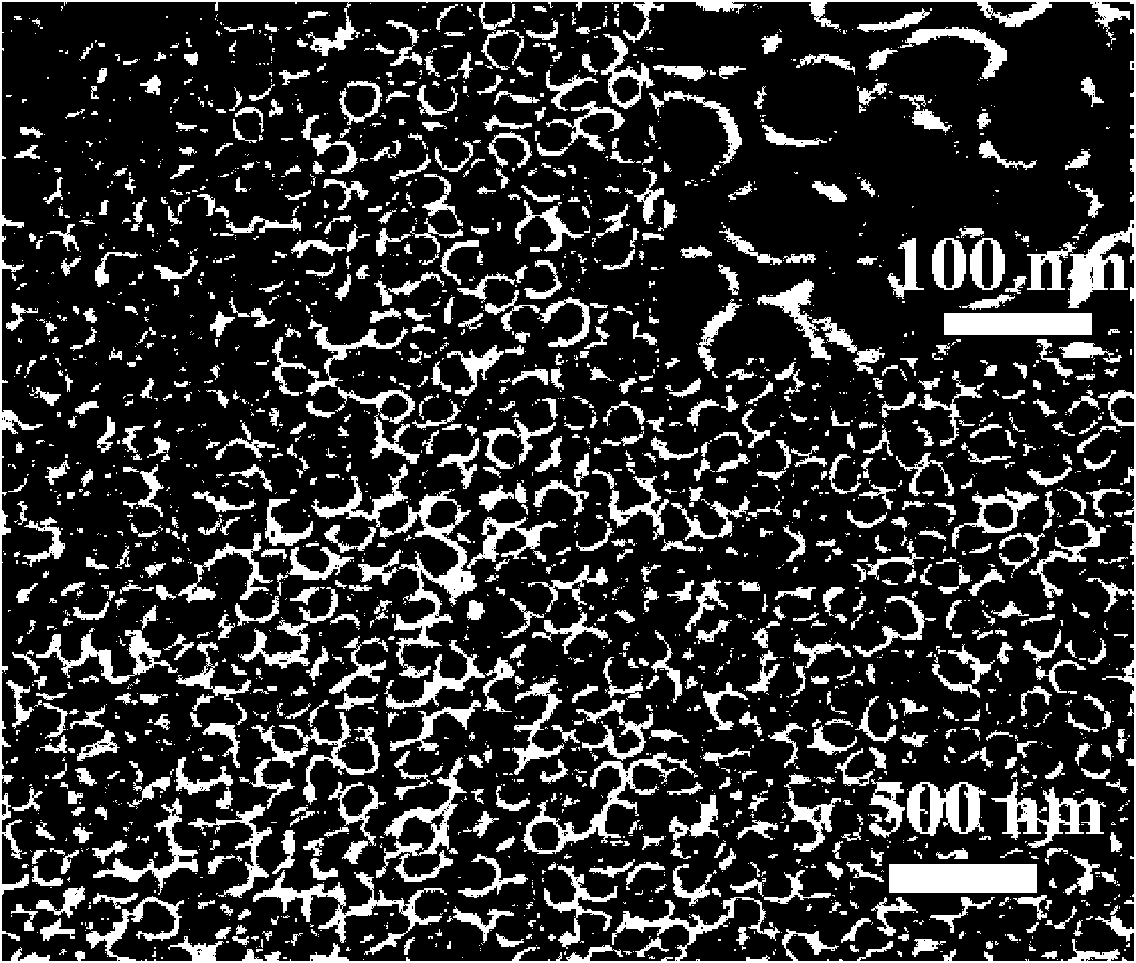

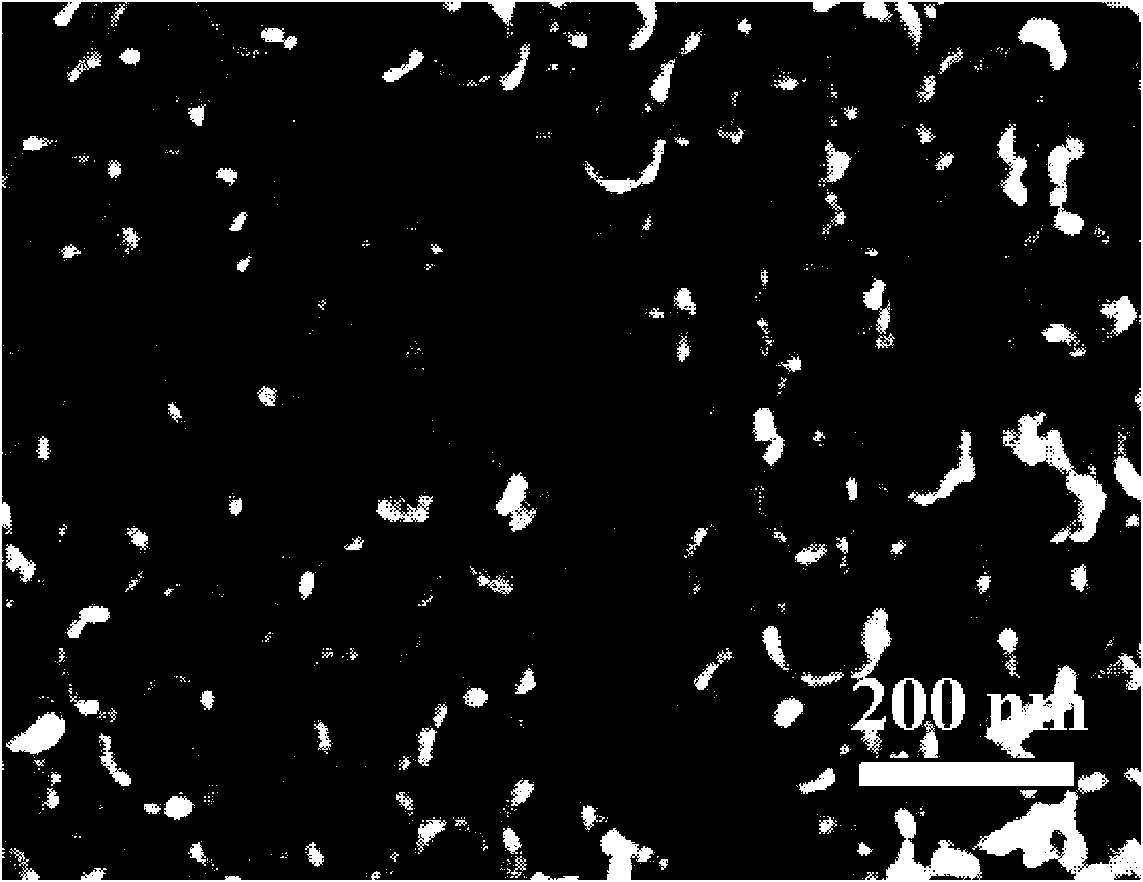

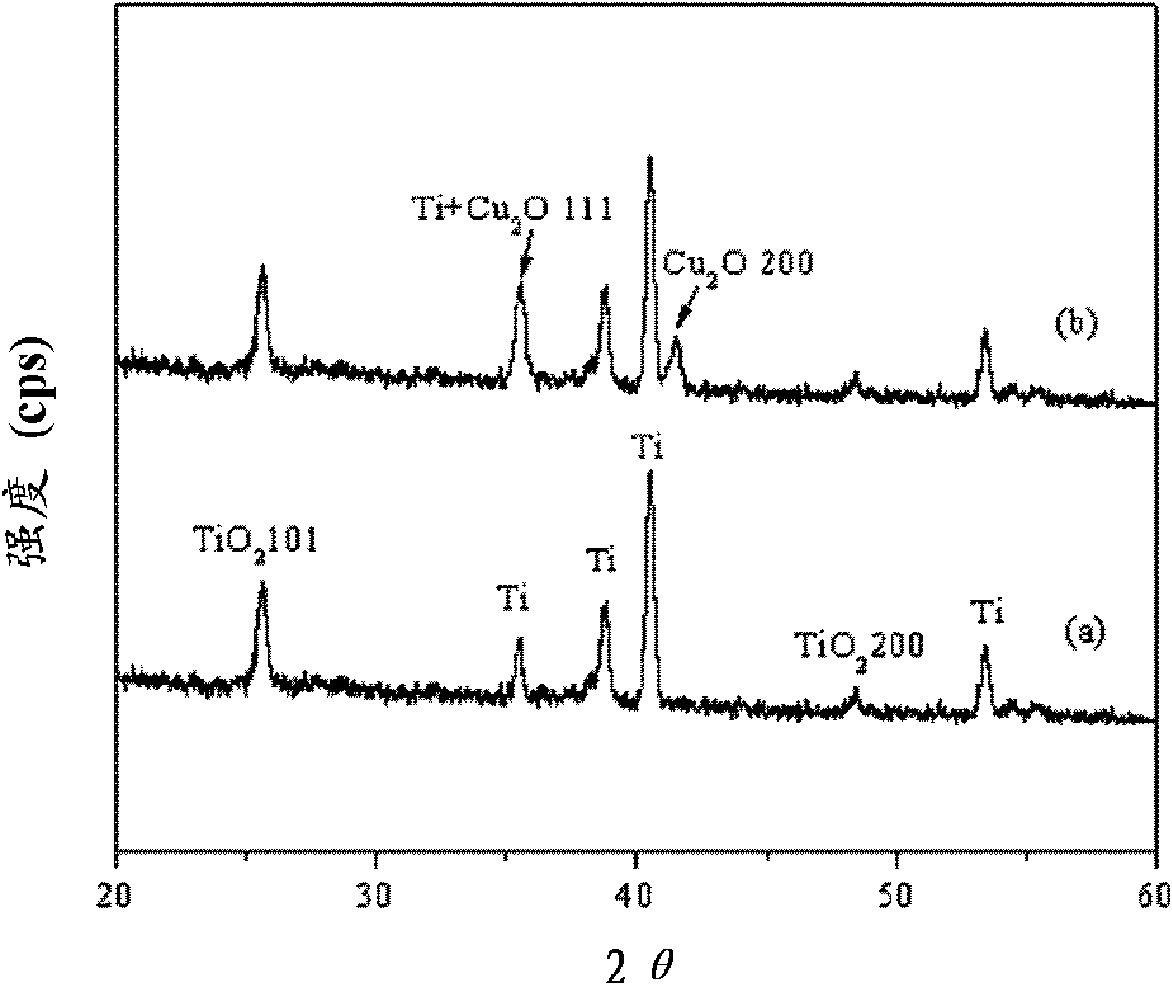

Embodiment 1

[0031] Cut industrial pure titanium sheet into several 20mm? 0mm size titanium sheet. Grind repeatedly with 240#, 400#, 800# and 1500# emery paper until the surface is clean and smooth, then place it in an ultrasonic oscillation pool for ultrasonic cleaning, and then immerse in HF:HNO 3 :H 2 Etching in a mixed solution of O=1:4:5 for 40 seconds, and cleaning the last etched titanium sheet with ethanol solution and deionized water for 20 minutes respectively. The treated titanium sheets were air-dried naturally for later use. Connect the titanium sheet and the platinum sheet to the positive and negative poles of the DC stabilized power supply respectively. The electrolyte is composed of hydrofluoric acid, and the concentration of hydrofluoric acid in the electrolyte is 0.2wt%. On the DC stabilized power supply. In the constant current anodizing process, the anodic oxidation voltage and time are first oxidized at 0-20V for 5 minutes, then the voltage is stabilized at 20V, an...

Embodiment 2

[0033] According to the preparation method of the present invention in Example 1, only the electrolytic solution was replaced with hydrofluoric acid with a concentration of 0.05 wt%, to prepare a cuprous oxide / titania nanocomposite photocatalyst.

Embodiment 3

[0035] According to the preparation method of the present invention in Example 1, only the electrolytic solution was replaced with hydrofluoric acid with a concentration of 1.0 wt%, to obtain a cuprous oxide / titania nanocomposite photocatalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com