Method and device for eliminating pyrophoric by-products from ion implantation technology

A technology of ion implantation and spontaneous combustion, which is applied in the direction of metal material coating process, coating, gaseous chemical plating, etc., and can solve problems such as inappropriate design, harmful and harmful to human health and environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

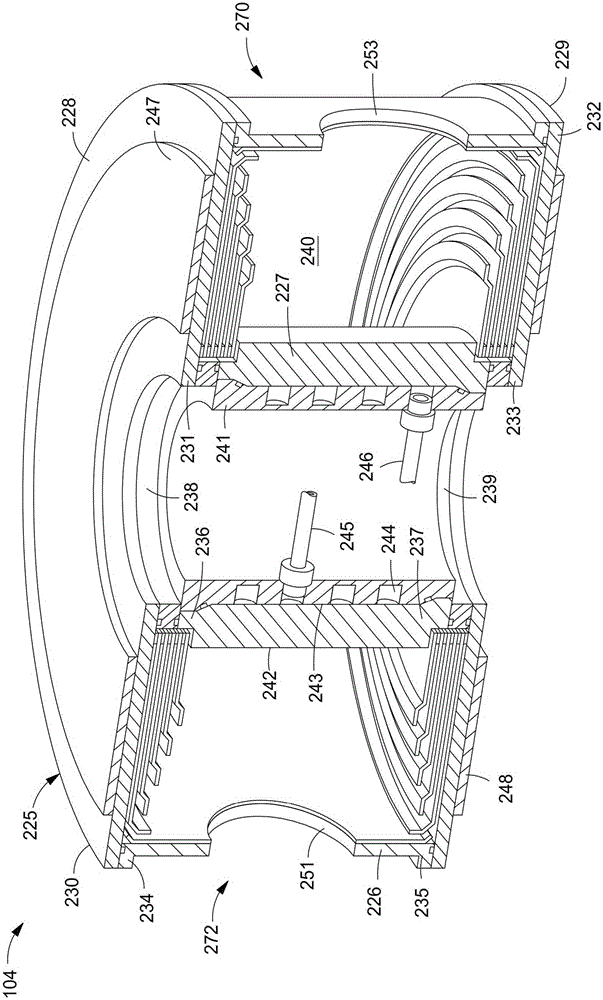

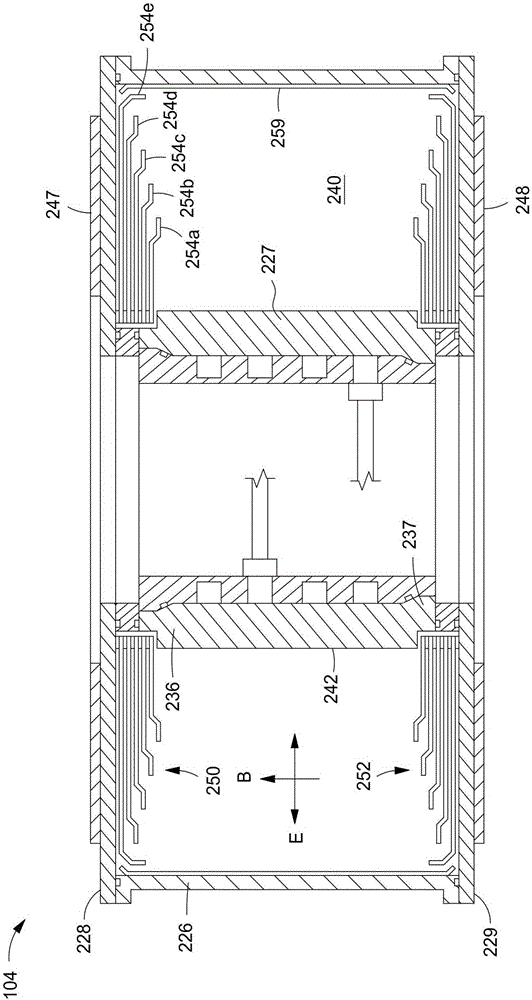

[0017] Embodiments disclosed herein generally relate to plasma abatement processes and apparatus. Plasma abatement processes take foreline effluent from a processing chamber, such as an injection chamber, and react the effluent with reactants when the effluent contains pyrophoric byproducts. A plasma generator placed within the foreline path ionizes the effluent and reactants to facilitate the reaction between the effluent and reactants. Under conditions within the exhaust gas flow path, the ionized species react to form compounds that remain in the gas phase. In another embodiment, ionized species can react to form compounds that condense from the gas phase. The condensed particulate matter is then removed from the effluent by a collector. The apparatus may include an injection chamber, a plasma generator, one or more pumps and a scrubber.

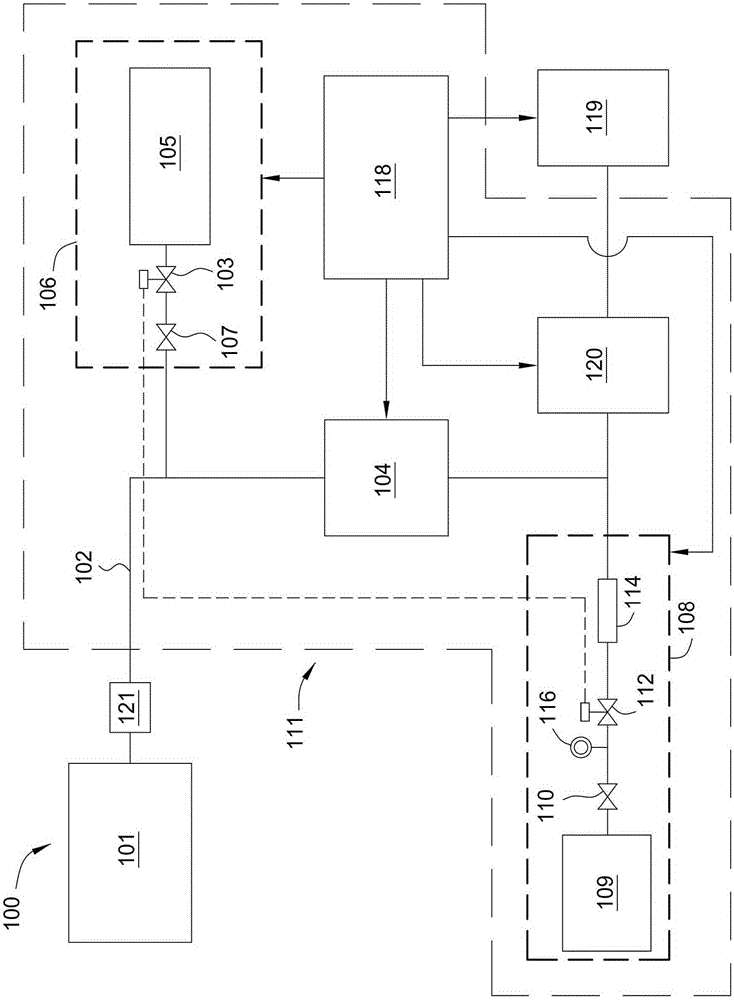

[0018] figure 1 A schematic diagram of a processing system 100 according to embodiments disclosed herein is shown. The processing s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com