Technological cavity oxygen concentration detecting system and technological cavity oxygen concentration detecting method

A technology of oxygen concentration and detection system, which is applied in the field of gas pipeline control and semiconductor manufacturing, can solve the problems of uncertain nitrogen volume, inaccurate setting operation, uncertain degree of dilution, etc., to achieve consistency and avoid product defects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the content of the present invention clearer and easier to understand, the content of the present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

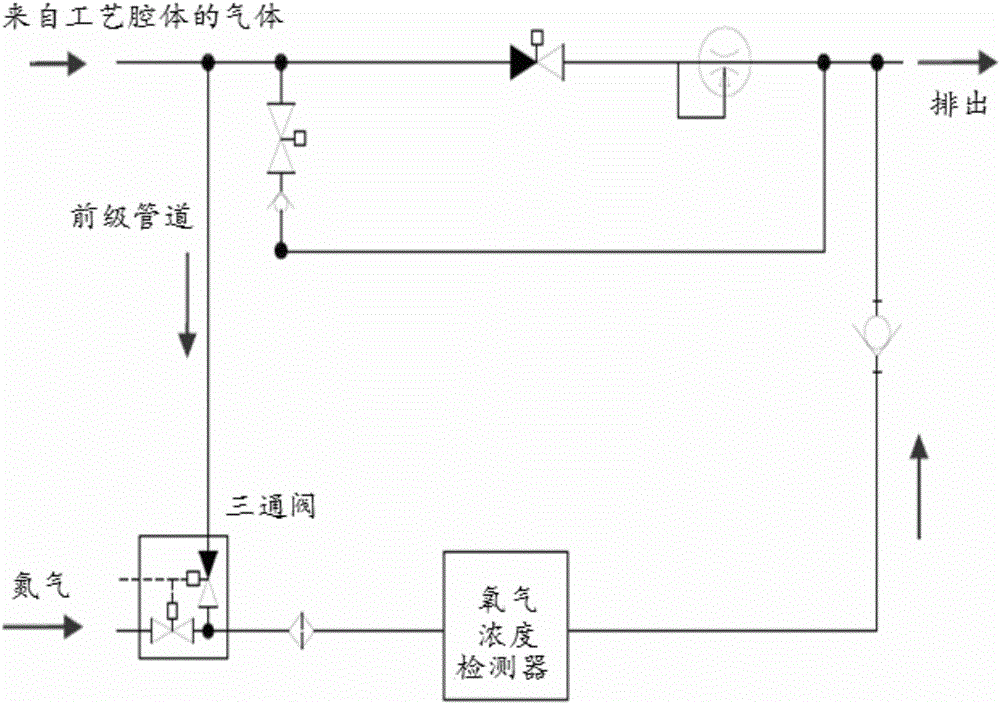

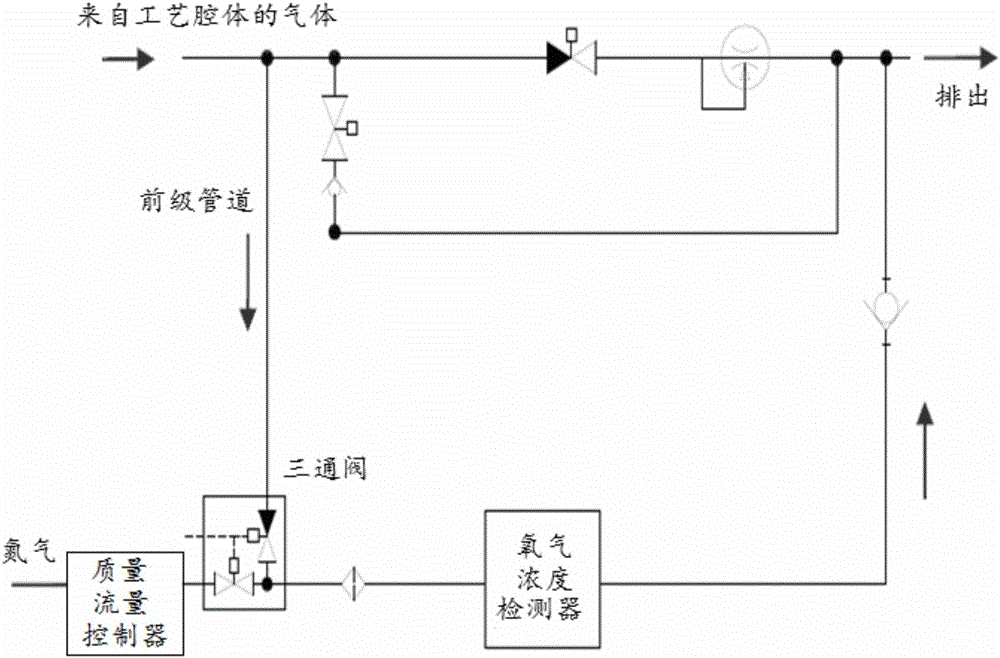

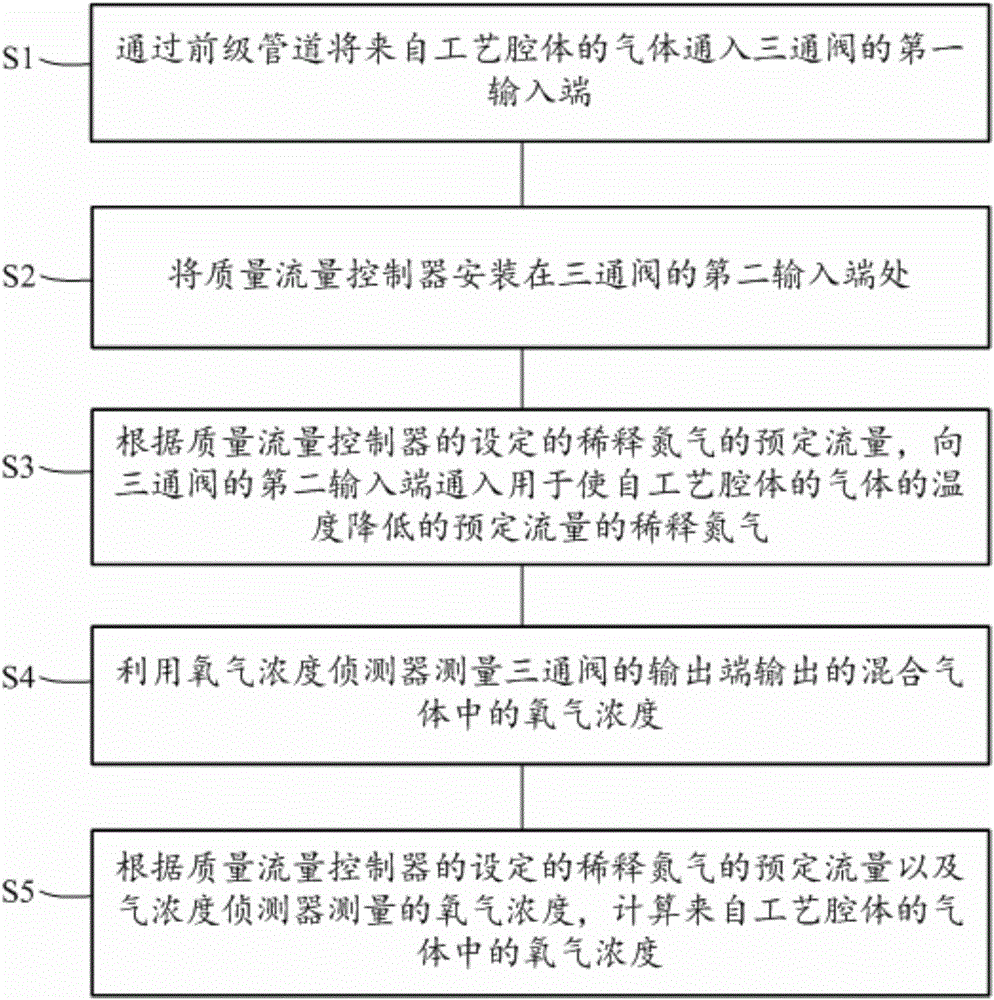

[0027] Currently, if figure 1 As shown, when detecting the oxygen concentration of the process chamber, the gas from the process chamber flows into the three-way valve through the foreline pipeline, and the nitrogen dilution circuit flows into the three-way valve at the same time, and the gas is mixed and then flows into the oxygen concentration detector for detection . When the oxygen concentration is higher than the set value of the process parameters, the process chamber is fed with nitrogen to dilute until the concentration measured by the oxygen concentration detector is lower than the set value of the process, the detection of the oxygen concentration is stopped, and the three-way valve is closed. The process chamber starts the subsequent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com