Apparatus for treating an exhaust gas in a foreline

A vacuum pipeline and pre-stage technology, applied in mechanical equipment, exhaust treatment, discharge tubes, etc., can solve problems such as corrosion and poor dielectric tubes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

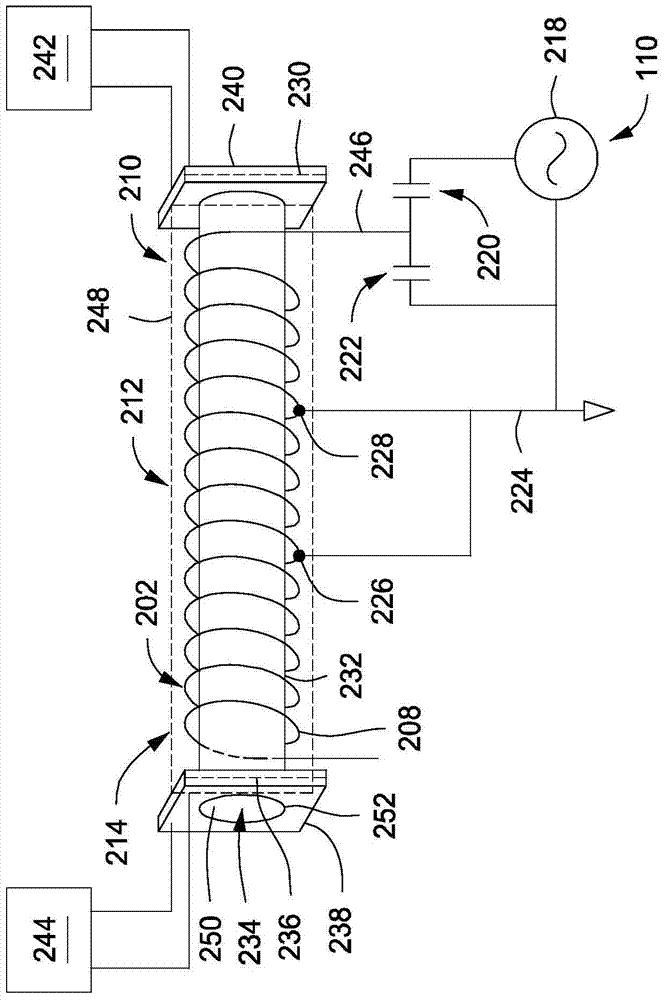

[0011] Devices for treating exhaust gases in forelines are provided here. Embodiments of the apparatus of the present invention may advantageously reduce, slow down, or eliminate corrosion of components (eg, dielectric or ceramic tubes) compared to conventional plasma-driven gas processing systems.

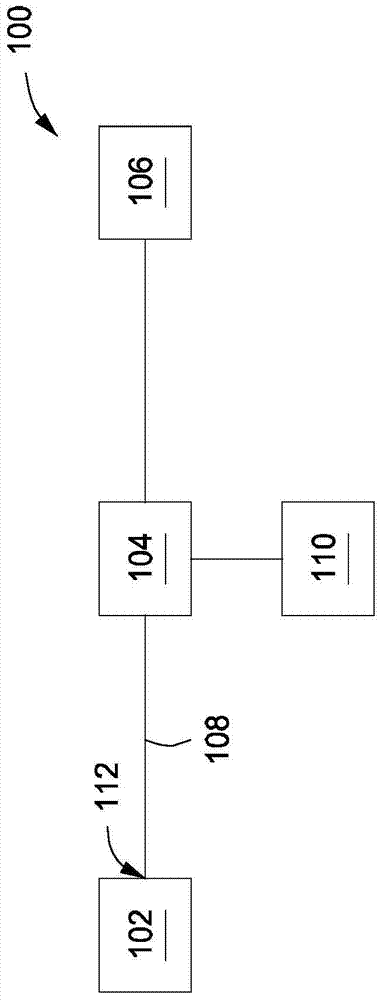

[0012] figure 1 Is a schematic illustration of a treatment system 100 suitable for use with an apparatus for treating exhaust in a backing line according to some embodiments of the present invention. The processing system 100 generally includes a processing chamber 102, a foreline 108 coupled to the processing chamber 102, and an apparatus 104 for treating exhaust gas coupled to the foreline.

[0013] The processing chamber 102 may be any processing chamber suitable for performing processing on a substrate. In some embodiments, the processing chamber 102 may be part of a processing tool, such as a cluster tool, an in-line processing tool, or the like. Non-limiting examples of s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com