Large vacuum glow power generation nano-film coating equipment and working mode thereof

A nano-film and vacuum coating technology, which is applied in the direction of vacuum evaporation plating, metal material coating process, coating, etc., to achieve the effects of increasing deposition speed, improving social and economic efficiency, and improving coating uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

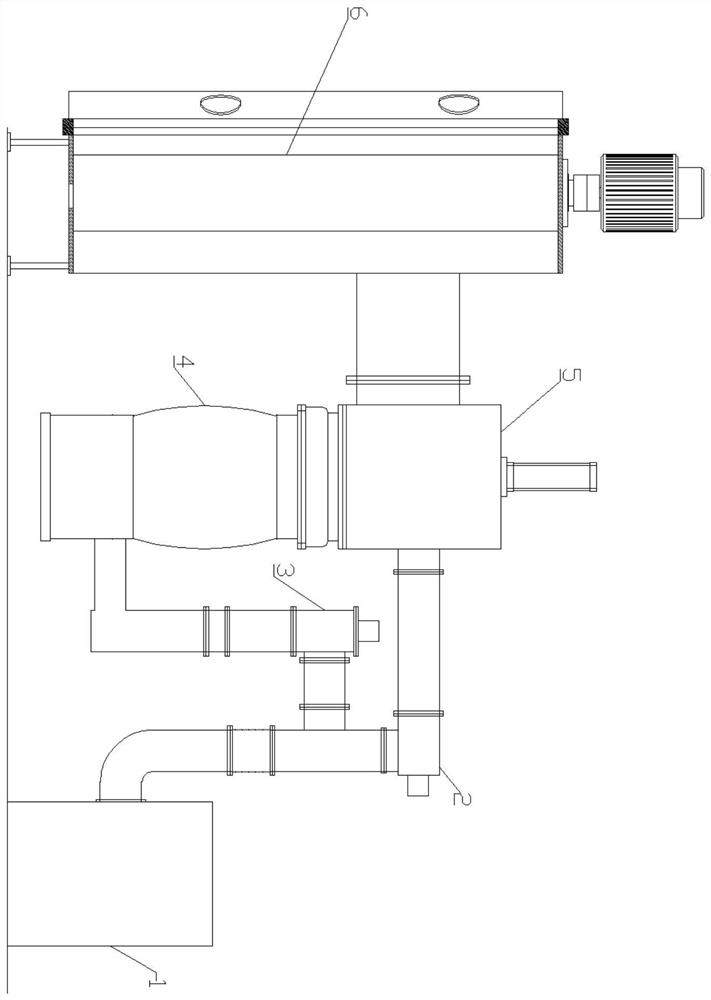

[0044] Such as figure 1 Shown is the front view of the present invention, including slide valve pump 1: a slide valve is housed in the pump body, and an eccentric wheel is housed in the slide valve, and the shaft leading to the outside of the pump cylinder drives the eccentric wheel to rotate, and the outer circle of the slide valve is at the center of the pump cylinder. The surface slides, and the upper part of the slide valve freely slides up and down and swings left and right in the semicircular slide valve guide rail; the upper part of the slide valve is hollow, and the gas passes through the hollow part of the slide valve, and the compressed gas pushes the exhaust valve out of the pump. , so the cycle works;

[0045] Pre-pumping valve 2: After the slide valve pump is started, the pre-pumping valve is mainly used for rough pumping, which is used for low vacuum and closed for high pumping;

[0046] Fore-stage valve 3: After the rough pumping is completed, the pre-pumping v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com