Plastic retaining type polyether assemblage carboxylic acid high-performance water reducing agent and preparation method thereof

A technology of polyether and polycarboxylic acid, which is applied in the field of concrete high-performance water reducer, plastic-retaining polyether polycarboxylate high-performance water reducer and its preparation, and can solve the problem of small initial slump of concrete and initial Dispersion ability is not strong, the water reducing rate of the water reducing agent is low, etc., to achieve the effect of small loss of slump and expansion, good dispersion and retention performance, and high water reducing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

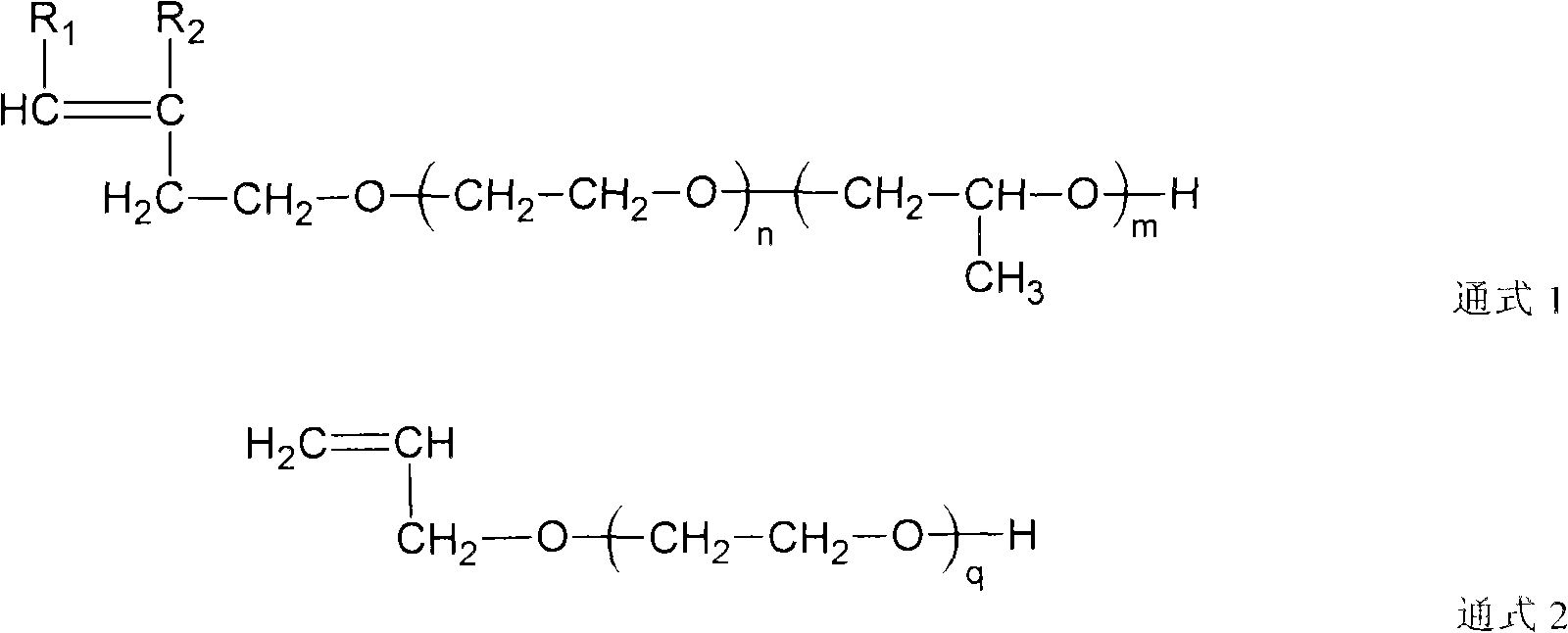

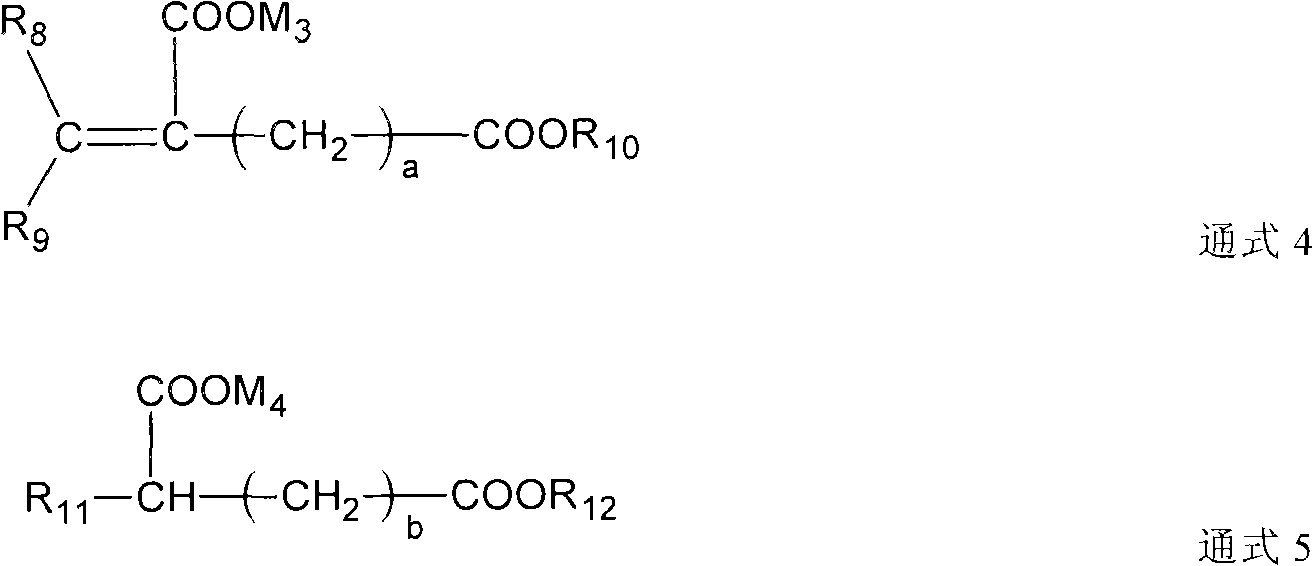

Method used

Image

Examples

Embodiment 1

[0079] Add 272.4g deionized water, 1200g methyl alkenyl polyoxyethylene ether (molecular weight is 2400), 7.2g acrylic acid, 196g maleic anhydride in the glass flask that is equipped with stirrer, thermometer, dropping device, reflux cooler and 14.4g sodium propylene sulfonate, stirred and heated up to 80°C, dissolved 7.1g potassium persulfate in 702.9g deionized water to prepare a 1% concentration initiator solution, and added 497g once at 80°C to the above-mentioned glass flask Initiator solution, react at a constant temperature at 80°C for 1 hour, then add the remaining initiator solution at one time, react at a constant temperature at 80°C for 1 hour, cool to 40°C after the reaction, add 30% sodium hydroxide aqueous solution to adjust the pH value to 5 , adjusting the concentration of the polymer to 40%, to obtain the plastic-retaining polyether polycarboxylate high-performance water reducer of the embodiment of the present invention, code-named PC-1.

Embodiment 2

[0081] Add 100g of deionized water, 60g of methyl alkenyl polyoxyethylene ether (molecular weight is 4800), 360g of allyl polyoxyethylene ether in a glass flask equipped with a stirrer, thermometer, dropping device, and reflux cooler (molecular weight is 2400), 180g allyl polyoxyethylene ether (molecular weight is 1200) and 48g methallyl sulfonic acid, stirring is heated up to 70 ℃, and 171g ammonium persulfate is dissolved in 969g deionized water and is formulated into 15 The initiator solution of % concentration, 480g hydroxypropyl methacrylate, 12g citraconic anhydride and 20g deionized water are mixed with mixed monomer solution, at 70 ℃, in above-mentioned glass flask, drip initiator solution and Mix the monomer solution, drop it in 4 hours, react at a constant temperature at 70°C for 4 hours, cool to 45°C after the reaction, add 30% sodium hydroxide aqueous solution to adjust the pH value to 6, adjust the concentration of the polymer to 40%, and obtain this product The p...

Embodiment 3

[0083] Add 110g of deionized water, 540g of methyl alkenyl polyoxyethylene ether (molecular weight is 1200), 60g of allyl polyoxyethylene ether in a glass flask equipped with stirrer, thermometer, dropping device, and reflux cooler (molecular weight is 2400), 72g sodium methacrylate, stir and heat up to 65 ℃, 25.5g ammonium persulfate is dissolved in 156.5g deionized water and is mixed with the initiator solution of 14% concentration, 200g fumaric acid, 400g Itaconic acid and 2.4g of acrylic acid were dissolved in 843.6g of deionized water to prepare a mixed monomer solution. At 65°C, the initiator solution and the mixed monomer solution were simultaneously added dropwise at a controlled rate in the above glass flask, and the dripping was completed in 3 hours, 65 ℃ for 2 hours at a constant temperature, cooled to 35 ℃ after the reaction, added ethylenediamine to adjust the pH value to 7, and adjusted the concentration of the polymer to 40%, to obtain the plastic-retaining polye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com