Alicyclic structure ester polymer and composite, preparation method and use

A technology of polymers and composites, applied in the field of ester polymers, to achieve the effects of reducing viscosity, ensuring the degree of curing, and reducing residual small molecules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

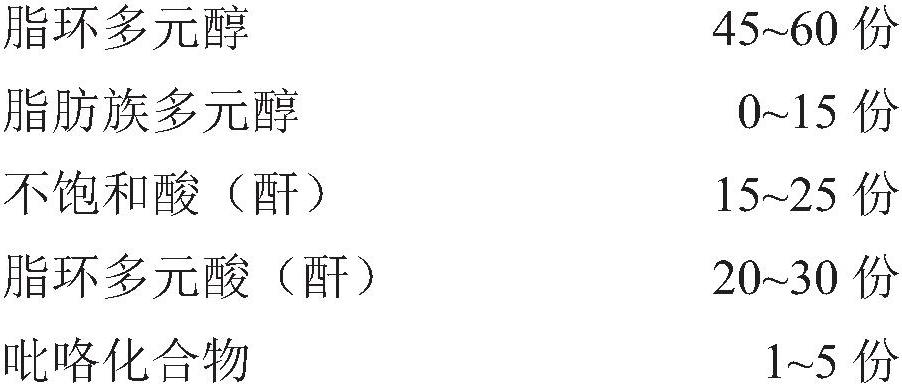

Method used

Image

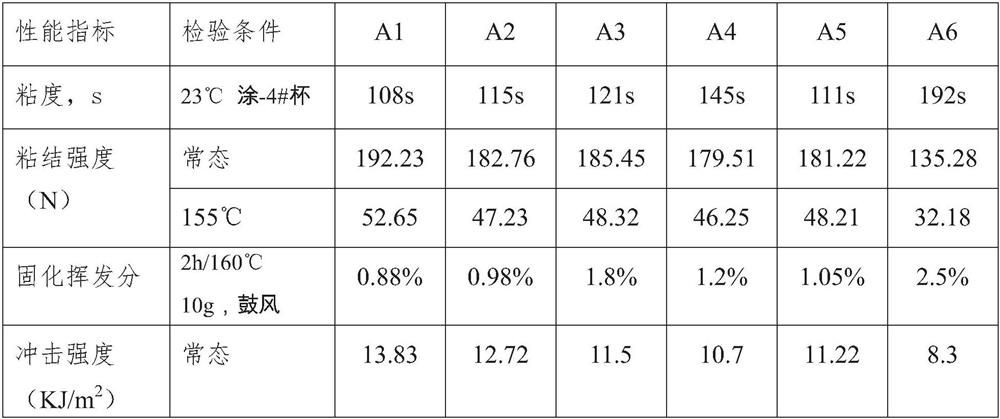

Examples

Embodiment 1

[0049] 220g 1,4-cyclohexanedimethanol, 50g hydrogenated bisphenol A, 15g neopentyl glycol, 16g 1,3-butanediol, 100g fumaric anhydride, 115g cyclohexanedicarboxylic acid, 23g hydrogenated terpene Maleic anhydride and 10g SO 4 2- / ZrO 2 Type solid acid catalyst is put into there-necked flask, be warming up to 160 ℃ of insulation for 1 hour, be warming up to 170 ℃ of insulation for 1 hour, then be warming up to 180 ℃ of insulation 1.5 hours and measure the acid value of reactant 155mgKOH / g, then add 1-( 20g of 2-hydroxyethyl) pyrrole, react at 160-180°C for 1 hour, heat up to 195-200°C, keep the acid value at 32mgKOH / g after holding for 2 hours, keep at 195-200°C, and steadily increase the vacuum degree to 20 minutes. 450Pa, the acid value of the reactant after maintaining vacuum distillation for 30 minutes was 13 mgKOH / g.

[0050] The above-mentioned ester polymer was cooled to 130°C and added with 1g of polymerization inhibitor hydroquinone, mixed for 5 minutes, and discharg...

Embodiment 2

[0054] 220g 1,4-cyclohexanedimethanol, 50g hydrogenated bisphenol A, 15g neopentyl glycol, 16g 1,3-butanediol, 100g fumaric anhydride, 115g cyclohexanedicarboxylic acid, 23g hydrogenated terpene horse lyric anhydride and 10g SO 4 2- / ZrO 2 Type solid acid catalyst is put into the three-necked flask, heated to 160 ℃ and kept for 1 hour, heated to 170 ℃ and kept for 1 hour, then heated to 180 ℃ and kept for 1.5 hours, and the acid value of the reactant is measured to be 155 mgKOH / g, and then 20 grams of 1 -(2-Hydroxyethyl)pyrrole, react at 160-180°C for 1 hour, raise the temperature to 195-200°C, keep the acid value at 32 mgKOH / g after holding for 2 hours, keep the temperature at 195-200°C, and steadily increase the vacuum degree within 20 minutes The acid value of the reactant was 13 mgKOH / g after maintaining the vacuum distillation for 30 minutes to 450 Pa.

[0055] The above-mentioned ester polymer was cooled to 130 ° C, and 1 g of polymerization inhibitor hydroquinone was...

Embodiment 3

[0057] 220g 1,4-cyclohexanedimethanol, 50g hydrogenated bisphenol A, 15g neopentyl glycol, 16g 1,3-butanediol, 100g fumaric anhydride, 115g cyclohexanedicarboxylic acid, 23g hydrogenated terpene horse The acid anhydride was dropped into the three-necked flask, heated to 160 °C and incubated for 1 hour, warmed to 170 °C and incubated for 1 hour, then warmed to 180 °C and incubated for 1.5 hours and the acid value of the reactant was measured 155mgKOH / g, then added 20 grams of 1-( 2-Hydroxyethyl)pyrrole, react at 160-180°C for 1 hour, heat up to 195-200°C, keep the acid value at 32mgKOH / g after 2 hours, keep at 195-200°C, and steadily increase the vacuum to 450Pa within 20 minutes , the acid value of the reactant was 13 mgKOH / g after vacuum distillation was maintained for 30 minutes.

[0058] The above-mentioned ester polymer was cooled to 130 ° C, and 1 g of the polymerization inhibitor hydroquinone was added, and after mixing for 5 minutes, 300 g of cross-linking agent (wherei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| volatile matter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com