Environment-friendly non-ironing process for shirt

A technology for shirts and environmental protection, which is applied in the field of environmentally friendly non-ironing technology for shirts. It can solve the problems of increasing the production cost of non-ironing shirts, cumbersome processes, and prolonging the production cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 1, a kind of shirt environmental protection non-ironing process, comprises the following steps:

[0043] Step 1, finishing agent absorption: dissolve the finishing agent and water at a ratio of 1:3, and spray the finishing agent solution evenly on the shirt through the atomizing nozzle;

[0044] Step 2, preliminary drying: put the shirt absorbed with the finishing agent solution into an oven for drying, the drying temperature of the oven is 60-70°C, and dry the shirt until the finishing agent solution does not drip;

[0045] Step 3, three-dimensional shaping: press and shape each part of the shirt at a temperature of 130-150°C until the shirt has a good appearance;

[0046] Step 4, shaping in the drying room: Hang the pressed shirt on a hanger made of heat-resistant material, and put it in the drying room to completely dry the shirt and complete the setting. The drying temperature of the drying room is 160-180°C , the drying time is 4-5min;

[0047] Step 5,...

Embodiment 2

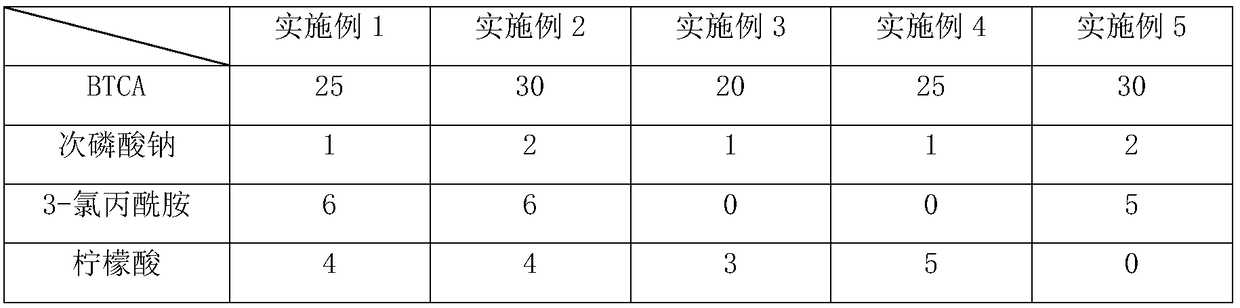

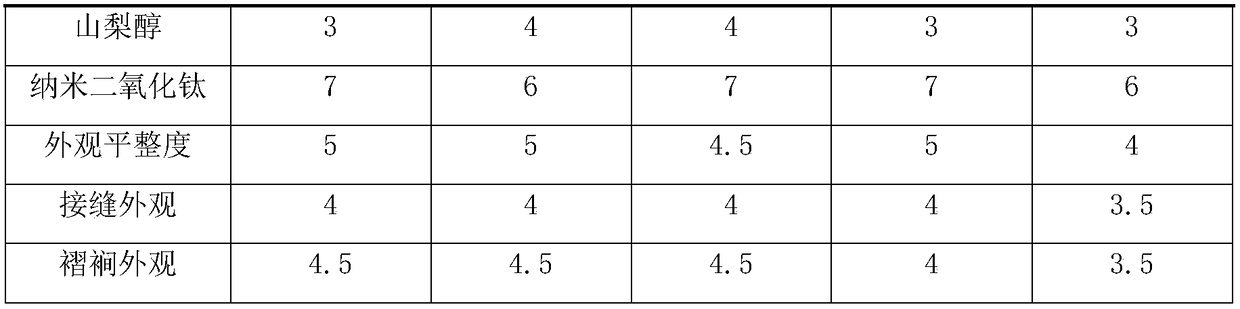

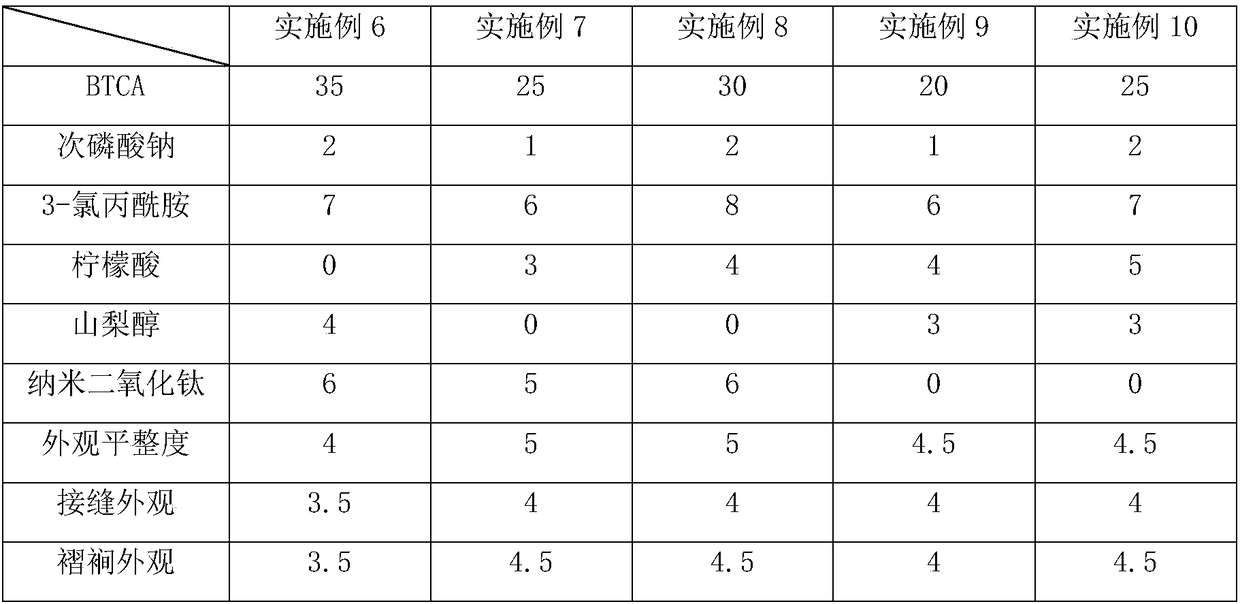

[0049] The difference between Example 2 and Example 1 is that, in parts by weight, the raw material components of the finishing agent are shown in Table 1.

Embodiment 3

[0050] The difference between Example 3 and Example 1 is that, in parts by weight, the raw material components of the finishing agent are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com