Anti-wrinkle dust coat and treatment process thereof

A treatment process and windbreaker technology, which is applied in the field of clothing, can solve the problems of formaldehyde release, etc., and achieve the effect of improving washability and good reducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] An anti-wrinkle windbreaker, which is subjected to anti-wrinkle treatment by a finishing agent. The raw material components of the finishing agent are shown in Table 1 in parts by weight.

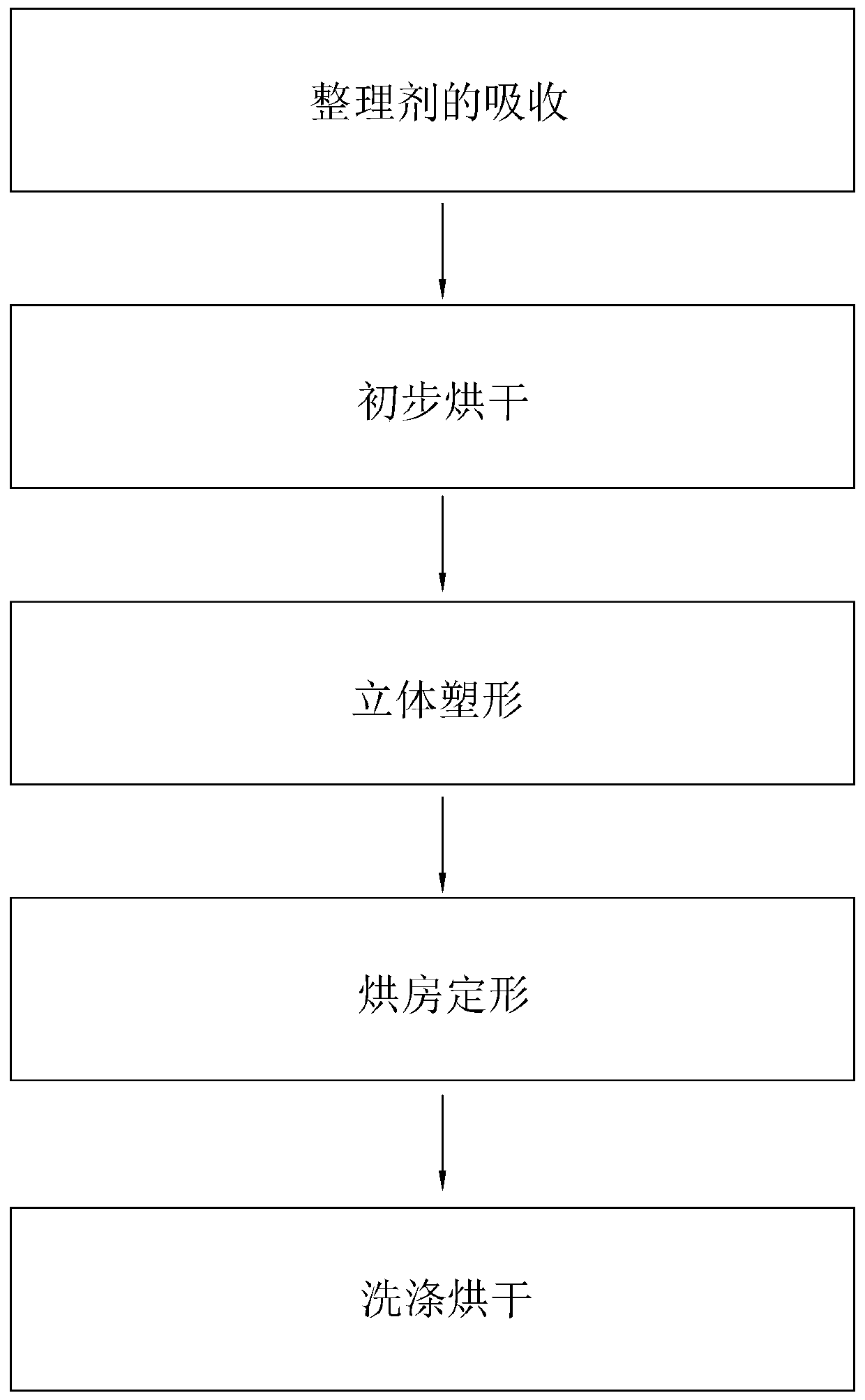

[0051] Wherein, the treatment process of the anti-wrinkle windbreaker includes the following steps:

[0052] Step 1, absorption of the finishing agent: Dilute the finishing agent with water and evenly spray it on the windbreaker;

[0053] Step 2, preliminary drying: bake the windbreaker that has absorbed the finishing agent at 100°C for 2-5 minutes until no water drops;

[0054] Step 3, three-dimensional shaping: press and shape each part of the windbreaker at a temperature of 120°C;

[0055] Step 4, setting the shape in the drying room: push the pressed windbreaker into the drying room to completely dry and set the shape, the drying temperature is 200 ° C, and the drying time is 5 minutes;

[0056] Step 5, washing and drying: cool the completely dried windbreaker, then wash to rem...

Embodiment 2

[0058] An anti-wrinkle windbreaker, which is subjected to anti-wrinkle treatment by a finishing agent. The raw material components of the finishing agent are shown in Table 1 in parts by weight.

[0059] Wherein, the treatment process of the anti-wrinkle windbreaker includes the following steps:

[0060] Step 1, absorption of the finishing agent: Dilute the finishing agent with water and evenly spray it on the windbreaker;

[0061] Step 2, preliminary drying: bake the windbreaker that has absorbed the finishing agent at 90°C for 2-5 minutes until no water drops;

[0062] Step 3, three-dimensional shaping: press and shape each part of the windbreaker at a pressing temperature of 140°C;

[0063] Step 4, setting the shape in the drying room: Push the pressed windbreaker into the drying room to completely dry and set the shape. The drying temperature is 180°C and the drying time is 4 minutes;

[0064] Step 5, washing and drying: cool the completely dried windbreaker, then wash t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com