Composition used in VPI process

A technology of composition and process, applied in the field of resin, to achieve the effect of low viscosity, good cohesiveness, and reduction of residual small molecules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

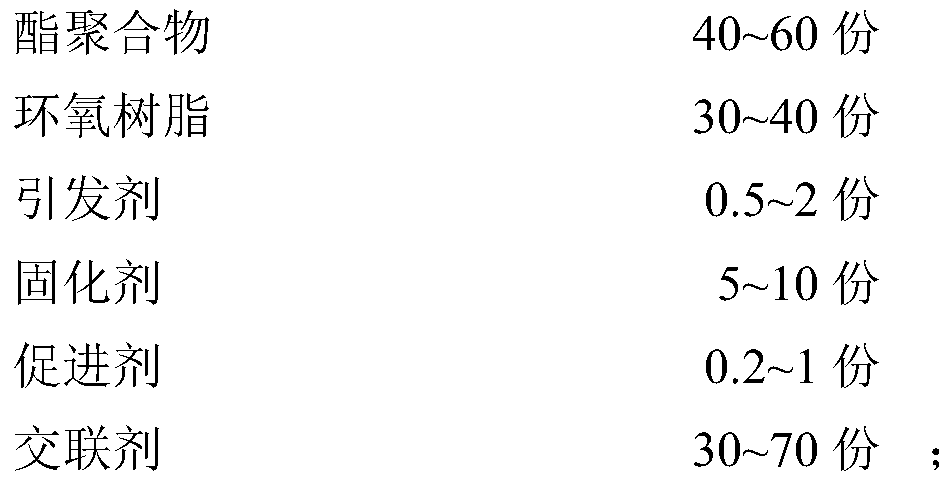

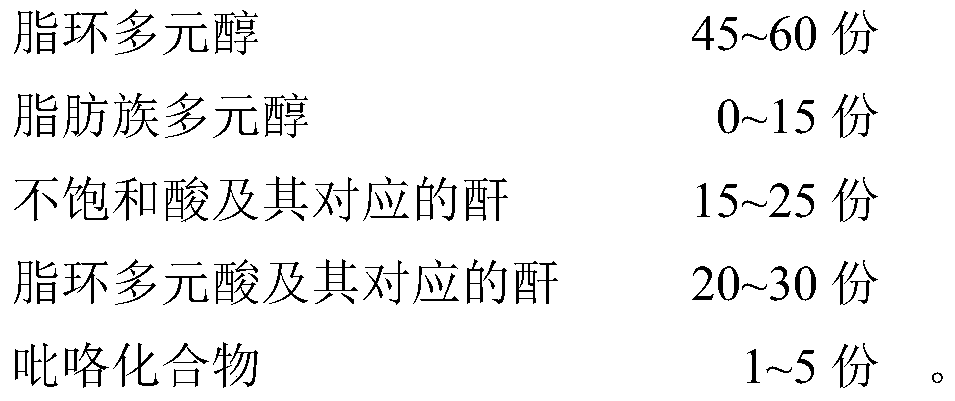

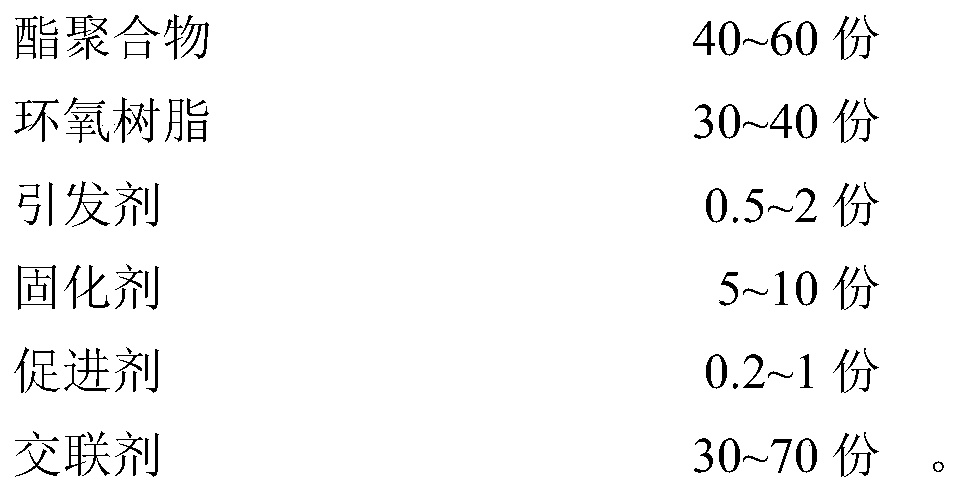

Method used

Image

Examples

Embodiment 1

[0052] 220g 1,4-cyclohexanedimethanol, 50g hydrogenated bisphenol A, 15g neopentyl glycol, 16g 1,3-butanediol, 100g fumaric anhydride, 115g cyclohexanedicarboxylic acid, 23g hydrogenated terpene maleic anhydride and 10 g SO 4 2- / ZrO 2 Type solid acid catalyst into a three-necked flask, heat up to 160°C for 1 hour, heat up to 170°C for 1 hour, then heat up to 180°C for 1.5 hours, then measure the acid value of the reactant to 155mgKOH / g, then add 1-( 2-Hydroxyethyl)pyrrole 20g, react at 160-180°C for 1 hour, heat up to 195-200°C, after 2 hours of heat preservation, the acid value is 32mgKOH / g, keep heat at 195-200°C, and increase the vacuum degree steadily within 20 minutes to 450Pa, the acid value of the reactant after maintaining vacuum distillation for 30 minutes was 13mgKOH / g.

[0053] Cool the above ester polymer to 130°C, add 1g of inhibitor hydroquinone, mix for 5 minutes, and discharge until 300g of crosslinking agent has been added (100g of ethylene glycol dimethac...

Embodiment 2

[0057] 220g1,4-cyclohexanedimethanol, 50g hydrogenated bisphenol A, 15g neopentyl glycol, 16g1,3-butanediol, 100g fumaric anhydride, 115g cyclohexanedicarboxylic acid, 23g hydrogenated terpene Toric anhydride and 10g SO 4 2- / ZrO 2 Type solid acid catalyst into a three-necked flask, heat up to 160°C for 1 hour, heat up to 170°C for 1 hour, then heat up to 180°C for 1.5 hours, then measure the acid value of the reactant to 155 mgKOH / g, then add 20 grams of 1 -(2-Hydroxyethyl)pyrrole, react at 160-180°C for 1 hour, raise the temperature to 195-200°C, after 2 hours of heat preservation, the acid value is 32mgKOH / g, keep heat at 195-200°C, and increase the vacuum degree steadily within 20 minutes To 450Pa, the acid value of the reactant was 13mgKOH / g after maintaining the vacuum distillation for 30 minutes.

[0058] Cool the above-mentioned ester polymer to 130° C., add 1 g of inhibitor hydroquinone, mix for 5 minutes, and discharge until 300 g of crosslinking agent (100 g of e...

Embodiment 3

[0062] 220g1,4-cyclohexanedimethanol, 50g hydrogenated bisphenol A, 15g neopentyl glycol, 16g1,3-butanediol, 100g fumaric anhydride, 115g cyclohexanedicarboxylic acid, 23g hydrogenated terpene To acid anhydride is put into a three-necked flask, heated up to 160°C for 1 hour, heated up to 170°C for 1 hour, then heated up to 180°C for 1.5 hours, then measured the acid value of the reactant to be 155 mgKOH / g, then added 20 grams of 1-( 2-Hydroxyethyl)pyrrole, react at 160-180°C for 1 hour, heat up to 195-200°C, after 2 hours of heat preservation, the acid value is 32mgKOH / g, keep heat at 195-200°C, and steadily increase the vacuum degree to 450Pa within 20 minutes , the acid value of the reactant was 13mgKOH / g after maintaining the vacuum distillation for 30 minutes.

[0063] Cool the above-mentioned ester polymer to 130° C., add 1 g of inhibitor hydroquinone, mix for 5 minutes, and discharge until 300 g of crosslinking agent (100 g of ethylene glycol dimethacrylate, 70 g of 1,6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com