A kind of composite polymer sludge dewatering agent and preparation method thereof

A sludge dewatering agent and composite polymer technology, applied in the direction of dehydration/drying/concentrating sludge treatment, can solve the problems of uncontrollable molecular structure, few industrialized products, poor solubility, etc. Low toxicity and good treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

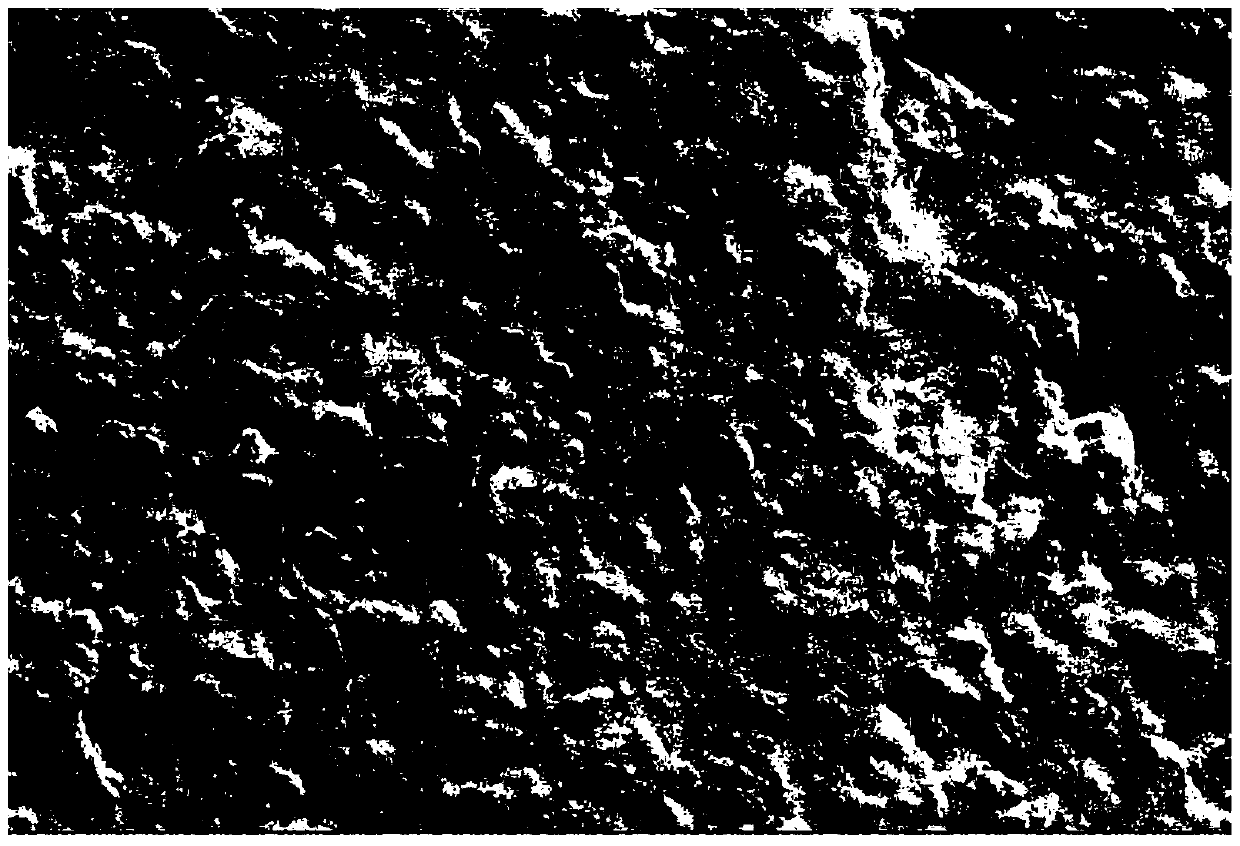

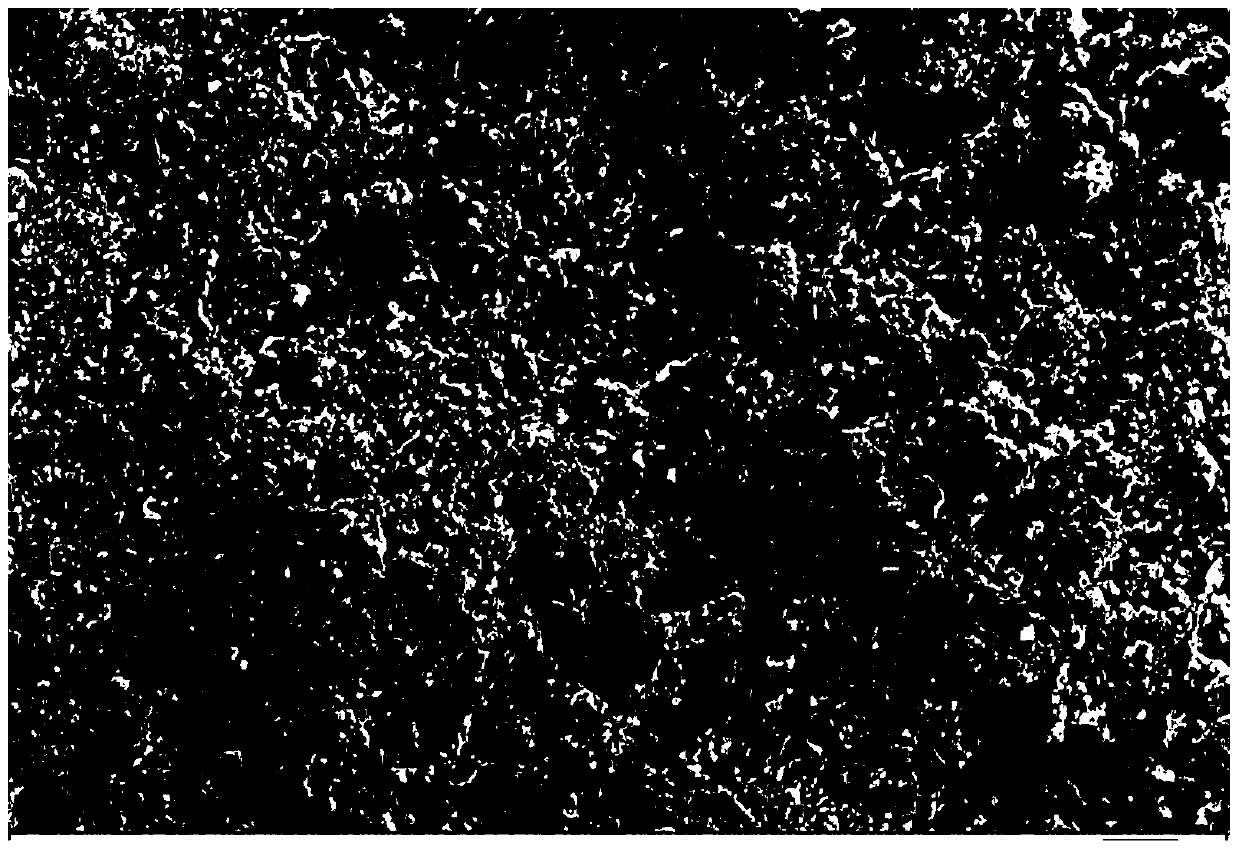

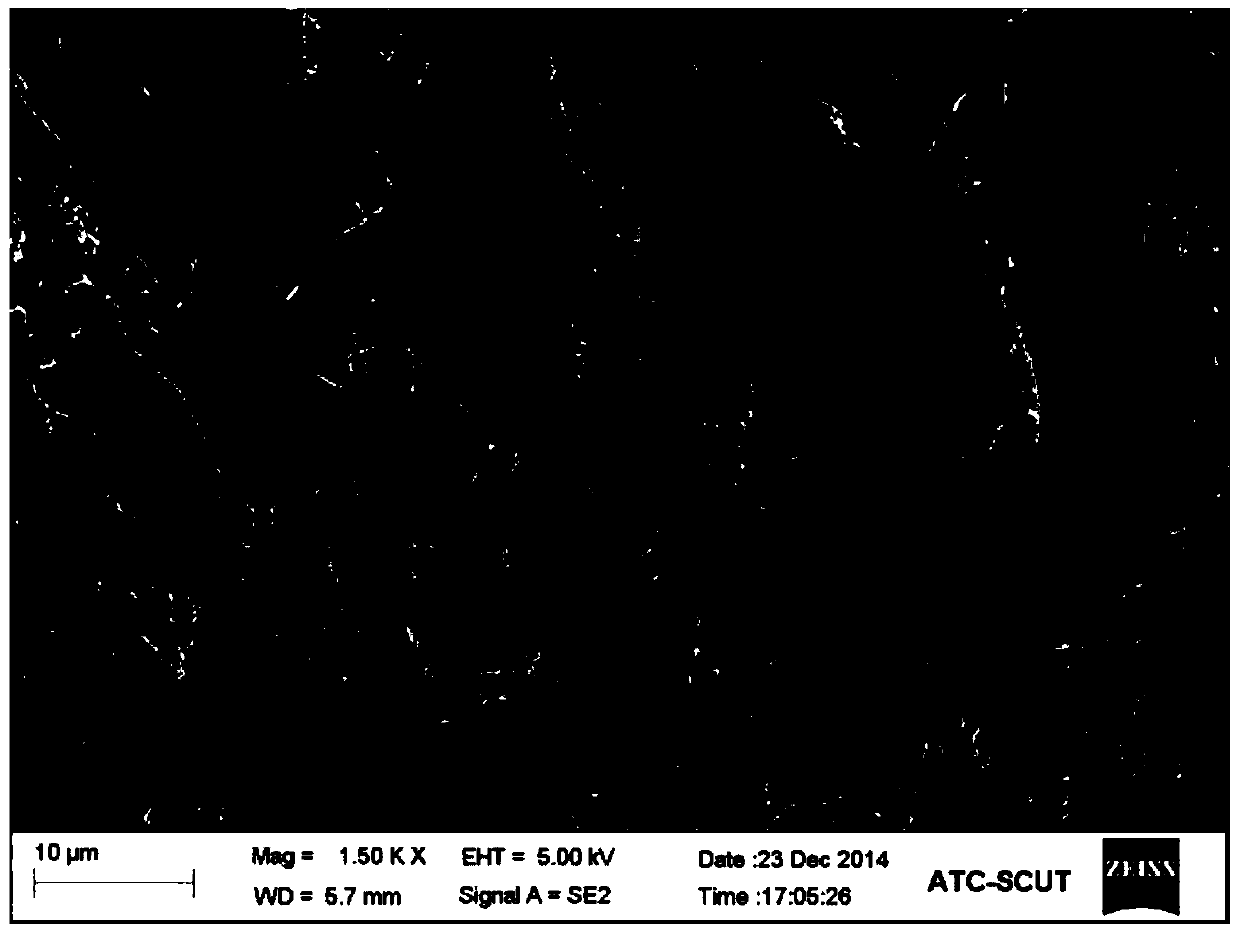

Image

Examples

Embodiment 1

[0033] (1) 0.76kg methyl acrylate (industrial refined liquid, Jiangxi Changjiu Company, the same below) was made into 7.6kg aqueous solution and 0.08kg 2-acrylamido-2-methylpropanesulfonic acid (concentration Be 60% industrial refining solution, U.S. Lubrizol Company, the same below) is made into 0.48kg aqueous solution, 0.26kg acryloyloxyethyltrimethyl ammonium chloride (concentration is the industrial refining solution of 70%, Jiangsu Nantian Company, The same below) was made into 1.8kg aqueous solution. Add the above three aqueous solutions into an enamel reaction kettle with a stirrer and a heating jacket, adjust the pH to 4 with 1% mass fraction hydrochloric acid and sodium hydroxide, start stirring, and pass nitrogen to remove oxygen;

[0034] (2) Add respectively 0.0035kg ammonium persulfate, 0.003kg sodium bisulfite, 0.003kg azobisisobutylamidine hydrochloride (industrial refined crystallization, Guangzhou Chuangyuan Company, the same below), 0.002kg kg of EDTA-2Na, t...

Embodiment 2

[0039] (1) 0.73kg methyl methacrylate (industrial refining liquid) was made into 7.3kg aqueous solution, 0.13kg 2-acrylamido-2-methylpropanesulfonic acid (60% industrial refining liquid) with deionized water solution) was made into 0.8kg aqueous solution, and 0.22kg acryloyloxyethyltrimethylammonium chloride (concentration is 70% industrially refined solution) was made into 1.5kg aqueous solution. Add the above three aqueous solutions into an enamel reaction kettle with a stirrer and a heating jacket, adjust the pH to 3 with 1% hydrochloric acid and sodium hydroxide, start stirring, and pass nitrogen to remove oxygen;

[0040] (2) Add 0.004kg potassium persulfate, 0.002kg sodium sulfite, 0.005kg azobisimidazolinyl propane dihydrochloride, 0.004kg EDTA-2Na respectively to the solution of the reactor, and control the reaction temperature to be 30°C;

[0041] (3) When the reaction is carried out for 3 hours, add 0.1 kg of ferric sulfate, fully stir, continue to pass nitrogen gas fo...

Embodiment 3

[0043] (1) 0.68kg ethyl acrylate (industrial refined liquid) is made into 6.8kg aqueous solution respectively with deionized water, 0.14kg acrylic acid (concentration is the industrial refined solution of 60%) is made into 0.82kg aqueous solution, 0.33kg dimethyl dimethicone Allyltrimethylammonium chloride (concentration is 70% industrial refining solution) is made into 2.3kg aqueous solution. Add the above three aqueous solutions into an enamel reaction kettle with a stirrer and a heating jacket, adjust the pH to 5 with 1% hydrochloric acid and sodium hydroxide, start stirring, and pass nitrogen to remove oxygen;

[0044] (2) In the solution of reactor, add 0.004kg potassium persulfate respectively, 0.005kg sodium bisulfite, 0.004kg azobisisobutylamidine hydrochloride, add the EDTA-2Na of 0.004kg again, control reaction temperature to be 45 ℃, to promote chain initiation and chain growth reactions;

[0045] (3) When the reaction is carried out for 4 hours, add 0.2 kg of poly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com