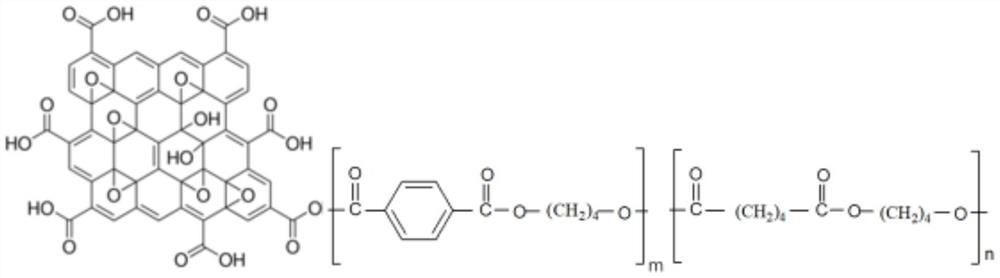

A kind of graphene in-situ polymerization biodegradable copolyester and its preparation method and application

A technology of biodegradation and in-situ polymerization, which is applied in the direction of chemical/physical/physicochemical processes of applied energy, can solve problems such as unsuitable biodegradation fields, and achieve adjustable biodegradation time, narrow molecular weight distribution, and better physical properties. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

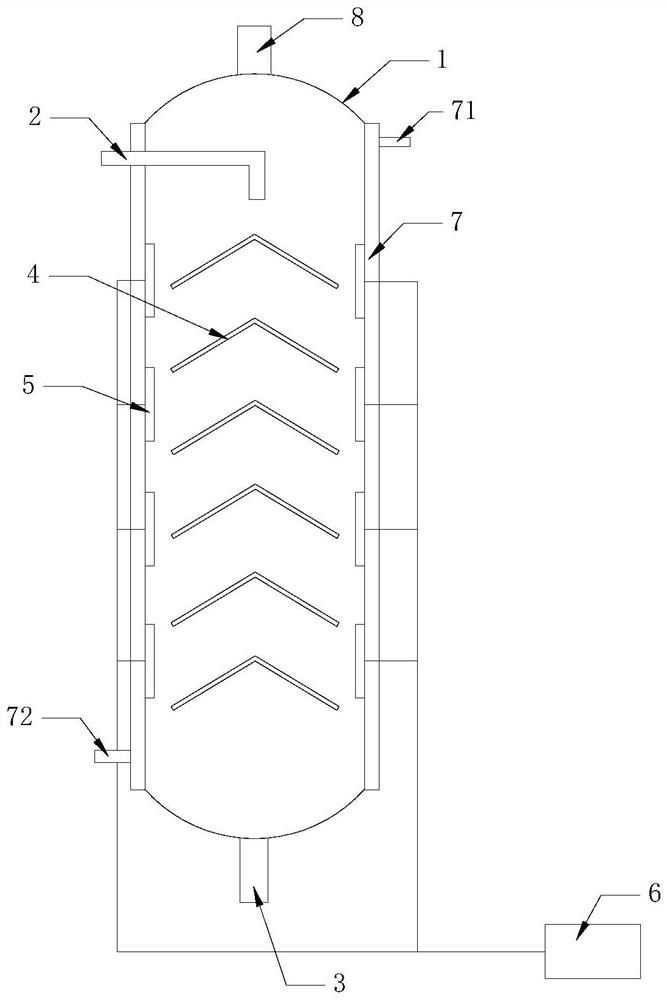

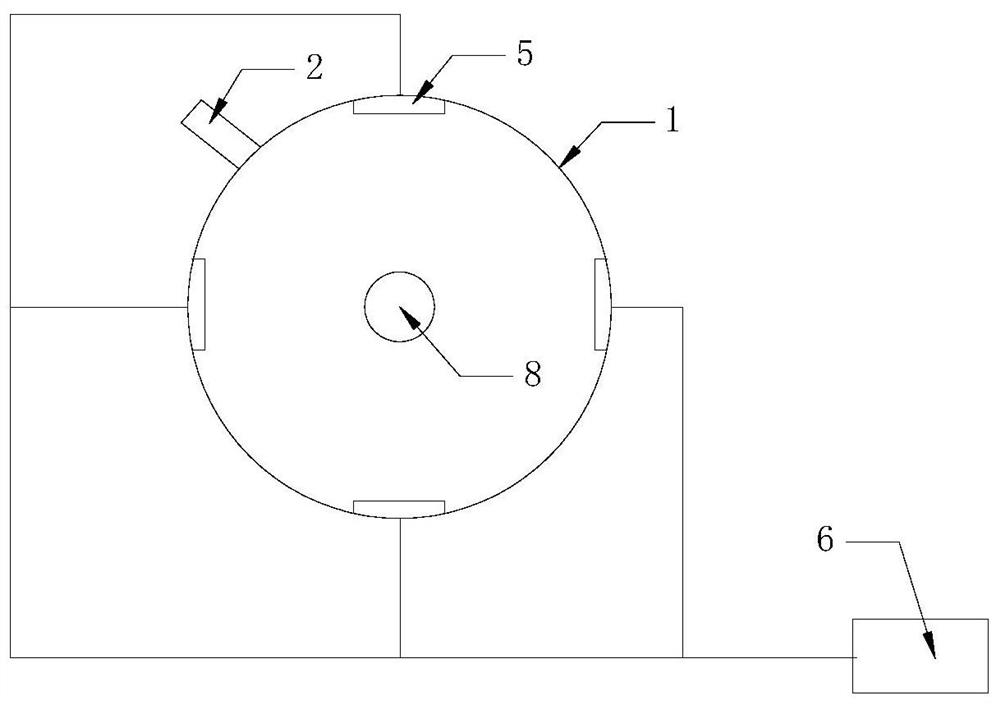

[0031] This embodiment discloses a tray type continuous esterification reactor, such as Figure 1-2 As shown, it includes a reactor body 1, a material inlet 2, a material outlet 3, a tray 4 and an ultrasonic dispersion part, wherein the material inlet 2 is arranged at the upper end of the side wall of the reactor body 1; the material outlet 3 is arranged at the reactor body 1 The lower end of the gas phase outlet 8 is arranged on the upper end of the reactor body 1, and the tray 4 is arranged in the inner cavity of the reactor body 1, and the cross section of the tray 4 is arranged in an inverted V shape; the ultrasonic dispersion part includes an ultrasonic dispersion probe 5, A number of ultrasonic dispersion probes 5 are arranged on the inner wall of the reactor body 1, and the ultrasonic dispersion probes 5 are arranged in cooperation with the tray 4 so that the material entering from the material inlet 2 falls on the center directly above the tray 4, and the material flows...

Embodiment 2

[0036] Embodiment 2: a kind of preparation method of graphene in-situ polymerization biodegradable copolyester:

[0037] S1. Graphene dispersion: add graphene to an appropriate amount of diol, and apply a high-speed stirrer and an ultrasonic disperser to perform pre-dispersion treatment at the same time to obtain a graphene dispersion liquid. The graphene content in the graphene dispersion liquid is 4-8wt %.

[0038] S2. Auxiliary configuration: Add catalysts, antioxidants, stabilizers, lubricants and other auxiliaries to an appropriate amount of glycol, and perform pre-dispersion treatment with a high-speed agitator to obtain an auxiliary agent dispersion. The additive content is 5-10wt%.

[0039] S3. Beating: Add two kinds of dibasic acids and one kind of dibasic alcohol in a certain ratio into the beating kettle, maintain the temperature of the beating kettle at 65-75°C, stirrer speed at 100-120r / min, beating for 1 hour, and then add the step (a) and the graphene dispersi...

Embodiment 3

[0047] Example 3: Characterization

[0048] This embodiment tests the graphene in situ polymerization biodegradable copolyester obtained in Example 1, wherein the test method is as follows:

[0049] 1. Biodegradation rate, the test method is: GB / T 20197-2013

[0050] 2. Surface resistance value, the test method is: GB / T 1410-2006

[0051] 3. Antibacterial performance, the test method is: QB / T 2591-2003

[0052] 4. Water vapor transmission rate, the test method is: GB / T 1037-1988

[0053] 5. Tensile strength, the test method is: GB / T 1040-2006

[0054] 6. Elongation at break, the test method is: GB / T 1040-2006

[0055] Table 1 Performance test results of graphene in situ polymerization biodegradable copolyester

[0056]

[0057] According to the data in Table 1 above, it can be seen that the biodegradation rate of the graphene in-situ polymerization biodegradable copolyester obtained in this application can reach more than 95%, and it has good electrical conductivity, s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com