Allyl polyglycol ether type polycarboxylic acid series dehydragent and preparation method thereof

A polyglycol ether and polycarboxylic acid-based technology, which is applied in the field of chemical raw material preparation, can solve the problems of insufficient water reduction rate, poor adaptability and high cost, and achieve improved strength and durability, good slump retention, The effect of high water reduction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

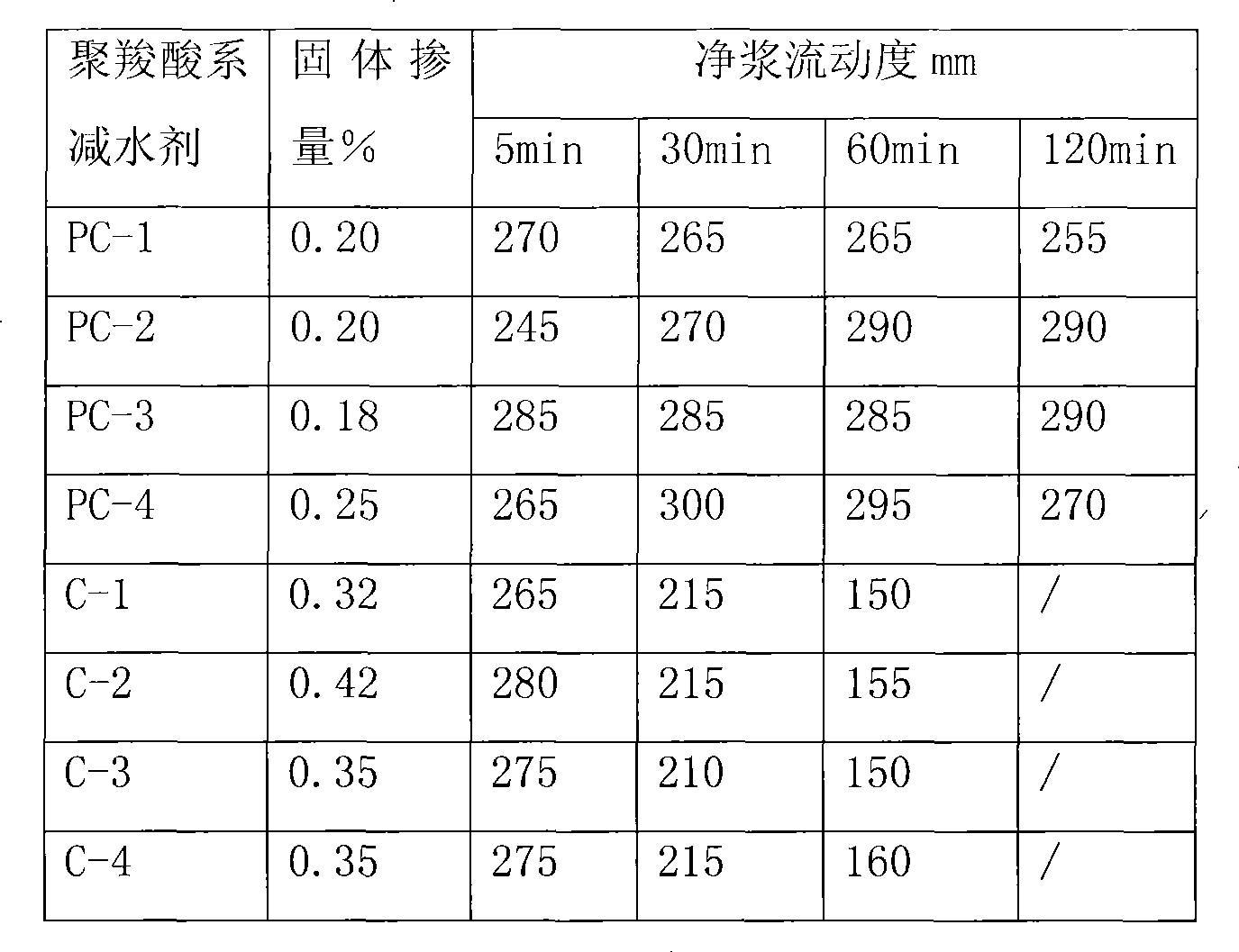

Embodiment 1

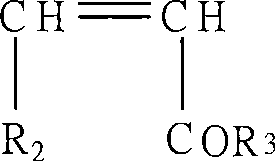

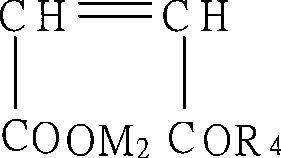

[0042] This embodiment provides an allyl polyglycol ether type polycarboxylate water reducer with super strong dispersing effect. Compared with the water-reducing agent, the conversion rate of the reaction product of the water-reducing agent is high, and it can show high dispersibility with a small amount of addition. Especially in the field of high water-reducing rate, it has excellent performance when applied in concrete. The water-reducing agent It is a polymer formed by copolymerization of the following components in an aqueous solution using a redox initiation system. The polymer water reducer contains:

[0043] Unsaturated polyoxyalkylene ether monomer (a) 30-50% (accounting for the percentage of total polymer weight)

[0044] Unsaturated monocarboxylic acid and its derivatives monomer (b) 5-20% (accounting for the percentage of the total weight of the polymer)

[0045] Unsaturated dibasic carboxylic acid (c) 1~20% (accounting for the percentage of polymer gross weight)...

Embodiment 2

[0067] This embodiment provides an allyl polyglycol ether type polycarboxylic acid-based water reducer. The amounts of the following components used to prepare the water reducer are by weight, including:

[0068] 1200g Allyl polyglycol ether 1200

[0069] 105g monomer of acrylic acid

[0070] 49g maleic anhydride

[0071] 25g sodium methacrylate

[0072] 1095g deionized water (add in two times, add 700g for the first time, add 395g and 105g of acrylic acid monomer for the second time to form an aqueous solution of acrylic acid monomer)

[0073] 30g 27.5% hydrogen peroxide

[0074] 250g of 5% sodium hydroxymethyl bisulfite solution

[0075] 360g 30% NaOH;

[0076]Add 1200g allyl polyglycol ether 1200, 700g deionized water, 49g maleic anhydride, 25g sodium methacrylate, 30g in a glass flask equipped with a stirrer, thermometer, dropping device, and reflux cooler Mix hydrogen peroxide with a concentration of 27.5%, and after heating up to 65°C, add dropwise monomer aqueous ...

Embodiment 3

[0078] This embodiment provides an allyl polyglycol ether type polycarboxylic acid-based water reducer. The amounts of the following components used to prepare the water reducer are by weight, including:

[0079] 2100g Allyl polyglycol ether 2400

[0080] 129g methacrylic acid

[0081] 249g Polyethylene glycol 400 monoester maleate (98:400)

[0082] 1771g deionized water (add 1300g for the first time in two uses, and the remaining 471g deionized water is used to mix with 129g methacrylic acid to form a methacrylic acid solution)

[0083] 30g of 27.5% hydrogen peroxide

[0084] 250g of 5% L-ascorbic acid solution

[0085] 360g of 30% NaOH

[0086] Add 2100g allyl polyethylene glycol ether 2400, 1300g deionized water, 249g polyethylene glycol maleate 400 monoester (98: 400), 30g concentration is 27.5% hydrogen peroxide, after being warmed up to 65 ℃, dropwise in above-mentioned glass flask simultaneously in 3 hours the monomer aqueous solution that has mixed 129g methacryli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com