Marine concrete

A technology of marine concrete and cementitious materials, which is applied in the field of construction concrete and can solve the problems of low anti-corrosion performance and poor durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

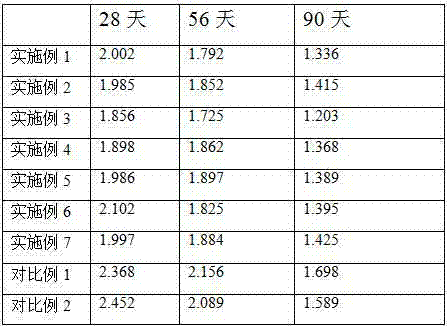

Examples

Embodiment Construction

[0011] 1. Preparation of raw materials

[0012] 1. Cement

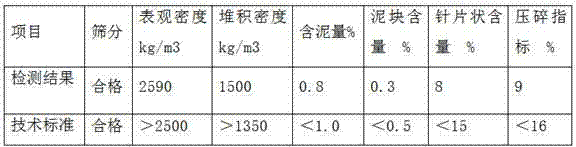

[0013] Guangxi Fusui Xinning Conch P.O42.5 Ordinary Portland Cement is used, and its main testing indicators are shown in Table 1

[0014] Table 1 P.O42.5 cement technical indicators

[0015]

[0016] The fineness of cement should not be too fine, otherwise it will cause problems of excessive heat of hydration and increased water demand, which will cause a decrease in the crack resistance of concrete. At the same time, considering the low heat of hydration requirements of the large-volume concrete of the tower base, the strength grade should be selected. 42.5 ordinary Portland cement, in order to avoid the occurrence of alkali-aggregate reaction, the alkali content in the cement is ≤0.6%. In order to make the cement have good compatibility with the high-efficiency water-reducing agent and give full play to the water-reducing rate of the high-efficiency water-reducing agent, it is advisable to control the C3A cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Maximum particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com