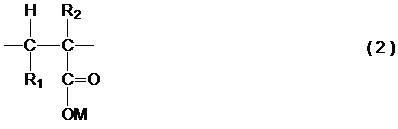

Polyether amine modified polycarboxylic water reducer and preparation method thereof

A technology of polycarboxylate and polyetheramine, applied in the field of concrete admixtures, can solve problems such as difficult control and harsh conditions, and achieve the effects of improving efficiency, high concrete water reduction rate and shortening reaction time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Add 100.0 g of B-2, 50.0 g of itaconic acid and 780.0 g of water into a 2000 ml four-necked flask equipped with a stirrer, a thermometer, and a dropping device, and stir to raise the temperature to 80°C. At the same time, 200.0g of ammonium persulfate aqueous solution (obtained by dissolving 20.0g of ammonium persulfate in 180.0g of water), 20.0g of 3-mercaptopropionic acid and 850.0g of B-1 were added dropwise, and the dropping time was controlled at 180 minutes and 150 minutes respectively. And 150 minutes, the reaction temperature is controlled at 78~82 ℃. After the dropwise addition, keep the temperature at 78-82°C for about 60 minutes to complete the polymerization reaction to obtain a polycarboxylic acid copolymer, which is denoted as PC-1, and its weight-average molecular weight is 3800 by GPC test.

[0051] Add 200.0g of polycarboxylic acid copolymer PC-1 and 957.95g of A-1 into a 2000ml four-neck flask equipped with a stirrer, thermometer, condenser and vacuum ...

Embodiment 2

[0053] Add 200.0 g of itaconic acid and 775.0 g of water into a 2000 ml four-necked flask equipped with a stirrer, a thermometer, and a dropping device, and stir to raise the temperature to 95°C. At the same time, 200.0g of ammonium persulfate aqueous solution (obtained by dissolving 20.0g of ammonium persulfate in 180.0g of water), 25.0g of 3-mercaptopropionic acid and 850.0g of B-3 were added dropwise, and the dropping time was controlled at 210 minutes and 180 minutes respectively. And 180 minutes, the reaction temperature is controlled at 78~82 ℃. After the dropwise addition, keep the temperature at 78-82°C for about 60 minutes to complete the polymerization reaction to obtain a polycarboxylic acid copolymer, which is denoted as PC-2, and its weight-average molecular weight is 3100 by GPC test.

[0054] Add 200.0g of polycarboxylic acid copolymer PC-2 and 517.5g of A-2 into a 2000ml four-neck flask equipped with a stirrer, thermometer, condenser and vacuum receiving device...

Embodiment 3

[0056] Add 400.0 g of itaconic acid and 780.0 g of water into a 2000 ml four-necked flask equipped with a stirrer, a thermometer, and a dropping device, and stir to raise the temperature to 52°C. At the same time, 200.0g of sodium persulfate aqueous solution (obtained by dissolving 20.0g of sodium persulfate in 180.0g of water), 20.0g of 3-mercaptopropionic acid and 600.0g of B-1 were added dropwise, and the dropping time was controlled at 210 minutes and 180 minutes respectively. And 180 minutes, the reaction temperature is controlled at 50~54 ℃. After the dropwise addition, keep the temperature at 50-54°C for about 60 minutes to complete the polymerization reaction to obtain a polycarboxylic acid copolymer, which is denoted as PC-3, and its weight-average molecular weight is 3400 by GPC test.

[0057] Add 200.0g of polycarboxylic acid copolymer PC-3 and 544.9g of A-3 into a 2000ml four-neck flask equipped with a stirrer, thermometer, condenser and vacuum receiving device, gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com