Feeding-controllable water absorbing resin particle production system

A production system and water-absorbent resin technology, applied in the field of water-absorbent resin granule production system, can solve problems such as unsatisfactory process requirements, threats to workers’ health, and low accuracy of feeding frequency, and achieve manpower saving, accurate feeding number and frequency, and accurate feeding controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

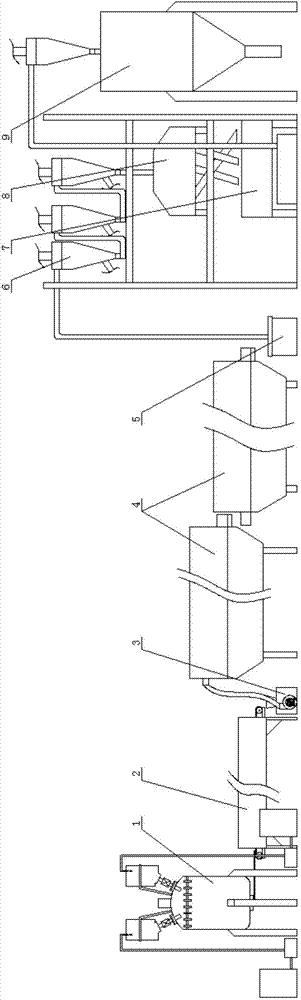

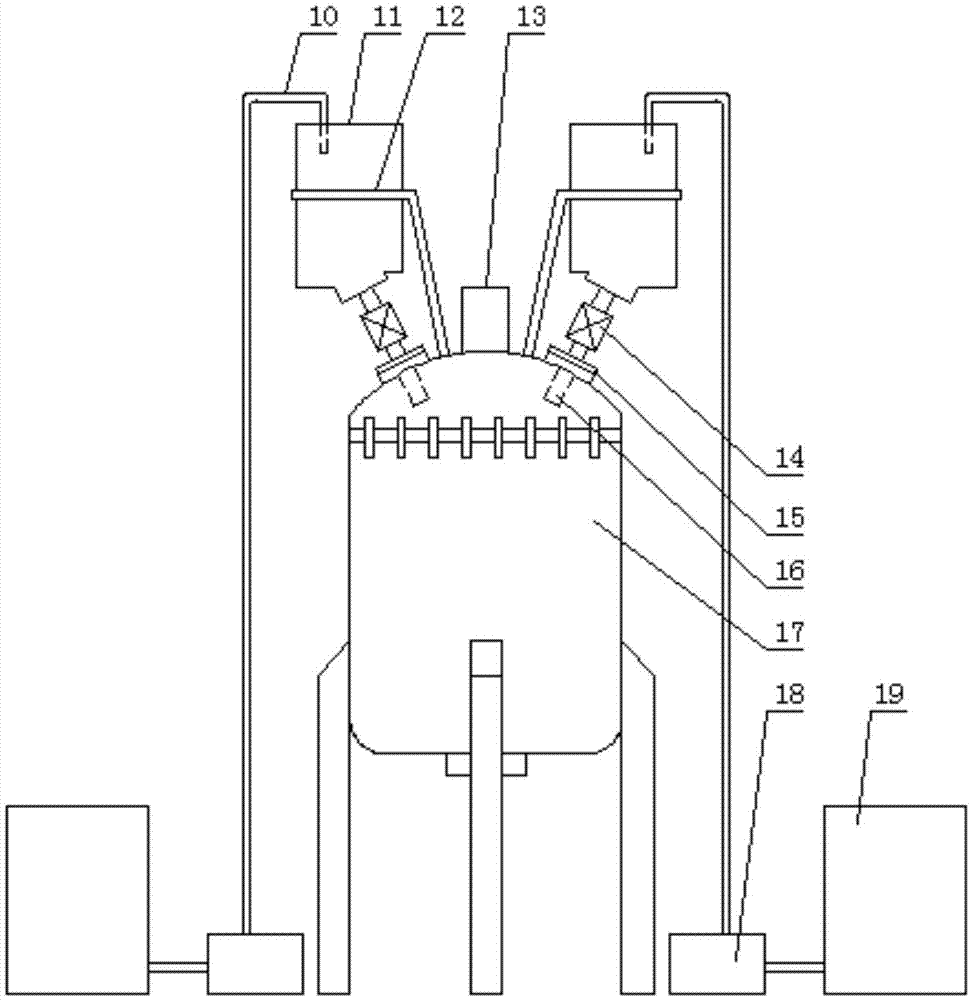

[0016] A water-absorbent resin particle production system with controllable feeding, which is composed of a reactor 1, a polymerization device 2, a colloid mill 3, a dryer 4, a material tank 5, a separator 6, a screening machine 8, a pulverizer 7 and a material bin 9, Its innovation is that the reaction kettle is composed of a kettle body 17 and a controllable feeding mechanism, and the controllable feeding mechanism is composed of a sealing cover 15, a feeding pipe 16, a hydraulic control valve 14, a feeding tank 11, and a mounting frame 12 , a feeding pipe 10, a material pump 18 and a raw material barrel 19. Sealing covers are installed on the two feeding ports of the reactor body, and one end of the feeding pipe passes through the sealing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com