Cell feeding device of solar cell welding machine

A solar cell and welding machine technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of low efficiency of solar cell feeding and manual replacement of material boxes, and achieve easy removal, improved efficiency, and improved The effect of capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

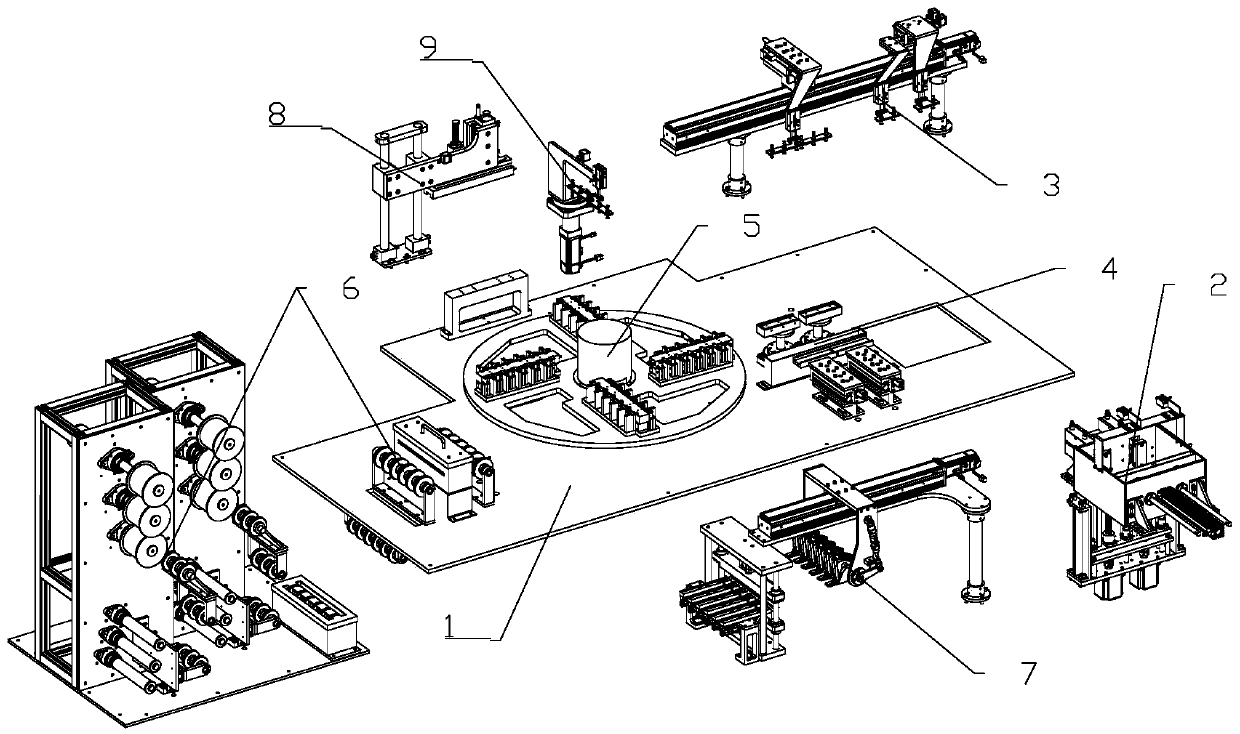

[0020] Such as figure 1 A solar battery welding machine shown includes a frame 1 and a battery feeding device 2 installed on the frame 1, a battery handling device 3, a waste material removal device 4, a turntable jig 5, and a welding strip flux coating device 6 , welding ribbon fixed-length feeding device 7, welding device 8 and unloading device 9; the battery feeding device 2 and the waste rejecting device 4 are arranged side by side, and the battery handling device 3 is located between the battery feeding device 2 and the waste rejecting device 4 Above, the battery handling device 3 is connected with the turntable jig 5; the welding ribbon fixed-length feeding device 7 is located at the discharge end of the welding ribbon flux coating device 6, and the welding ribbon fixed-length feeding device 7 is connected to the turntable jig 5 Connection; the welding device 8 and the blanking device 9 are located on the outer periphery of the turntable jig 5 and correspond to different...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com