Modified wash oil coal water slurry additive and preparing method thereof

A technology of oil-water coal slurry and additives, applied in the petroleum industry, liquid carbon-containing fuel, fuel, etc., can solve the problems of large environmental pollution and low fuel utilization rate, and achieve simple production process, reduce raw material cost, and non-polluting production process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

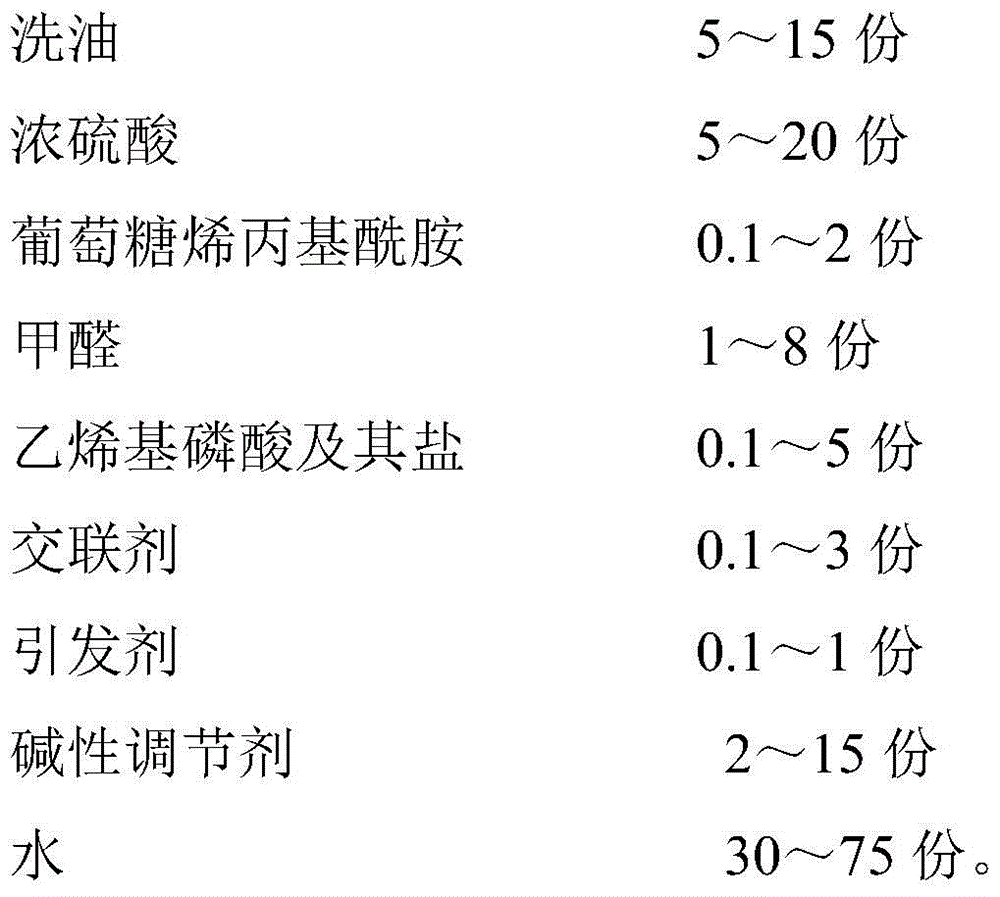

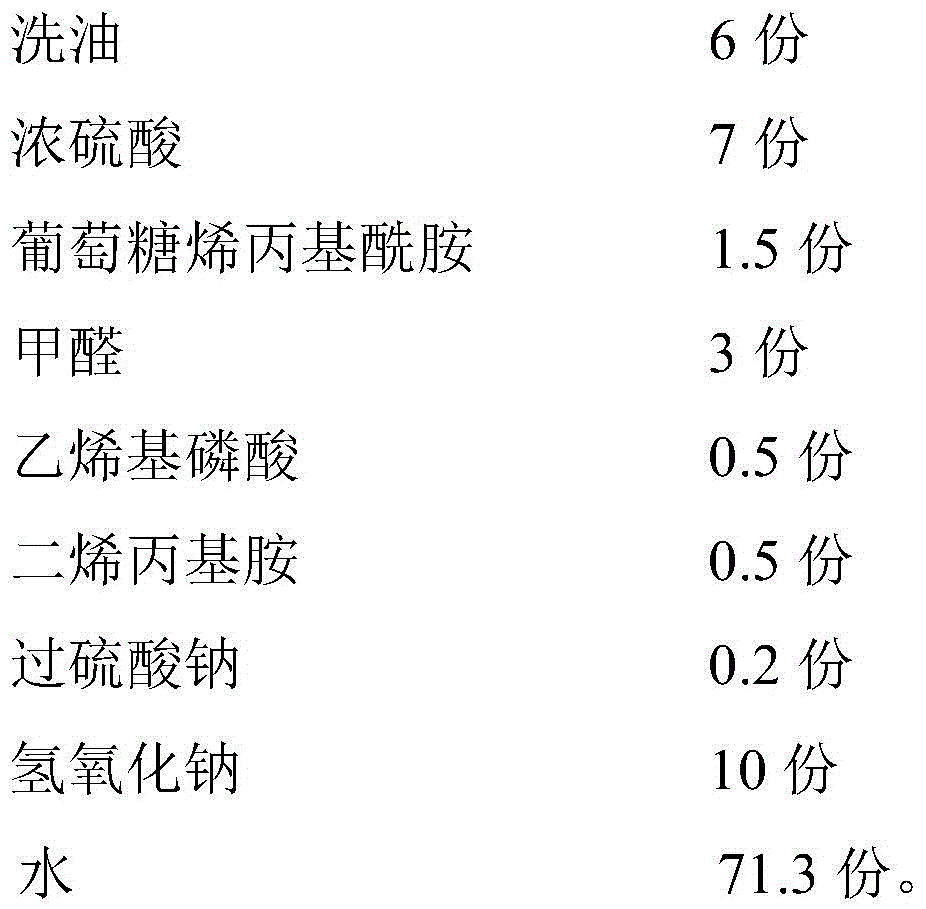

[0025] A modified oil-washing coal-water slurry additive is made of the following raw material components in proportions by weight:

[0026]

[0027] Its preparation method is realized through the following steps:

[0028] (1) Add 6 parts of washing oil to the reaction kettle and heat it up. After the temperature rises to 115°C, stop heating and start stirring. At the same time, add 7 parts of concentrated sulfuric acid to the kettle, and keep warm for 2.5 hours after adding;

[0029] (2) Add 0.5 parts of glucose allylamide, and start to drop 3 parts of formaldehyde solution after cooling the system to 105°C; the dropping time is 2 hours, and the temperature is controlled at 108°C;

[0030] (3) Then add 0.5 part of vinylphosphoric acid, 0.2 part of diallylamine, start dripping the sodium persulfate solution that mass percentage concentration is 2% after adding, this sodium persulfate solution is made of 0.2 part of sodium persulfate It is formulated with 9.8 parts of water...

Embodiment 2

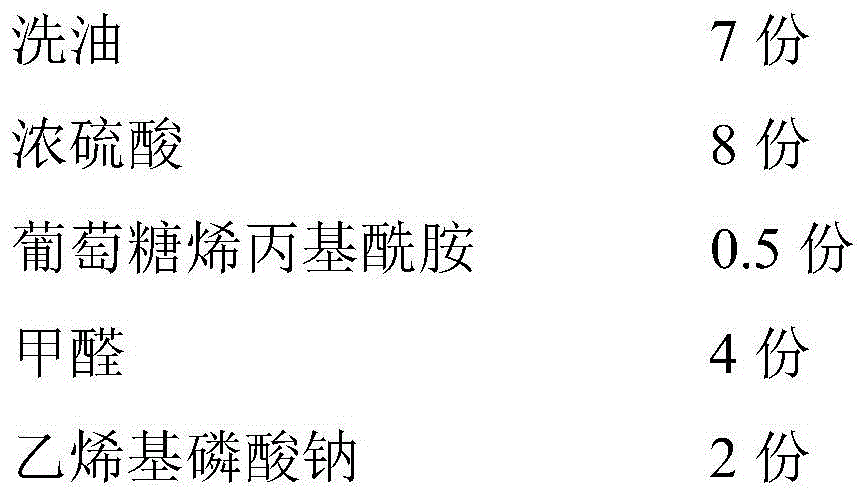

[0033] A modified oil-washing coal-water slurry additive is made of the following raw material components in proportions by weight:

[0034]

[0035]

[0036] Its preparation method is realized through the following steps:

[0037] (1) Add 7 parts of washing oil to the reaction kettle and heat it up. After the temperature rises to 118°C, stop heating and start stirring. At the same time, add 8 parts of concentrated sulfuric acid to the kettle, and keep warm for 2.5 hours after adding;

[0038] (2) Add 0.5 parts of glucose allyl amide, and start to drop 4 parts of formaldehyde solution after cooling the system to 108°C; the dropping time is 2.5 hours, and the temperature is controlled at 108°C;

[0039] (3) Then add 2 parts of sodium vinyl phosphate, 1 part of diallylamine, start dripping the ammonium persulfate solution that the mass percent concentration is 5% after adding, this ammonium persulfate solution is made of 0.5 part of persulfuric acid Ammonium and 9.5 parts...

Embodiment 3

[0042] A modified oil-washing coal-water slurry additive is made of the following raw material components in proportions by weight:

[0043]

[0044] Its preparation method is realized through the following steps:

[0045] (1) Add 8 parts of washing oil to the reaction kettle and heat it up. After the temperature rises to 120°C, stop heating and start stirring. At the same time, add 15 parts of concentrated sulfuric acid to the kettle, and keep warm for 2 hours after adding;

[0046] (2) Add 0.5 parts of glucose allyl amide, and start to drop 5 parts of formaldehyde solution after cooling the system to 110°C; the dropping time is 2.5 hours, and the temperature is controlled at 108°C;

[0047] (3) Then add 2 parts of vinyl phosphate potassium, 1 part of triallylamine, after adding, start to add dropwise the ammonium persulfate solution that the mass percent concentration is 5%, and this ammonium persulfate solution consists of 0.5 part of persulfuric acid Ammonium and 9.5 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com