Chitosan sodium sulfonate containing concrete synergist and preparation method thereof

A technology containing sodium chitosan sulfonate and a concrete synergist is applied in the field of concrete-like additives, which can solve the problems of difficulty in ensuring economical efficiency and workability, inability to effectively exert the strength of cement, and difficulty in concrete functioning again. The effect of pollution-free and clean production process, saving cement consumption and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

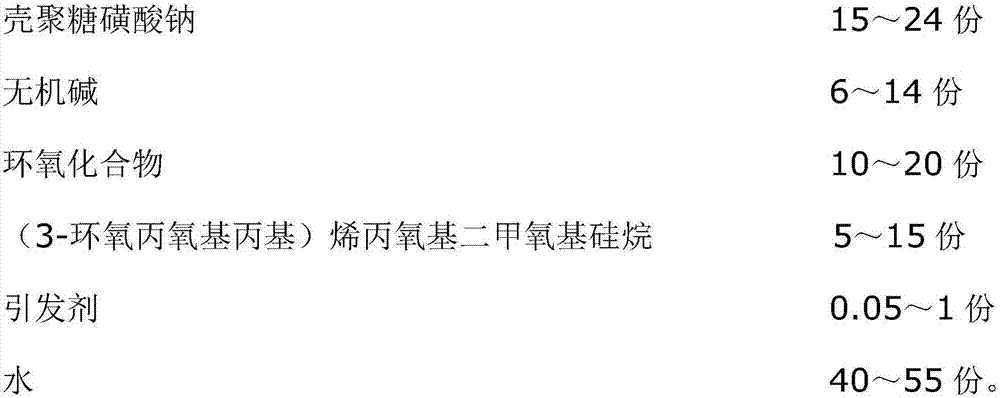

[0045] In the present embodiment, the chitosan derivative concrete synergist is made of the following raw material components in parts by weight:

[0046]

[0047] The concrete preparation method of above-mentioned synergist, realizes by following steps:

[0048] (c1) After adding 16 parts of chitosan sodium sulfonate, 7 parts of sodium hydroxide and 48 parts of water into the reactor, start stirring, and start to heat up, and react for 2 hours after the temperature reaches 95°C;

[0049] (c2) Add 18 parts of allyl glycidyl esters and 6 parts of (3-glycidoxypropyl) allyloxydimethoxysilane in the reactor, and start to drop the mass percent concentration of 2% sodium persulfate solution, the sodium persulfate solution is prepared from 0.1 parts of sodium persulfate and 4.9 parts of water; the dropping time is controlled at 3 hours, and the temperature is controlled at 108°C during the dropping; keep the temperature after the dropping Continue to react for 3 hours, cool down ...

Embodiment 2

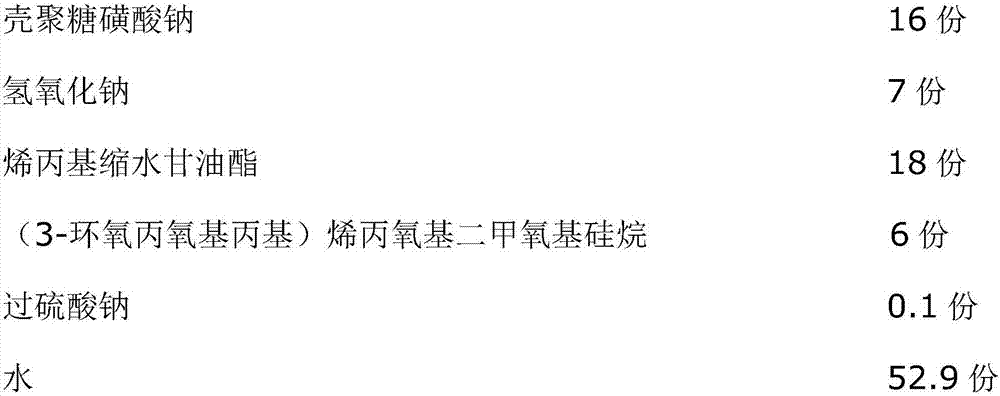

[0051] A kind of concrete synergist containing chitosan sodium sulfonate of the present invention, by weight, is made of following raw material component:

[0052]

[0053] A kind of preparation method of the concrete synergist containing chitosan sodium sulfonate of the present invention is realized through the following steps:

[0054] (d1) After adding 17 parts of chitosan sodium sulfonate, 8 parts of sodium hydroxide and 41 parts of water into the reactor, start stirring, and start heating and heating until the temperature reaches 98° C. and then react for 2.5 hours;

[0055] (d2) Add 17 parts of allyl polyoxyethylene epoxy ether and 7 parts of (3-glycidoxypropyl) allyloxydimethoxysilane to the reactor, and start dropping after adding A sodium persulfate solution with a mass percentage concentration of 3%, which is prepared from 0.3 parts of sodium persulfate and 9.7 parts of water; the dropping time is controlled at 3 hours, and the temperature is controlled at 110°C d...

Embodiment 3

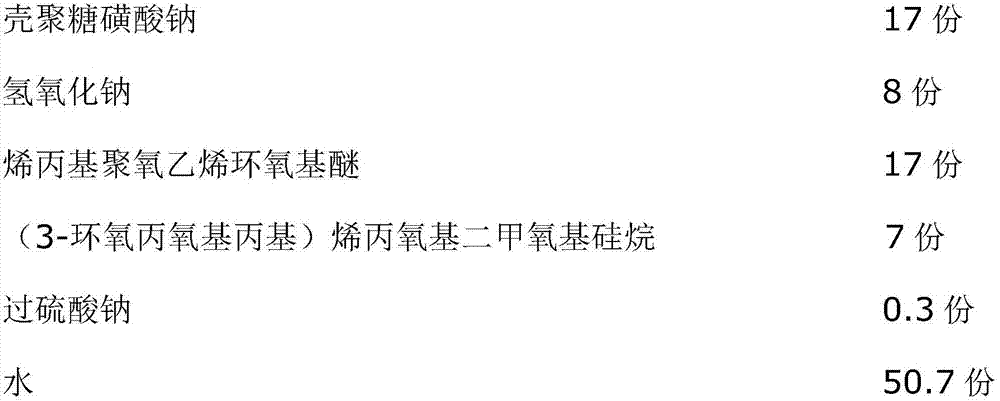

[0057] A kind of concrete synergist containing chitosan sodium sulfonate of the present invention, by weight, is made of following raw material component:

[0058]

[0059] A kind of preparation method of the concrete synergist containing chitosan sodium sulfonate of the present invention is realized through the following steps:

[0060] (e1) Add 18 parts of chitosan sodium sulfonate, 8 parts of sodium hydroxide and 46 parts of water into the reaction kettle, start stirring, and start to heat up, until the temperature reaches 101° C., react for 3.5 hours;

[0061] (e2) Add 17 parts of allyl polyoxyethylene polyoxypropylene epoxy ether and 7 parts of (3-glycidoxypropyl) allyloxydimethoxysilane to the reactor, after adding Start to add dropwise the potassium persulfate solution with a concentration of 6% by mass, which is prepared from 0.3 parts of potassium persulfate and 4.7 parts of water; the time for dropping is controlled at 3.5 hours, and the temperature is controlled ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com