Concrete synergist containing sulfonic acid group and preparation method thereof

A concrete synergist and sulfonic acid-containing technology, which is applied in the field of fine chemicals, can solve the problems that the economy and construction performance cannot be guaranteed, the cement strength cannot be effectively exerted, and the concrete is difficult to work again, and the conditions are mild and easy. , the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

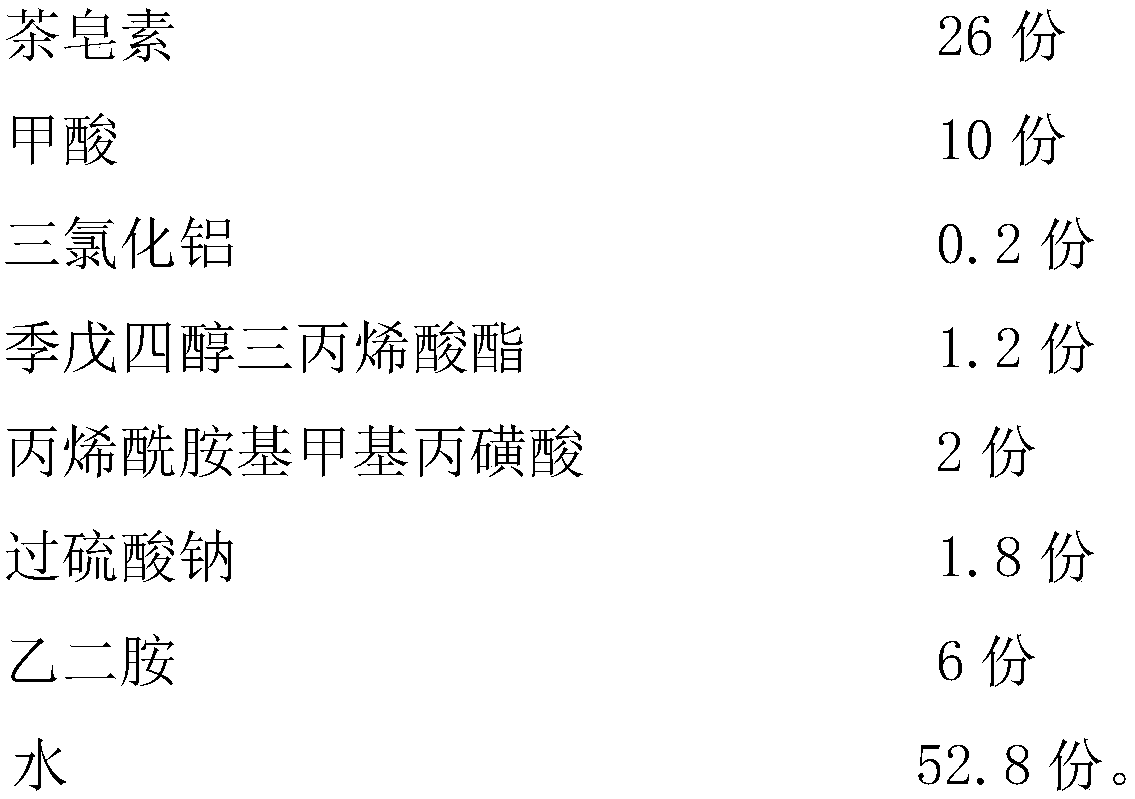

Embodiment 1

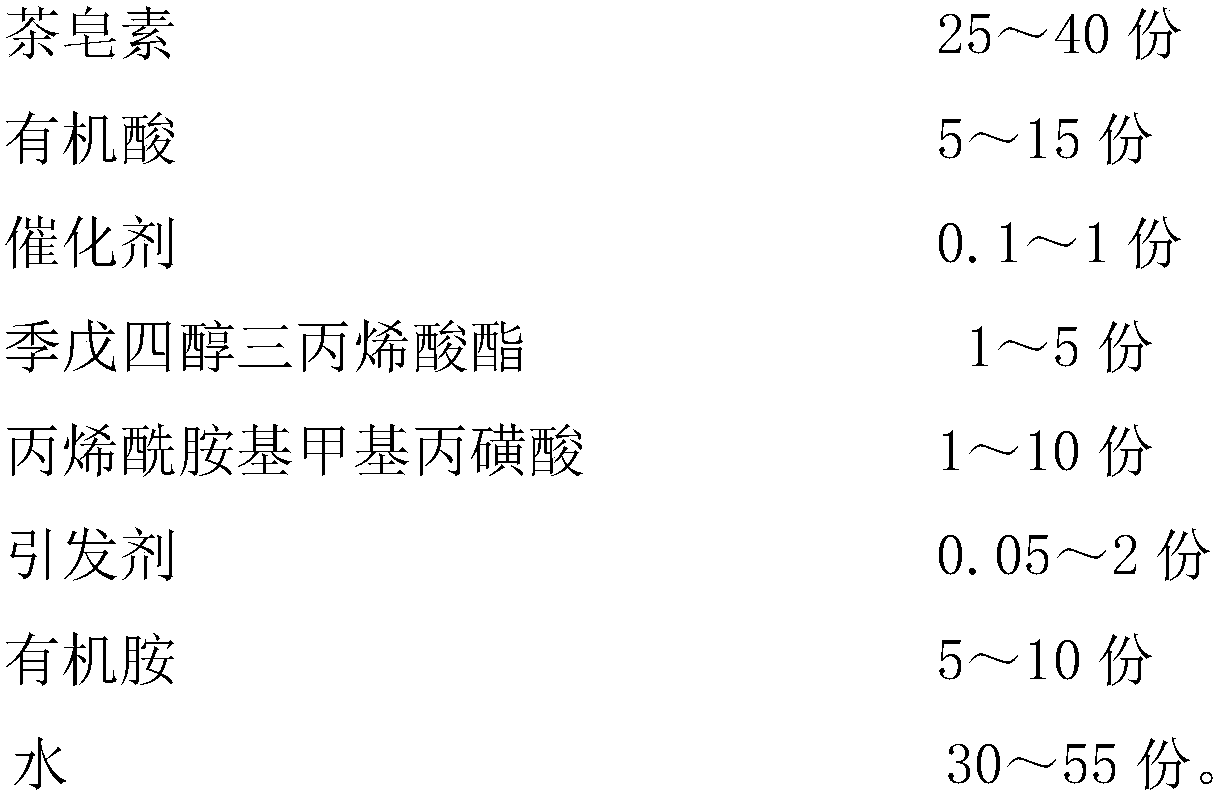

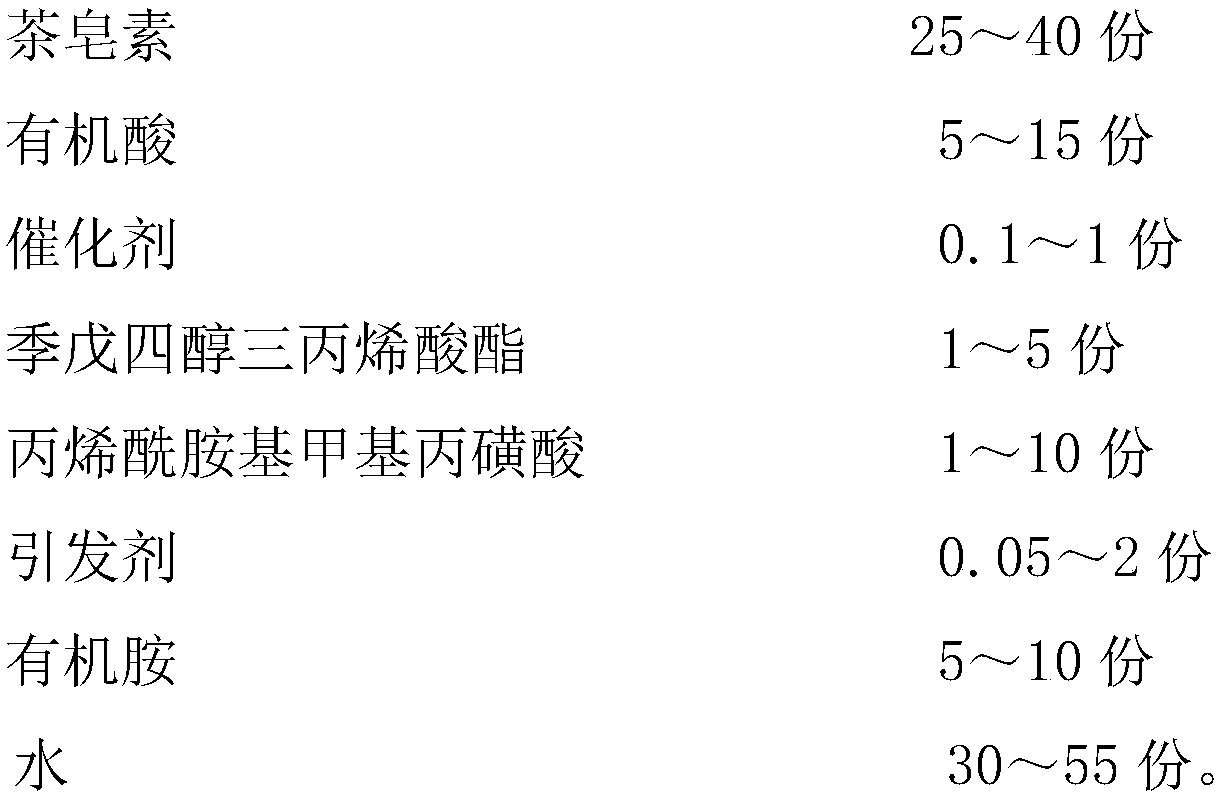

[0036] A concrete synergist containing sulfonic acid groups of the present invention is made of the following raw material components in proportions by mass:

[0037]

[0038] A kind of preparation method of the concrete synergist containing sulfonic acid group of the present invention, realizes by following steps:

[0039] (1) Put 26 parts of tea saponin, 10 parts of formic acid, and 0.2 parts of aluminum trichloride into the reaction tank, start stirring and raise the temperature, and react for 1.5 hours after the temperature rises to 102°C;

[0040] (2) Add 34.6 parts of water, 1.2 parts of pentaerythritol triacrylate, and 2 parts of acrylamidomethylpropanesulfonic acid into the reaction tank and stir for 0.6 hours;

[0041] (3) then dripping the sodium persulfate solution that the mass percent concentration is 9%, this sodium persulfate solution is formulated by 1.8 parts of sodium persulfate and 18.2 parts of water, and the dropping time is controlled at 3.2 hours, and...

Embodiment 2

[0044] A concrete synergist containing sulfonic acid groups of the present invention is made of the following raw material components in proportions by mass:

[0045]

[0046] A kind of preparation method of the concrete synergist containing sulfonic acid group of the present invention, realizes by following steps:

[0047] (1) Put 29 parts of tea saponin, 8 parts of formic acid, and 0.3 parts of aluminum trichloride into the reaction tank, start stirring and raise the temperature, and react for 2 hours after the temperature rises to 105°C;

[0048] (2) Add 29.2 parts of water, 2 parts of pentaerythritol triacrylate, and 3.5 parts of acrylamidomethylpropanesulfonic acid into the reaction tank and stir for 0.7 hours;

[0049] (3) then dripping the sodium persulfate agent solution that the mass percent concentration is 7.5%, this sodium persulfate solution is formulated by 1.5 parts of sodium persulfate and 18.5 parts of water, and the time of dropping is controlled at 4.5 ho...

Embodiment 3

[0052] A concrete synergist containing sulfonic acid groups of the present invention is made of the following raw material components in proportions by mass:

[0053]

[0054]

[0055] A kind of preparation method of the concrete synergist containing sulfonic acid group of the present invention, realizes by following steps:

[0056] (1) Put 32 parts of tea saponin, 8 parts of acetic acid, and 0.4 parts of ferric chloride into the reaction tank, start stirring and raise the temperature, and react for 3.2 hours after the temperature rises to 109°C;

[0057] (2) Add 23.1 parts of water, 2.5 parts of pentaerythritol triacrylate, and 5 parts of acrylamidomethylpropanesulfonic acid into the reaction tank and stir for 0.8 hours;

[0058] (3) then dripping mass percentage concentration is the potassium persulfate solution of 6%, this potassium persulfate solution is formulated by 1.2 parts of potassium persulfate and 18.8 parts of water, and the time of dropping is controlled at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com