Polypropylene or propylene-ethylene copolymer preparation method

A technology of propylene ethylene and polypropylene, which is applied in the field of propylene polymerization industrialization, can solve problems such as low equipment efficiency, uneven product quality, and small device scale, so as to reduce usage and cost, reduce energy consumption per unit product, and reduce plasticization Effect of Block Chance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

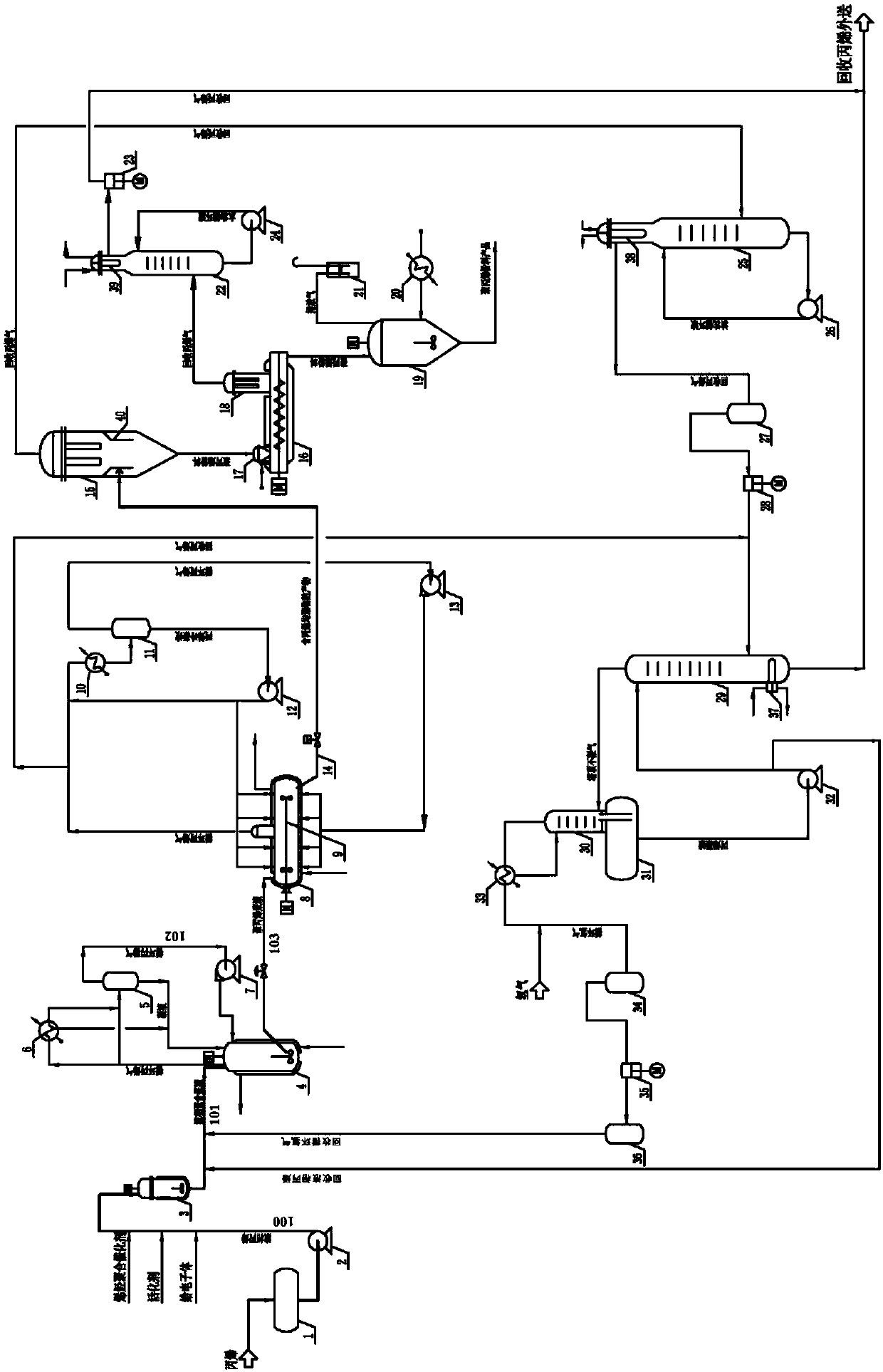

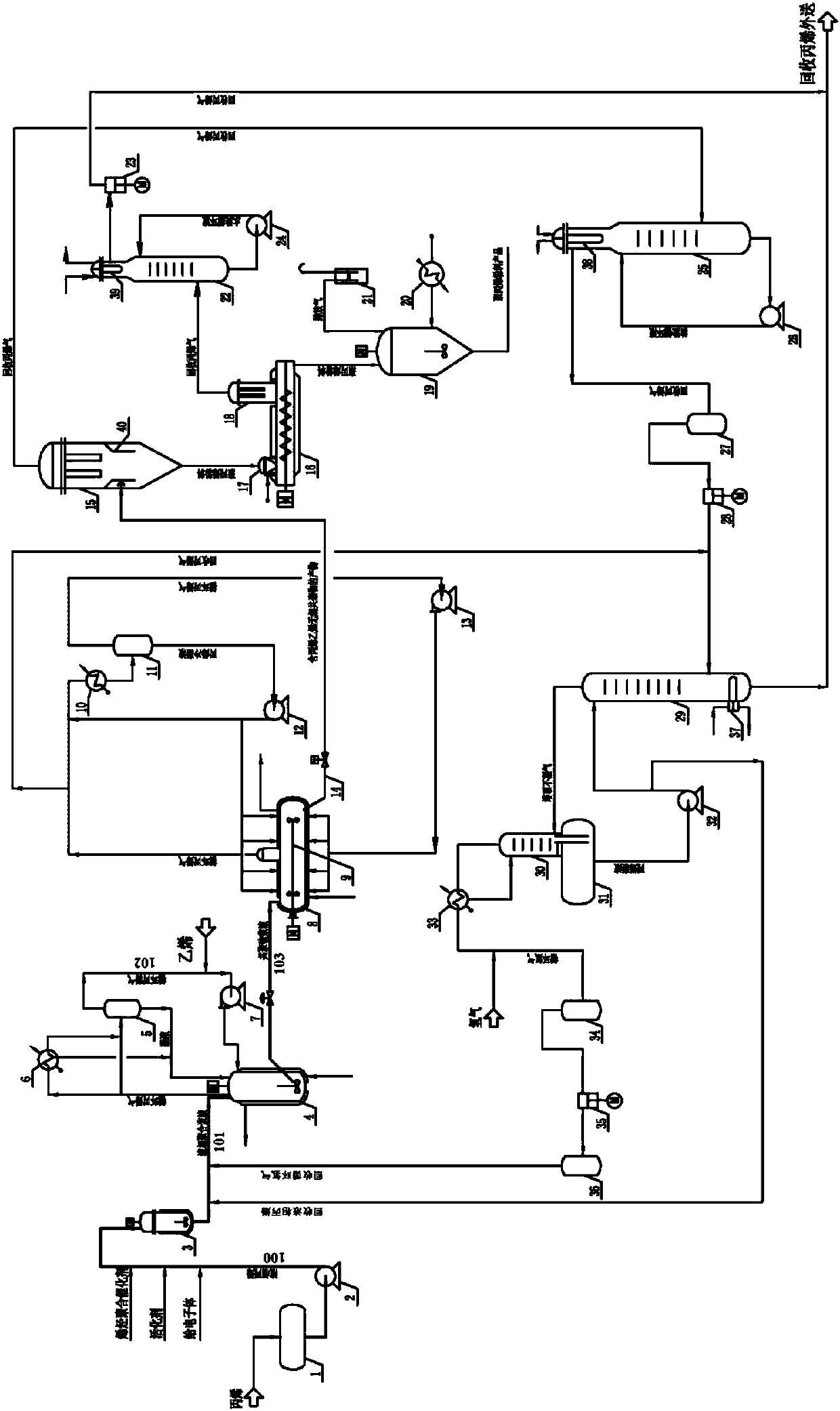

[0064] The present invention provides a kind of preparation method of polypropylene or propylene ethylene copolymer, such as figure 1 , figure 2 As shown, the method includes:

[0065] (1) feeding all the liquid-phase propylene containing the polymerization catalyst into a prepolymerization tank to carry out propylene prepolymerization to obtain a raw material slurry containing a propylene prepolymer;

[0066] Among them, the pre-polymerization temperature is 40-45°C, and the pre-polymerization pressure is 3.2-3.9 MPaG;

[0067] The polymerization catalyst includes an olefin polymerization catalyst, an activator and an electron donor, and the amount of the olefin polymerization catalyst is 0.04-0.06% by weight of the liquid-phase propylene;

[0068] (2) mixing the raw material slurry, recovered liquid phase propylene and recovered recycled hydrogen into a liquid phase polymerization raw material;

[0069] (3a) sending the liquid-phase polymerization raw material into a liq...

Embodiment 1

[0118] (1) Prepolymerization

[0119] Pressurize propylene to obtain liquid phase propylene with a pressure of about 4.2MPaG and a temperature of about 42°C; with liquid phase propylene as a carrier, Ti catalyst (CS-1) and 0.3 % by weight of triethylaluminum and 0.05% by weight of cyclohexylmethyldimethoxysilane; then all are directly input into the pre-polymerization tank to form a polymerization slurry, and then carried out at 42°C, 3.2MPaG, and a residence time of 4min Propylene pre-polymerization, the polymerization ratio of polypropylene in the obtained raw material slurry is 75 times;

[0120] (2) Liquid phase bulk polymerization

[0121] The raw material slurry obtained in (1) is added to recovery liquid phase propylene and hydrogen to form a liquid phase polymerization raw material (wherein the concentration of polypropylene is 200g / L, the recovery liquid phase propylene addition is about 25% by weight of the liquid phase propylene, and the hydrogen addition 0.08kg / 1...

Embodiment 2

[0129] (1) Prepolymerization

[0130] Propylene is pressurized to obtain liquid phase propylene with a pressure of about 4 MPaG and a temperature of about 45° C.; using liquid phase propylene as a carrier, adding Ti catalyst (CS-1) and 0.2 wt. % of triethylaluminum and 0.06% by weight of cyclohexylmethyldimethoxysilane; then all are directly input into the pre-polymerization tank to form a polymerization slurry, followed by propylene at 45°C, 3.6MPaG, and a residence time of 4min. Pre-polymerization, the polymerization ratio of polypropylene in the obtained raw material slurry is 50 times;

[0131] (2) Liquid phase bulk polymerization

[0132] The raw material slurry that (1) obtains is added reclaiming propylene and hydrogen to form liquid-phase polymerization raw material (wherein the concentration of polypropylene is 150g / L, reclaiming propylene add-on is about 27% by weight of liquid-phase propylene, and hydrogen add-on is 0.12kg / L 1000kg polypropylene), carry out liquid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com