Coal water slurry additive and preparation method thereof

A technology of coal-water slurry and additives, which is applied in the petroleum industry, liquid carbon-containing fuels, fuels, etc., can solve the problems of large environmental pollution and low fuel utilization rate, and achieve simple production process, convenient transportation and storage, and excellent fluidity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

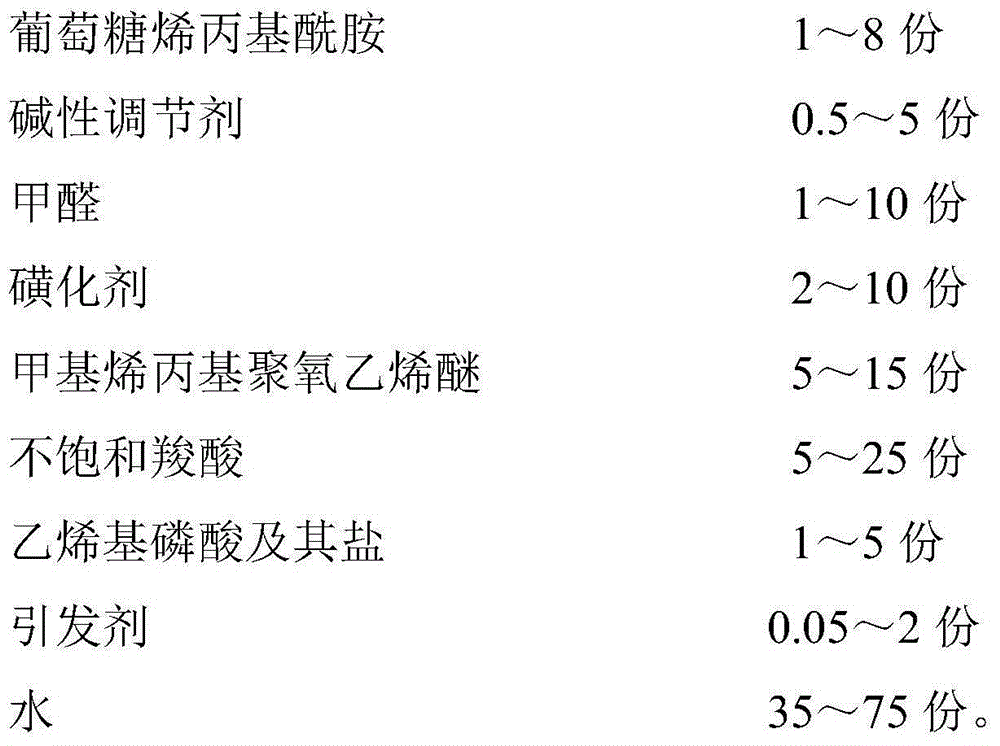

[0036] A kind of coal-water slurry additive of the present invention is made of the raw material component of following weight parts proportioning:

[0037]

[0038]

[0039] A kind of preparation method of coal-water slurry additive of the present invention, realizes by following steps:

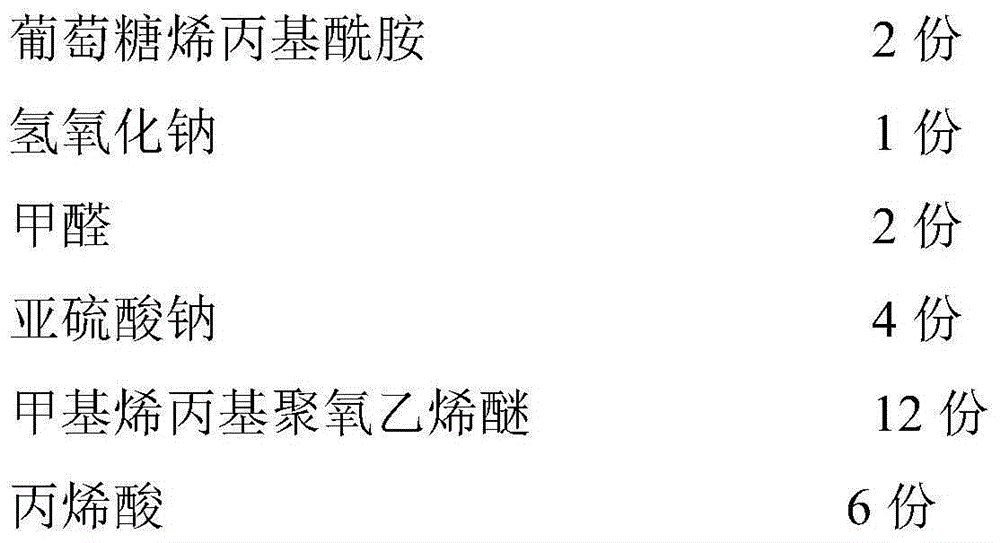

[0040] (1) Add 2 parts of glucose allylamide, 1 part of sodium hydroxide and 64 parts of water into the reactor, start stirring, and start heating;

[0041] (2) When the temperature rises to 58°C, add 2 parts of formaldehyde, continue the reaction for 0.15 hours, add 4 parts of sodium sulfite, and keep warm for 0.15 hours after the addition is completed;

[0042] (3) When continuing to heat to 76°C, add 12 parts of methallyl polyoxyethylene ether, 6 parts of acrylic acid, and 2 parts of vinyl phosphoric acid, and start to drop the initiator solution with a mass percentage concentration of 2% after stirring evenly , the initiator solution is prepared from 0.1 parts of sodium persulfate...

Embodiment 2

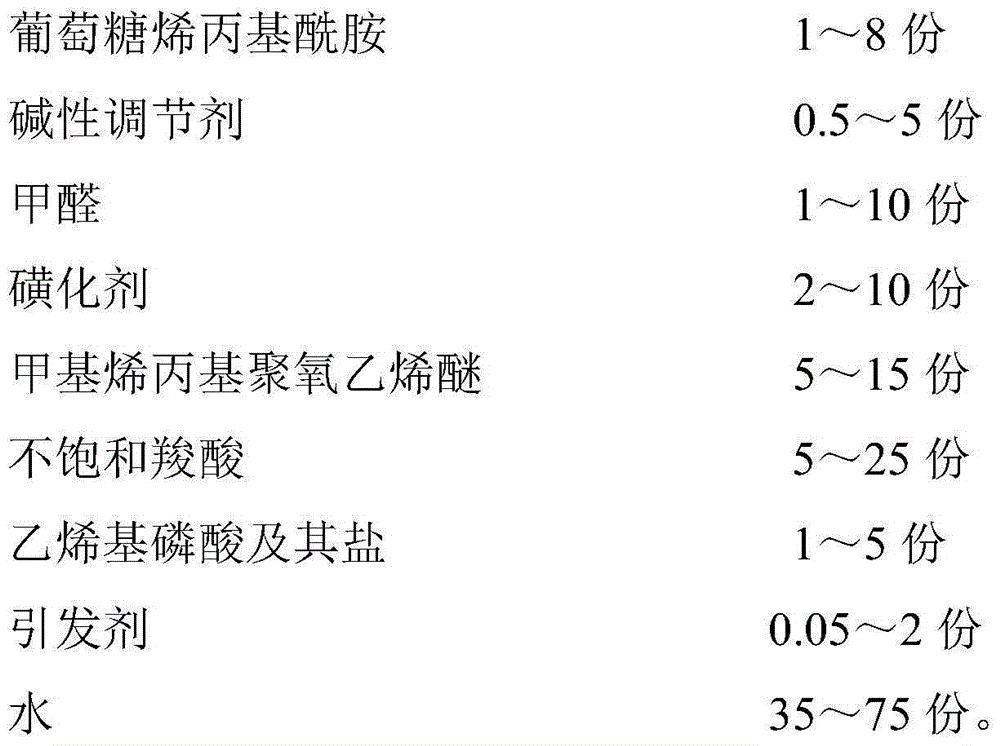

[0045] A kind of coal-water slurry additive of the present invention is made of the raw material component of following weight parts proportioning:

[0046]

[0047] A kind of preparation method of coal-water slurry additive of the present invention, realizes by following steps:

[0048] (1) Add 3 parts of glucose allylamide, 2 parts of potassium hydroxide and 66 parts of water into the reactor, start stirring, and start heating;

[0049] (2) When the temperature rises to 65°C, add 2 parts of formaldehyde, continue the reaction for 0.2 hours, add 4 parts of sodium metabisulfite, and keep warm for 0.3 hours after the addition;

[0050] (3) When continuing to heat to 85°C, add 13 parts of methallyl polyoxyethylene ether, 6 parts of methacrylic acid, and 2 parts of sodium vinyl phosphate, and after stirring evenly, start to add the Initiator solution, which is prepared from 0.1 parts of potassium persulfate and 1.9 parts of water; the dropping time is controlled at 2 hours, a...

Embodiment 3

[0053] A kind of coal-water slurry additive of the present invention is made of the raw material component of following weight parts proportioning:

[0054]

[0055] A kind of preparation method of coal-water slurry additive of the present invention, realizes by following steps:

[0056] (1) Add 5 parts of glucose allylamide, 3 parts of sodium carbonate and 38.5 parts of water into the reactor, start stirring, and start heating;

[0057] (2) When the temperature rises to 60°C, add 5 parts of formaldehyde, continue the reaction for 0.5 hours, add 5 parts of sodium bisulfite, and keep warm for 0.5 hours after the addition is completed;

[0058](3) When continuing to heat to 85°C, add 13 parts of methallyl polyoxyethylene ether, 15 parts of acrylic acid, and 3 parts of vinyl phosphate potassium salt. Agent solution, this initiator solution is prepared from the 0.5 parts of ammonium persulfate and 12 parts of water; the dropping time is controlled at 2.5 hours, and the tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com