Dichlorodiphenyl-stannane complex and preparation method and application thereof

A technology of diphenyltin dichloride and complexes, which is applied in the direction of botany equipment and methods, tin organic compounds, applications, etc., can solve the problems of low cost, unscreened or developed herbicidal activity, etc., and achieve low cost, Simple preparation method and high water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

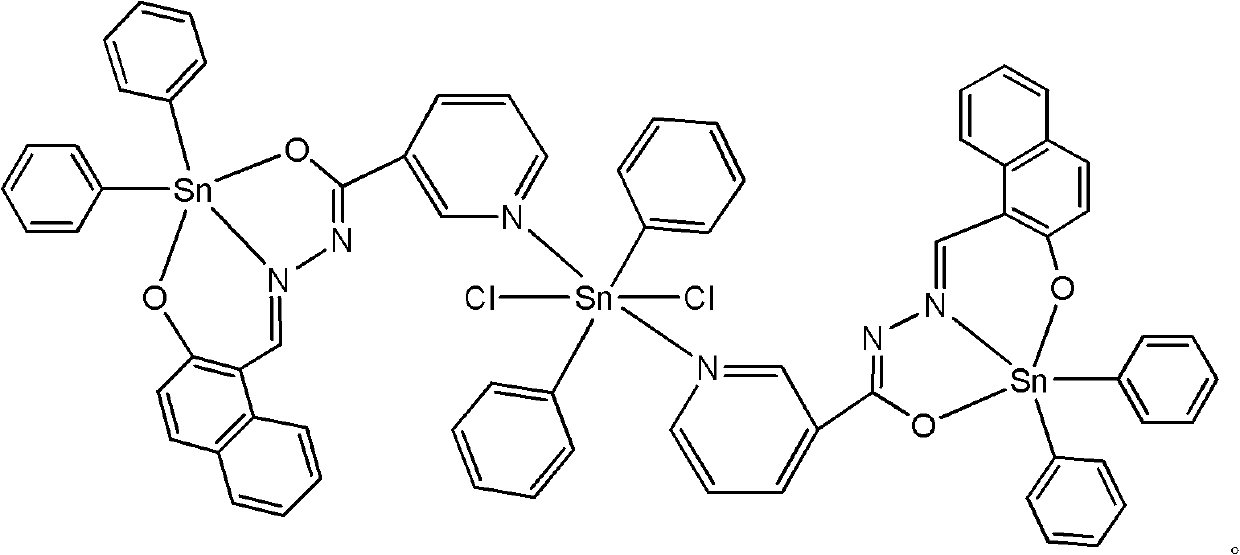

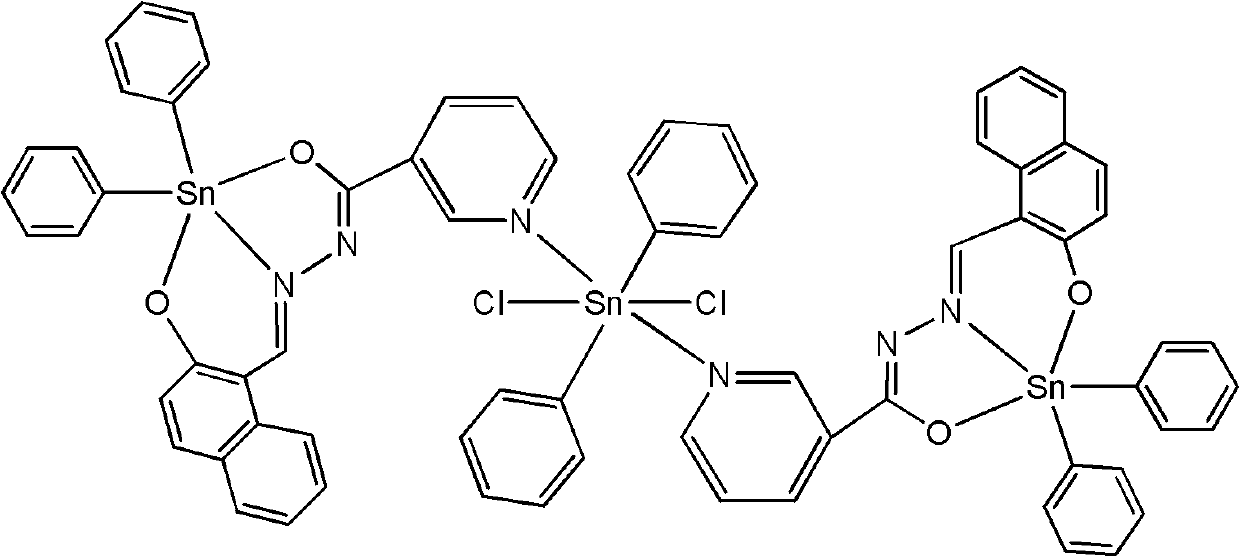

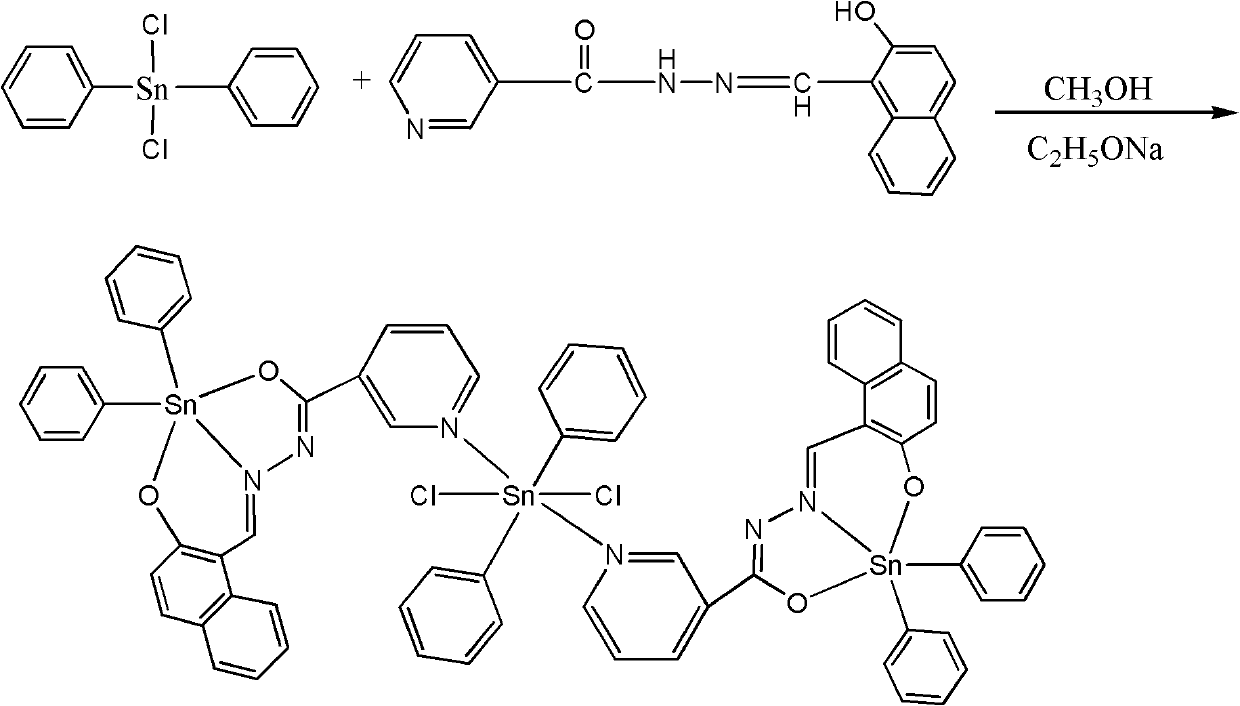

Image

Examples

Embodiment 1

[0013] Example 1: Preparation of diphenyltin dichloride complex: add 1.0mmol of 2-hydroxy-1-naphthalene-3-pyridylhydrazone, 1.0mmol of sodium ethoxide, and 1.0mmol of dibutyltin oxide to the flask and 20ml of methanol, stirred and refluxed at 65±1°C for 7 hours, cooled to room temperature, and rotovaped to obtain a yellow solid; recrystallized with dichloromethane-ethanol (the volume ratio of dichloromethane to ethanol is 1:1), to obtain The yellow transparent crystal is an organotin coordination compound, and the yield is 75%.

[0014] Through infrared spectrum analysis and NMR analysis, the results are as follows:

[0015] Infrared spectrum (KBr, cm -1 ): 1610 (m, C=N), 1590 (s, C=N-N=C), 564 (w, Sn-O), 475 (m, Sn-N).

[0016] 1 H NMR (CDCl 3 , ppm): δ8.88 (2H, m, N=CH), 7.26-9.23 (8H, m, pyridine-H), 7.08-7.21 (12H, m, naph-H); 6.89-7.06 (30H, m , Ph-H); 13 C-NMR (CDCl 3 , ppm): 163.7 (CH=N), 163.89 (CO-N), 152.1, 150.3, 137.2, 126.3, 123.9 (pyridine-C), 135.1, 132.4...

Embodiment 2

[0018] Example 2: Preparation of diphenyltin dichloride complex: add 1.0mmol of 2-hydroxy-1-naphthalene-3-pyridylhydrazone, 1.2mmol of sodium ethoxide, and 1.5mmol of dibutyltin oxide to the flask and 30ml of methanol, stirred and refluxed at 65±1°C for 7 hours, cooled to room temperature, and rotovaped to obtain a yellow solid; recrystallized with dichloromethane-ethanol (the volume ratio of dichloromethane to ethanol is 2:1), to obtain The yellow transparent crystal is an organotin coordination compound, and the yield is 78%.

Embodiment 3

[0019] Example 3: Preparation of diphenyltin dichloride complex: add 1.0mmol of 2-hydroxy-1-naphthalene-3-pyridylhydrazone, 1.5mmol of sodium ethoxide, and 1.0mmol of dibutyltin oxide to the flask and 30ml of methanol, stirred and refluxed at 50±1°C for 6 hours, cooled to room temperature, and rotovaped to obtain a yellow solid; recrystallized with dichloromethane-ethanol (the volume ratio of dichloromethane to ethanol is 2:1), to obtain The yellow transparent crystal is an organotin coordination compound, and the yield is 70%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com