Cold extrusion moulding process of aluminium alloy complex cup-shaped thin-wall part

A forming process, cold extrusion technology, applied to engine components, mechanical equipment, etc., can solve the problems of long production cycle, large amount of machining, low material utilization rate, etc., to reduce raw material consumption, reduce forging process, rough surface The effect of high degree and dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

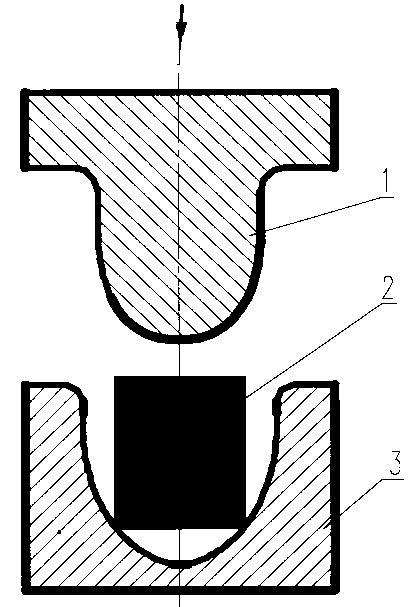

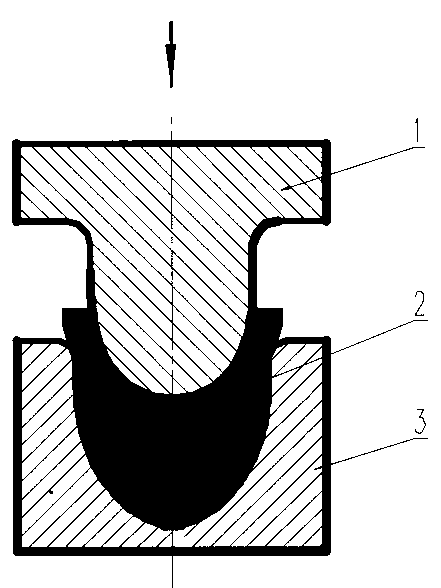

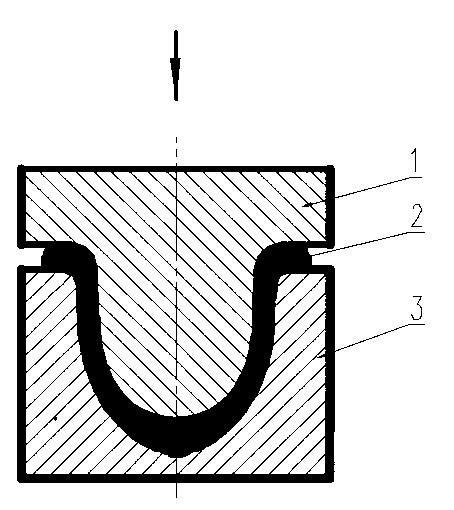

[0016] This embodiment provides a cold extrusion forming process for aluminum alloy complex cup-shaped thin-walled parts, which is characterized in that: the cold extrusion forming process for aluminum alloy complex cup-shaped thin-walled parts is as follows: Installed on the forging equipment, choose 3150T electric screw press, or 2500T hydraulic press, adjust the mold gap and misalignment, lubricate the mold with lubricant industrial lard; adjust the equipment, when using 3150T electric screw press, adjust its striking energy to 30%; then at room temperature, put the cold round bar with a diameter of 200mm and softened into the die; under the pressure of the equipment, the metal flows in the die until the cavity is filled, and the excess metal is then Reverse extrusion between the convex and concave dies to form the flange edge at the opening of the forging; after the equipment stroke is completed, the metal no longer flows to form the shape and size of the final cold extrusi...

Embodiment 2

[0021] This embodiment provides a cold extrusion forming process for aluminum alloy complex cup-shaped thin-walled parts, which is characterized in that: the cold extrusion forming process for aluminum alloy complex cup-shaped thin-walled parts is as follows: Installed on the forging equipment, choose 3150T electric screw press, or 2500T hydraulic press, adjust the mold gap and misalignment, lubricate the mold with lubricant industrial lard; adjust the equipment, use 2500T hydraulic press, the energy is maintained at the maximum, and the speed is 2-8mm / s; then at room temperature, put the cold round bar with a diameter of 200mm and softened into the die; under the pressure of the equipment, the metal flows in the die until it fills the cavity, and the excess metal is returned to the die. Squeeze between the convex and concave dies to form the flange edge at the opening of the forging; after the equipment travels, the metal will no longer flow, forming the shape and size of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Corner radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com