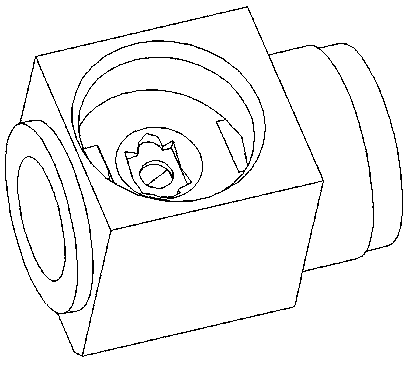

Gpon optical network component structural part

A technology of optical network and structural parts, applied in the field of powder metallurgy, can solve problems such as unstable machining accuracy, achieve the effects of improving dimensional accuracy and surface roughness, saving materials, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Depend on figure 1 It is known that it is the Gpon optical network device for optical communication of the product of this embodiment. Its production process is:

[0015] 1. Take: 88 parts of stainless steel powder; 5 parts of wax, 2.2 parts of polypropylene, 6.3 parts of low-pressure polyethylene, 4.3 parts of thermoplastic elastomer; first add stainless steel powder and wax to the high mixer, stir at 600-650rpm at a low speed, and heat to Add polypropylene, low-pressure polyethylene and thermoplastic elastomer at 60-65°C, mix and continue to stir and heat, so that the temperature is controlled at 170-200°C, and the time is controlled at 20-30 minutes. After discharging, cut the mixed material into pieces, cool, Broken, bagged, and stored for later use;

[0016] 2. Injection molding: The above-mentioned mixed materials are injected into the blank by the injection molding machine through the mold. The technical conditions are: the mold temperature is controlled at 35...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com