Method for manufacturing polypropylene woven water tape and products thereof

A manufacturing method and technology of polypropylene, applied to tubular objects, other household appliances, hoses, etc., can solve problems such as high price, thick hose, and damaged hose, so as to reduce raw material consumption, prolong service life, reduce effect of weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The manufacture method of polypropylene braided hose, it comprises the steps:

[0022] (1) adopt polypropylene (PP) new material t30s or 5000s, according to the t30s or 5000s of 100 parts by weight, mix and add the antioxidant 1010 that is 0.4 parts by weight, the UV-327 that is 0.5 parts by weight, the parts by weight is 0.6 parts of auxiliary antioxidant DLTP;

[0023] (2) putting the product obtained in step (1) into a dryer for drying;

[0024] (3) the product obtained in step (2) is drawn with a plastic wire drawing machine;

[0025] (4) the product that step (3) obtains is carried out weft silk location with plastic thread winding machine;

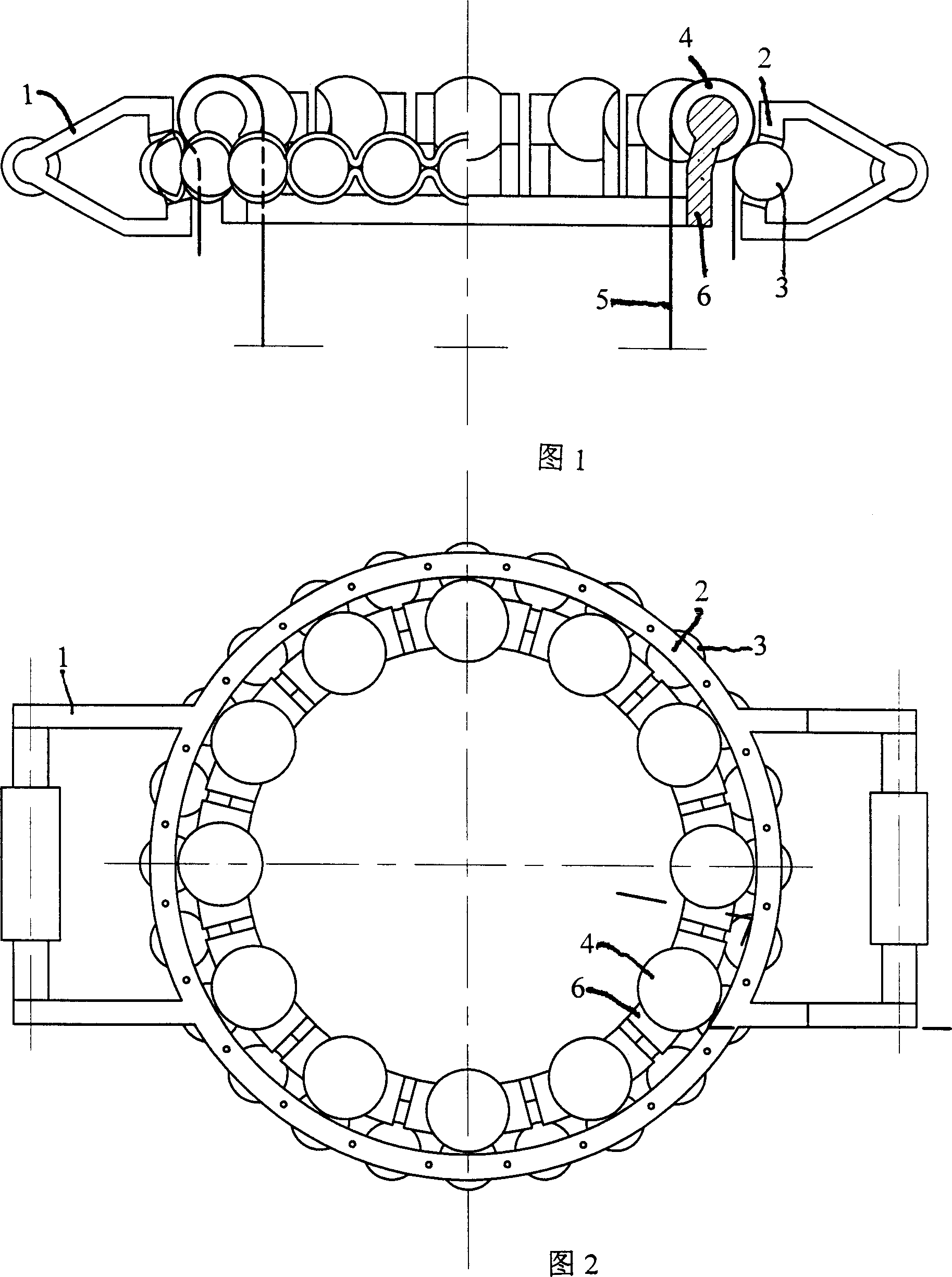

[0026] (5) the product obtained in step (4) is woven into a tubular hose with a plastic circular loom;

[0027] (6) The product obtained in step (5) is first coated with a plastic film on its outer surface with a cylindrical woven bag plastic-coating compound machine, and then the inner surface of the tubular hose is turned...

Embodiment 2

[0032] The manufacture method of polypropylene braided hose, it comprises the steps:

[0033] (1) adopt polypropylene (PP) new material t30s or 5000s, according to the t30s of 120 parts by weight or 5000s, mix and add the antioxidant 1010 that is 0.3 parts by weight, the UV-327 that is 0.4 parts by weight, the parts by weight is 0.72 parts of auxiliary antioxidant DLTP;

[0034] (2) putting the product obtained in step (1) into a dryer for drying;

[0035] (3) the product obtained in step (2) is drawn with a plastic wire drawing machine;

[0036] (4) the product that step (3) obtains is carried out weft silk location with plastic thread winding machine;

[0037] (5) the product obtained in step (4) is woven into a tubular hose with a plastic circular loom;

[0038] (6) The product obtained in step (5) is first coated with a plastic film on its outer surface with a cylindrical woven bag plastic-coating compound machine, and then the inner surface of the tubular hose is turne...

Embodiment 3

[0042] The manufacture method of polypropylene braided hose, it comprises the steps:

[0043] (1) adopt polypropylene (PP) new material t30s or 5000s, according to the t30s of 80 parts by weight or 5000s, mix and add the antioxidant 1010 that is 0.5 parts by weight, the UV-327 that is 0.6 parts by weight, the parts by weight is 0.72 parts of auxiliary antioxidant DLTP;

[0044] (2) putting the product obtained in step (1) into a dryer for drying;

[0045] (3) the product obtained in step (2) is drawn with a plastic wire drawing machine;

[0046] (4) the product that step (3) obtains is carried out weft silk location with plastic thread winding machine;

[0047] (5) the product obtained in step (4) is woven into a tubular hose with a plastic circular loom;

[0048] (6) The product obtained in step (5) is first coated with a plastic film on its outer surface with a cylindrical woven bag plastic-coating compound machine, and then the inner surface of the tubular hose is turned...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com