Production device of wall tube of large aperture framework-tube polyethylene winding structure

A technology for structural wall pipes and production equipment, applied in the direction of tubular objects, applications, household appliances, etc., can solve the problems of product weight, high raw material consumption, high cost, etc., and achieve the effect of less raw material consumption, low cost, and reduced weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

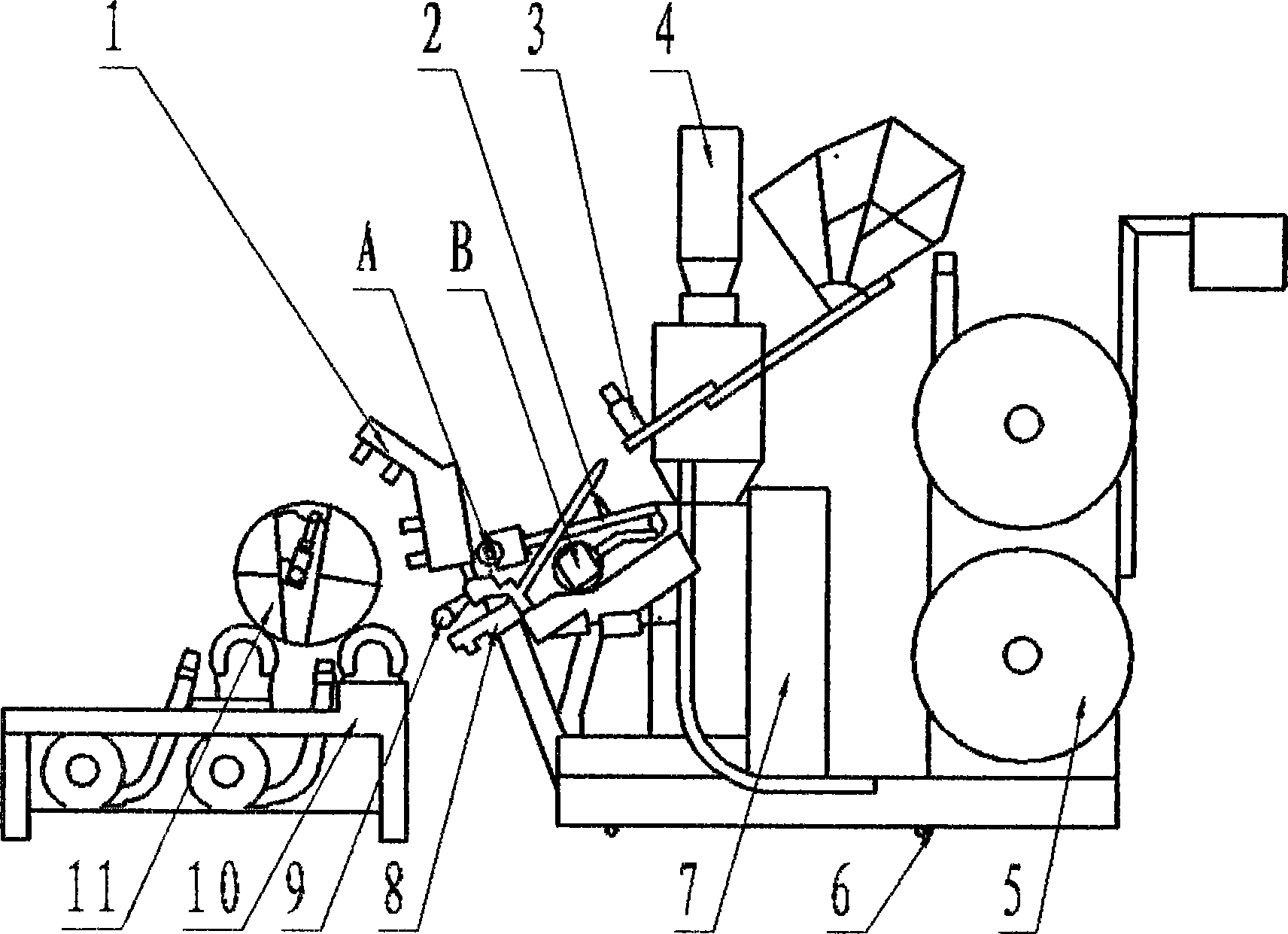

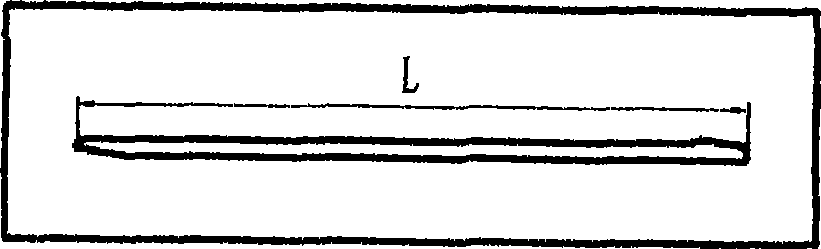

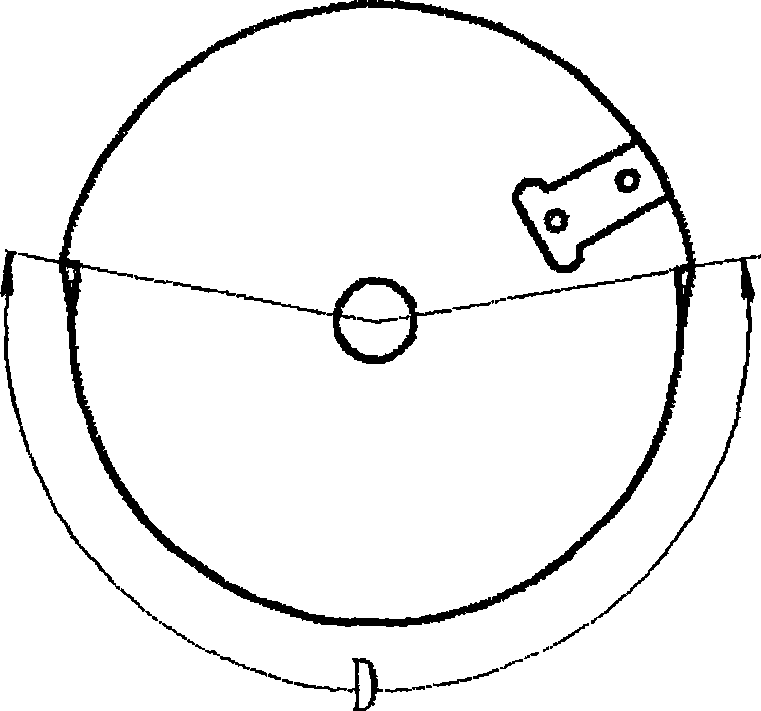

[0011] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments: the present invention is realized through a technical scheme of a large-diameter skeleton pipe polyethylene winding structure wall pipe production line, which mainly includes an extruder 4, a combustion system 1, and a skeleton The pipe reel 5, the skeleton pipe conveying system 3 and the electrical control cabinet 7 are respectively fixed on the mobile trolley 6, the extruder 4 is connected to the runner system 2, the circulating cooling device 8, the pressure frame 9, and the roller mold 11 is placed on the rotating On the roll stand 10, a set of pipe material production line equipment is formed. After the diameter of the skeleton pipe is increased by DN80mm, the extrusion of high-density polyethylene broadband by the flat die and the covering die of the existing plastic pipe manufacturing equipment cannot meet the requirements. The ut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com